Brian Fritz, vice president of business development at AutoGate, looks at the advantages of vertical pivot gate systems in vehicular control, security, and safety.

Automatic gates and fencing are a cornerstone of perimeter security. For commercial and industrial buildings in particular, slide gates are quite common. But there is another style that offers more advantages and unique features: the vertical pivot gate (VPG).

Here’s why you should consider a VPG over a slide or swing gate system.

What is a Vertical Pivot Gate?

VPGs are automatic vehicular gate systems that open and close with the same motion of a railroad crossing arm. They offer considerable security, safety, and space saving advantages compared to sliding gates. VPGs have been in production for over four decades, and the ease of pivot gate installation reduces the need for highly experienced installers and substantially eases the burden of specifiers during project design and construction phases.

Why Should I Spec a Vertical Pivot Gate?

Understandably, anything new raises questions and may give pause to change your buying habits. Change occurs when the value drivers are met, and advantages are recognized. I think the key advantages of VPGs are their speed to process vehicles, reduced areas pedestrians can be injured, reduced issues with problematic functionality, increased security features, and certainly lower cost of ownership.

See Also: How Fiberglass Windows Improve Building Performance

VPGs are made custom to site needs and deliver the common need of security and processing vehicles like other gates. However, VPGs can also be tailored to other details and desires of a project as needed without having to rely on experienced subcontractor solutions or requiring additional scopes of work for the project. The VPG is simply that versatile of a product.

This fraternity at the University of Alabama uses a vertical pivot gate to control access for residents while not compromising the surrounding aesthetics. It also provides a reduced path of interference with pedestrians. Photo courtesy of AutoGate

How are Vertical Pivot Gates Different from Other Gating Systems?

They fix a set of common denominators like bad installations and cutting corners due to negligence or ignorance. VPG manufacturers produce both the operator and the gate panel and ensure the gate is not only fabricated to gate safety standards but also construct the gate to match site aesthetics and thoroughly test the operation of the system before it ships. The system arrives to the owner’s site nearly ready to operate.

Manufacturers of slide gate operators and swing gate operators do not fabricate the gate panels that attach to the operator. Slide and swing gate operators are manufactured and placed in boxes and stored in warehouses until ordered. Typically, the gate panels are made by a local fabricator who you hope knows at least some details of the project and the safety standards required for that gate system. The specifier and the owner are completely reliant on the installer to know, understand, and meet safety standards and project specifications.

In contrast, VPGs are ordered in a collaborative fashion by quickly exchanging information on material dimensions, safety features, operational qualities, electrical requirements, and optional accessories. This ensures less issues from the installer error, incompatible components, quality shortcomings, deviation from specifications, and increased owner satisfaction.

