Story at a glance:

- An external insulation finishing system, or EIFS, is a type of non-load bearing building cladding system.

- EIFS was designed to be a cost-effective replacement for stucco and is ideal for both new construction projects and retrofits alike.

- The benefits of an EIFS include improved energy efficiency, effective moisture control, high durability, and weather resilience.

An external insulation finishing system, or EIFS, is a type of non-structural building cladding system that is used to both protect and insulate exterior walls. Originally developed as an alternative to traditional stucco, the EIFS is an effective and long-lasting means of improving both the thermal performance and aesthetic appearance of a building.

In this article we’ll cover the ins and outs of an EIFS and its components, explore benefits and disadvantages, discuss the differences between an EIFS and conventional stucco, and share a few EIFS maintenance tips.

What is EIFS?

An external insulation finishing system, or EIFS—also known as External Thermal Insulation Composite Systems (ETICS) and Exterior Wall Insulation (EWI) systems—is a category of non-load bearing building cladding system used to provide exterior walls with an insulated, finished, and water-resistant surface.

These integrated composite material systems are an extremely effective, efficient, and simple means of adding an additional layer of continuous insulation around a building’s exterior, making them ideal for use in both retrofit projects and new construction.

A Brief History of the EIFS

The EIFS originated in 1950s Europe following two significant technological advancements: the granting of the first patent for expanded polystyrene (EPS) insulation board and the development of the first synthetic water-based plaster. These earliest instances of EIFS were installed almost exclusively in Europe and were originally used as a means of both restoring the appearance and improving the thermal performance of old masonry walls.

It was not until the 1960s that the EIFS began to be marketed outside of Europe, with the EIFS becoming extremely popular in North America by the 1970s due to its superior insulating qualities and the cost advantages compared to traditional stucco.

Despite its popularity EIFS would go on to face international controversy and a slew of lawsuits in the late 1980s and 1990s after many EIFS-clad buildings began to develop problems relating to water damage and subsequent mold growth. Although it wasn’t any more prone to water infiltration than other exterior finishing systems, early EIFS did not possess sufficient water management features that would allow drainage of any water that did manage to penetrate the building’s exterior face.

The EIFS industry has consistently maintained that these problems were not the direct fault of the EIFS themselves, but the result of poor craftsmanship, improper installation, or bad architectural detailing around the perimeter of the EIFS. Contractors and other construction professionals have pointed out, however, that requiring EIFS be installed by highly skilled workers negates its status as a cost-effective replacement for stucco.

These controversies ultimately led to building codes mandating that drainage systems be installed for in conjunction with the EIFS on wood-frame buildings and additional on-site inspections be conducted to verify compliance. With these new standards in place the EIFS began to rise in popularity once more, with most wood-framed buildings built post-1997 making use of an EIFS.

EIFS produced after the year 2000 is typically free from the moisture-related problems that befell those manufactured prior to the turn of the century, as these newer systems feature an air/moisture barrier behind the foam insulation layer. When paired with an adequate drainage plane, this air/moisture barrier provides superior protection against water intrusion, greatly reducing the risk of water damage and mold growth.

Types of EIFS

EIFS is, for the most part, defined by the materials used in its composition and whether or not it features a drainage plane. Currently the EIFS Industry Members Association (EIMA) recognizes two types of EIFS—Class PB and Class PM—both of which are capable of supporting a drainage plane.

PB EIFS

As the most common type of EIFS used in the United States, the PB or polymer-based EIFS utilizes expanded polystyrene insulation adhered to a substrate material with fiberglass mesh embedded in a 1/16 to 3/32-inch base coat. Additional layers of mesh may be applied to strengthen the EIFS’ overall impact resistance.

PM EIFS

A PM or polymer-modified EIFS, on the other hand, uses extruded polystyrene (XEPS) insulation and a thick, cementitious base coat—typically between 3/16 and ¼-inch thick—that is applied over fiberglass reinforcing mesh mechanically attached to the sheathing via screws and plates.

The PM EIFS is still in use today but is much less common than the PB EIFS.

