Story at a glance:

- Viega’s press technology allows for the same reliable pipe connection every time.

- ProPress and MegaPress are safer and more durable than traditional systems.

- This guide explores Viega’s new and current most popular products.

Viega has been manufacturing press fittings for more than 120 years, and in the last couple of decades they’ve made incredible strides—creating a technology to efficiently, safely, and quickly connect pipes in the US.

“We keep our product to the highest quality standards, both for the installers and the people who have it in their buildings,” says Colton Henkowski, a Viega technical training consultant who trains contractors, engineers, and wholesale reps through in-person and online workshops.

Henkowski has worked as a pipefitter for 15 years and has more than a dozen welding certifications. He often used these fittings in the field even before he joined the Viega team. He says the competition simply doesn’t live up to what Viega offers.

If not for Viega’s press technology, installers would have to do a much more dangerous and tedious process, he says. When you have to solder a joint, for example, you have to shut down the fire system and have a fire extinguisher, gloves, glasses, and fire protection on-hand. It all takes time, Henkowski says. “And then when you’re creating a solder joint it’s been proven that that puts carcinogens into the air. Sooner or later that stuff starts to affect you. We see it all throughout the field.”

The investment in Viega systems may cost more than traditional systems, but the payback is huge. “You have to look at it as an entire project,” he says, comparing the cost of labor to the cost of product. With MegaPress, for example, an installer can be done 30 to 90% quicker, saving on labor costs. “You save on the labor, and you get a better product.”

Here is a guide to Viega’s top press solutions.

What is ProPress Copper?

Viega ManaBloc and ProPress fittings used in a mechanical room. Photo courtesy of Sweenor Builders

Viega’s flagship begins with ProPress System, available in sizes of one-half-inch to four inches. This system for copper tubing (there’s also one for stainless steel, detailed below) can be used on things like potable water, heating and cooling glycol lines, and even compressed air.

ProPress has pipe fitting configurations approved for more applications than any other brand. Connections can be made wet or dry in seven seconds or less.

“Our fittings create a water- or air-tight permanent mechanical connection. On the smaller sizes it creates a hexagonal shape that both goes into the tubing and the fitting to give it mechanical strength,” Henkowski says. “On our larger sizes we utilize a 420 stainless steel grip ring, a PBT separator ring, and an EPDM sealing element. These fittings have the same strength capabilities as our smaller sizes.”

When using a press system the chance for leaks after installation is severely decreased—especially with Viega’s smart connect technology. “Even if you’re really good at it there’s always a chance for human error. But with ProPress, as long as you follow installation procedure, it does the same thing every single time.”

ProPress at a glance:

- For use on copper pipe in sizes ½” to 4″

- More than 400 fitting configurations

- More approvals than any other copper press fitting system

- Available with EPDM, FKM

Can be used with:

Water/Liquids

- Hot and cold potable water

- Rainwater and greywater

- Chilled water

- Hydronic heating water

- Steam (low-pressure and residential)

Fuels/Oils/Lubricants

- Ethanol

- Lube Oil

- Heating Fuel Oil

- Diesel Fuel

Gasses

- Compressed Air

- Nitrogen

- Carbon Dioxide

- Carbon Monoxide

- Argon

- Oxygen Hydrogen

- Vacuum

ProPress Stainless Steel

ProPress Stainless at a glance:

- For use with 316 stainless tubing

- More than 350 fitting configurations

- Approved for more than 800 applications

- Available with EPDM, FKM

Can be used with:

Water/Liquids

- Hot and cold potable water

- Rainwater and greywater

- Chilled water

- Hydronic heating water

- Treated water

- Reverse osmosis water

- Methyl ethyl ketone

- Isopropyl alcohol

- Nitric acid

- Phosphoric acid concentration

- Residential steam

Fuels/Oils/Lubricants

- Ethanol

Gasses

- Compressed air

- Nitrogen

- Carbon dioxide

- Argon

- Ammonia

- Oxygen

- Hydrogen

- Acetylene

- Vacuum

Special Media

- Methanol

- Latex paint

- Urea solution

- Caustic soda

- Acetone

What is MegaPress?