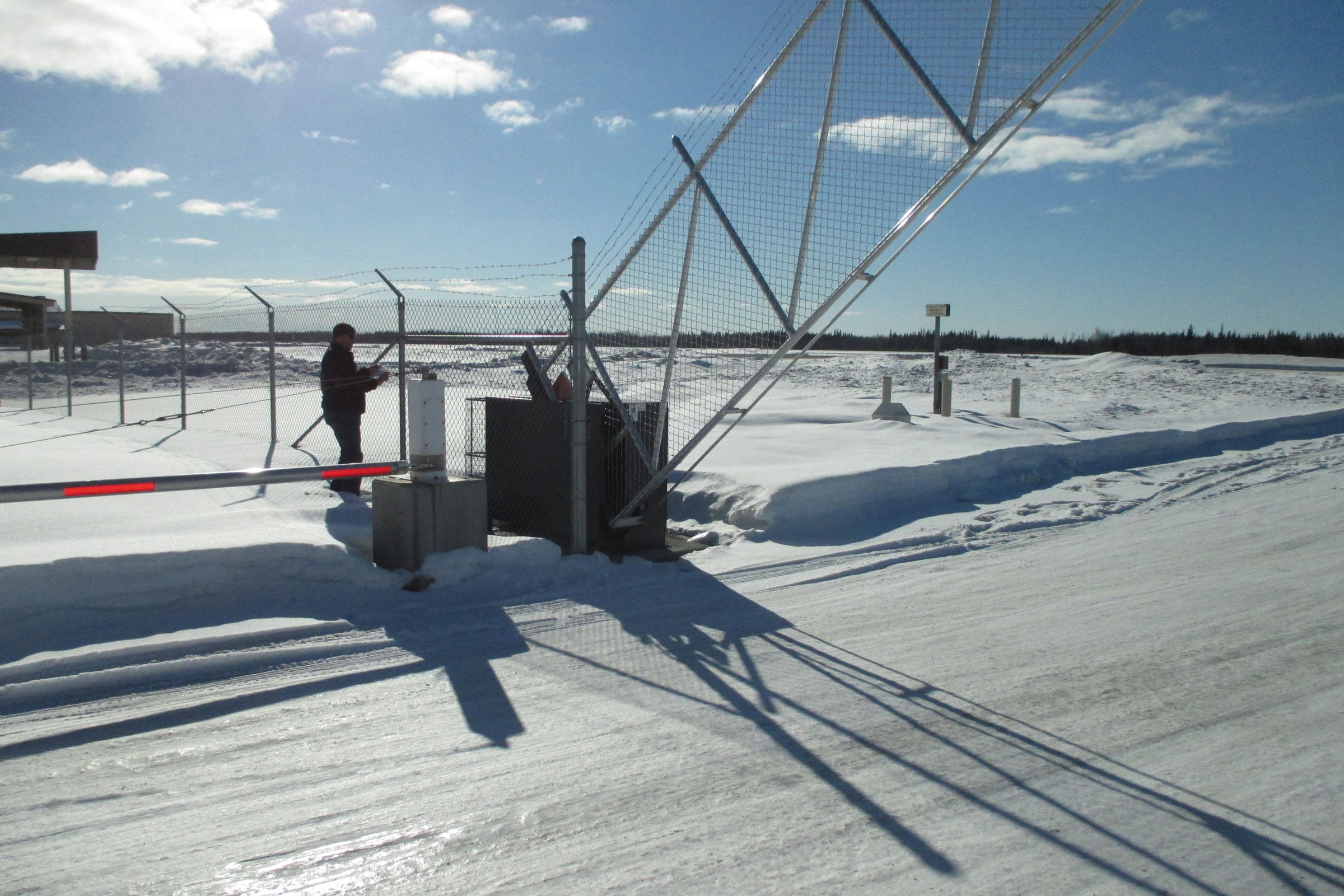

Vertical pivot gates do not need to track through the snow, as shown at this Air Force Base in Alaska. This ensures the gate will not only be able to open but also not burden the operator or safely compromise the gate system due to adverse conditions. Photo courtesy of AutoGate

What Problems Can Vertical Pivot Gates Fix?

VPGs are the most adaptive gate system for common access point conditions and particularly those that challenge designers and other gate systems. Some challenges include working around curbs, road elevation and contour changes, drainage swales, and more. This is because the gate panel is fabricated specifically to conform with exact spacing when closed over site conditions.

Slide gates do not have this ability, which causes both aesthetic and security issues because they cannot conform to the site. Slide gates cannot match grade changes and often leave unsightly gaps that invite security breaches. Pivot gates can easily meet rigid security standards, such as DoD standards, in which the bottom of the gate panel shall not exceed 2 inches above drive grade. Slide gates require the installer and owner to design the site to compensate for what a slide gate cannot do, while VPGs are simply made to fit like a glove in all aspects.

VPGs also open and close much faster than slide and swing gates. This delivers a faster vehicular processing speed and greater volume of traffic at access points. Slide gates commonly open and close at 1 to 1.5 inches of gate length per seconds while VPGs commonly open or close in 8 to 10 seconds. By having a pivot point the length of gate does not affect the time it takes for a pivot gate to open. Realistically, a slide gate can only process about one vehicle a minute while VPGs can process two or three per minute. This is important in high volume or peek traffic locations and situations. Slower gates encourage tailgating, which occurs when trying to follow other vehicles through a gate without using access control systems and often leads to security breaches and accidents where the gate is hit and vehicle damage occurs. A common saying in the gate industry is, “It’s not if a gate will be hit, it’s when.”

Slide and swing gates are attached to fence lines and support posts. This means more is damaged or destroyed than just the gate on impact. Slide and swing gate operators, posts, and the adjacent fence line are damaged or destroyed as well. This damage compromises the use of the access point and is far more costly to repair. Conversely, VPGs have gates that are bolted to the operator and designed for only the gate to be damaged. In fact, most gate strikes do not shut down the site and are quickly repairable back to the original aesthetic and quality prior to the impact.