Anatomy of an EIFS

Photo courtesy of ERA Architects

While there is some variation regarding the exact components used to construct an EIFS, their anatomy can generally be described as consisting of the following:

- Waterproofing membrane. An EIFS may include an optional waterproofing membrane or water-resistive barrier (WRB) that is installed directly over the substrate material; WRBs are often required by building codes if the EIFS is being installed over wood-frame construction to preemptively avoid water damage.

- Drainage plane. If an EIFS features a drainage plane it will be positioned between the WRB and insulation board; most drainage planes are made by applying vertical ribbons of adhesive over the WRB.

- Insulation board. A EIFS manufactured today typically includes an insulation board made from EPS insulation (though some utilize mineral wool insulation) that is secured to the substrate using adhesive or mechanically via screws and plates.

- Reinforcing mesh. An EIFS features a layer (or layers) of fiberglass mesh embedded in the base coat; the mesh serves to reinforce the wall system, with additional layers providing greater impact resistance.

- Base coat. A water-resistant base coat is applied over top of the insulation as a means of protecting it from the weather.

- Finish coat. An acrylic co-polymer finish coat is then applied over the primed base coat to provide a decorative, crack-resistant, and durable finish; a contemporary EIFS may be finished in a wide variety of colors and textures.

Benefits of EIFS

Installing EIFS provides a range of beneficial qualities that makes them an ideal product for new construction and retrofit projects alike. It should be noted, however, that these benefits depend entirely on whether the EIFS is properly installed by experienced professionals.

Energy Efficiency

Energy efficiency is perhaps the most important benefit offered by an EIFS and is a characteristic that is integral to their design. An EIFS typically possesses an R-value between 4 and 5.6 per inch and helps buildings reduce their overall energy use by approximately 45% over a 12-month period, according to a 2022 Better Buildings Federal (North America) Awards program.

On average an EIFS is approximately 84% more energy-efficient than comparable cladding options, outperforming stucco, brick, stone, and more.

Moisture Control

As long as it features a WRB, drainage channel, and is installed properly, EIFS offers excellent moisture control. Recent research from the Oak Ridge National Laboratory states the EIFS is “the best performance cladding” with regard to moisture and thermal control compared to fiber cement, stucco, and brick siding.

Durability & Resiliency

EIFS is also extremely durable and resilient towards weathering, in large part thanks to the use of acrylic binders, which help prevent yellowing, chalking, and fading. Unlike stucco and many other exterior finishing systems, this allows an EIFS to maintain its original appearance for a long time. An EIFS is also designed to be flexible, making it less likely to develop cracks as a result of temperature changes or seismic activity. Certain EIFS products have even passed the rigorous Miami-Dade County Hurricane Test, sustaining no adverse impacts from hurricane-style weather.

As long as EIFS are properly installed and maintained, they should last the lifetime of the building itself—in fact, many of the original EIFS manufactured in the 1960s are still in use today, giving EIFS an estimated lifespan of 60+ years.

Low Maintenance

Once installed an EIFS is very easy to maintain, typically only requiring periodic cleaning with low pressure cool water, a non-acidic cleaner, and soft-bristled brush. Choosing the right colors and performance-enhancing additives for the EIFS’ finish can help reduce the need for maintenance even further, limiting the need for frequent resurfacing or recoating.