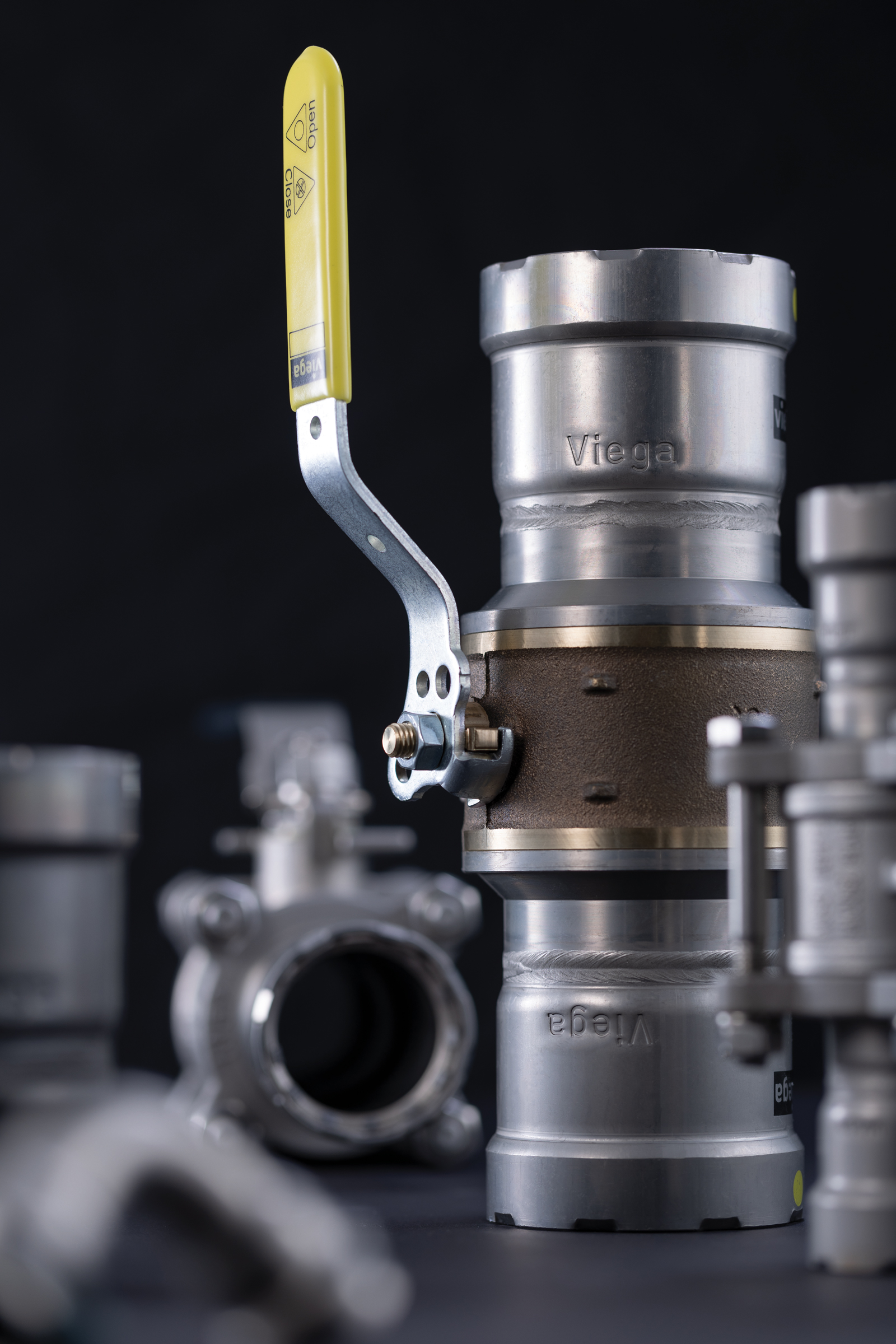

- Viega MegaPressG fittings. Photo courtesy of Viega

- Viega MegaPressG ball valve. Photo courtesy of Viega

The MegaPress system is available half-inch up to four inches, and every Viega MegaPress fitting has their Smart Connect® technology to help easily identify unpressed connections. It’s made for black iron and steel pipe and stainless steel pipe systems. It follows the same process as the large size ProPress with the grip ring, separator ring, and sealing elements. “We utilize the same connection method, but there are more applications for all these fittings as well as the piping method,” Henkowski says.

MegaPressG fittings, with an HNBR sealing element and designated with a yellow dot, are great for natural gas and fuel oil installations. Conversely, MegaPress fittings with EPDM sealing element and a green dot work well in heating and cooling applications and low pressure steam. “And then with our MegaPress stainless, you can use it for a lot of different, more corrosive media. This is more of an industrial type of product.”

What’s perhaps most efficient, Henkowski says, is that they utilize the same press tool as ProPress with just a simple swap of press jaws. “It’s really easy to move from one job to the next.”

Henkowski notes that, like all of Viega’s systems, MegaPress is durable.

“When you typically thread a pipe, which would be something you’d use in place of MegaPress or as a traditional system, you actually remove the wall thickness. You’re making the piping thinner than it was before. And you’re taking off that protective coating. When you do that it starts to deteriorate. If something hits it it’s the first spot to break. It can loosen up over time and fail. Whereas with MegaPress we’re doubling that wall thickness. We have a Schedule 40 pipe, and then we’re putting a Schedule 40 fitting on top of that and pressing it so it’s actually more durable. Not only is it faster and safer; it’s more durable than it was in the first place.”

MegaPress at a glance:

- For use with Schedule 10 through Schedule 40 and Schedule 80

- More than 200 configurations

- Approved for more applications than any other carbon steel press fitting system

- 50 to 90% installation cost savings compared to traditional methods

- HNBR sealing element approved for use in gas and fuel oil applications

- First fitting approved for connecting gas pipe up to 4 inches

- Nearly 150 configurations from half-inch to 4 inches

Can be used with:

Water/Liquids

- Chilled water

- Hydronic heating water

- Isopropyl alcohol

- Fire sprinkler steam

- Residential steam

Gasses

- Compressed air

- Nitrogen

- Carbon Dioxide

- Argon

- Oxygen

- Hydrogen

- Acetylene

- Vacuum

What is PureFlow?

Viega’s PEX system is called PureFlow, and it goes from one-half-inch to two inches. It uses the same technology as its other solutions but with a stainless steel ring that presses over the outside of the tubing, pressing down onto the fitting in a way that’s safer, more efficient, and more reliable.

PureFlow is also the only system in the industry that offers press transition fittings, so you can easily transition from PEX to copper in traditional branch and tee installations. For anyone looking to reduce the number of fittings (and potential for leak points) behind a wall, PureFlow includes the ManaBloc—giving each fixture in a home or building its own PEX tubing line and shutoff valve.

New Products

A new ProPress balancing valve also increases efficiency and has a lockable handle so no one can come in after you and change your balancing. New accessories for valves were also recently released.

The 316 ProPress Stainless Eco Tubing is among Viega’s latest offerings. The Eco Tubing comes with a thinner wall than its stainless tubing counterpart, so it can be used in place of copper and other systems while still being a strong, long-lasting system. It is approved for potable water applications, too.

“In commercial type projects where copper costs are shooting through the roof, we can bring them a stainless steel product that is more durable and still gives them the same capabilities of ProPress,” Henkowski says.