Vertical pivot gates can easily cover over curbs and non-level conditions under the gate. Each gate is made to fit the site. Photo courtesy of AutoGate

Are Vertical Pivot Gates Safe?

Automated Gate systems are governed two safety standards: UL 325: Standard for Door, Drapery, Gate, Louver, and Window Operators and Systems and ASTM F2200: Standard Specification for Automated Vehicular Gate Construction. Both standards are required in fire and building codes and focus on pedestrian safety around a gate system. I believe pivot gate systems have substantially less entrapment areas and less danger points than do slide and swing gates. Slide gates in particular require extensive mitigation of areas a person can be injured or entrapped.

Unfortunately, many installers know this, and it’s a common issue of either ignorance, negligence, or laziness to promote safe operation. It can be a cost control mechanism to help win a bid or a corner cutting solution to ensure the gate opens and closes regardless of safety concerns. In either case this exposes pedestrians to injury and the specifier and owner to liability if there is an incident or death.

Because slide gates are attached to posts, columns, or other structural devices they create numerous pinch points and areas where a person can be struck, pinched, or pulled into areas between a moving gate and a fixed object like a post, fence, or column. Slide gates cover much more area to fully open and close. Slide gates require extensive space to accommodate the full length of the gate panel at any point of being open, closed, or moving. Pivot gates move the gate panel up and away from anywhere pedestrians can be and require far less space to operate than slide gates. Additionally, pivot gates and operators are manufactured together, ship together, and arrive with minimal remaining tasks to complete the required UL 325 & ASTM F2200 safety standards compliance and other accessory installation. Much of this work and assembly is conducted by the manufacturer ensuring proper operation and configuration.

Urban placement of gate systems is often challenged by space availability to open and close and can compromise pedestrian safety or security issues. This inner-city vertical pivot ornamental gate offers the aesthetic desired while prohibiting someone from climbing under the gate due to curb notching. Photo courtesy of AutoGate

How are Vertical Pivot Gates Maintained?

I think there is a significant importance in what it takes to keep a gate system functioning properly. This is tied directly to both safety and total cost of ownership.

Ultimately all gates systems are machines and require maintenance. A significant advantage of a pivot gate system is that the components that operate the gate are inside the operator and protected from the elements. Some components of a slide gate are inside the operator, but several key components remain exposed and need adjustment and maintenance to remain in qualitative operation.

Unfortunately, the most common time maintenance and adjustment occurs is at or following issues and breakdowns. External to slide gate systems are the safety or entrapment protection devices such as photo eyes and contact sensors and the chains or rail needed to move the gate. Slide gate systems require many more entrapment protection devices than do pivot gates. As such, many more potential weak links are built into the system and will require attention and upkeep.

Slide gates also often have issues associated with chains and drive rail systems. Environmental factors, along with daily use, can cause limitations in opening and closing slide gate. The drive chain must be lubed, tensioned correctly, and kept free of debris and ice or you reduce the chain and operator’s life. Each operator manufacturer has its own specs on how to tension the drive chain, which is often ignored. Slide gate operators that use rail attached horizontally along the gate to grab and drive it open and close have known issues. The rail must be kept free of debris, ice, and remain securely attached and in proper alignment with the operator. The wheels that drive the rail must be maintained, tensioned, and adjusted often or it will lead to operational and safety issues requiring a gate technician to restore the system to proper configuration. This can be quite expensive and repetitive.

Again, the pivot gate system is fully produced by the manufacturer. It leaves the factory ready to operate, fully configured, and tested to avoid issues of improper installation.

What are Next Steps in Specifying a Vertical Pivot Gate System?

Your gate manufacturer will ask common questions to design the right VPG for you. Questions may include:

- What is the size of the gate panel desired?

- Are there are any special materials for gate construction?

- What is the geographic area like?

- How you intend to control the gate?

- Who will use the gate—employees, truck traffic, or others?

- What types of vehicles will use the gate?

- Are emergency access provisions needed for first responders?

- Are there are any applicable security standards that impact the design of the gate?

After this exchange of information, we will assist and collaborate on all your design needs to ensure that the gate system that arrives on site exceeds the needs of the vehicle access point.