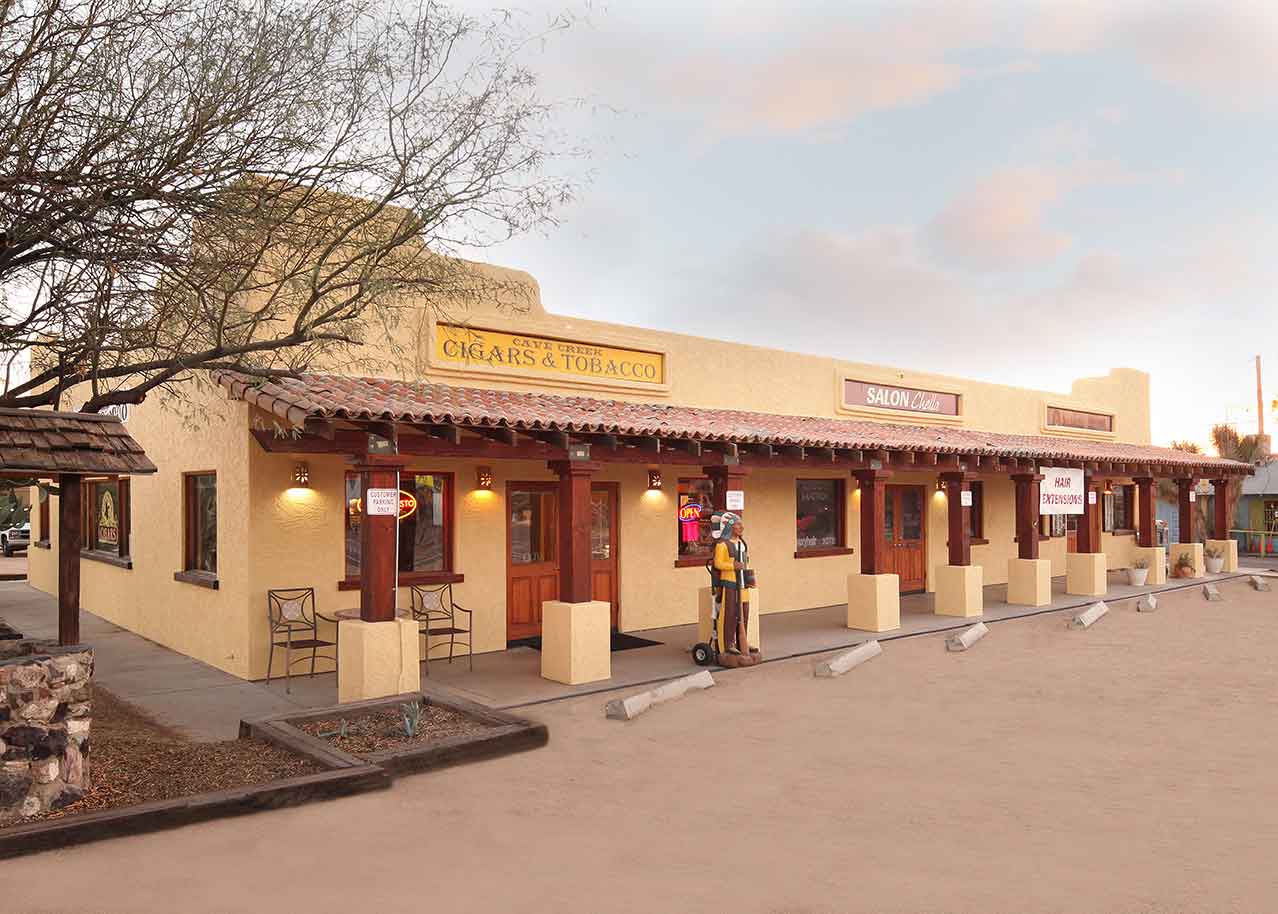

Versatility

Because EIFS may be fashioned into virtually any shape or design and support a wide range of finish colors, patterns, and textures, it is extremely versatile and capable of complementing a variety of architectural styles. Skilled EIFS applicators can take advantage of this extreme versatility and design malleability to create a wide variety of exterior architectural elements—like columns, pillars, cornerstones, cornices, arches, and more—that otherwise might be cost prohibitive using conventional construction practices.

Disadvantages of an EIFS

There are very few outright disadvantages associated with EIFS. Problems can, however, arise if it is poorly or improperly installed.

Water Infiltration & Moisture Buildup

One of the most common problems stemming from a poorly installed EIFS is water infiltration and moisture buildup, both of which can result in mildew/mold growth and damage to the substrate material. This is especially true if the EIFS is installed over wood substrate, as prolonged exposure to moisture may lead to rotting and structural failure.

Water is particularly destructive because of how effective the EIFS is at preventing air infiltration, as this quality makes it extremely difficult for the EIFS’ innermost layers to dry out. In the event that an EIFS has been significantly or extensively damaged by water infiltration, it can necessitate replacement of the entire system altogether.

Insect Damage

Aside from leading to mold growth, the buildup of moisture behind an EIFS can also increase the chances of pest infestation. To make matters worse, the insulating foam panels inside an EIFS provide an ideal environment for wood-eating insects like termites and carpenter ants, both of which can cause serious structural damage if left untreated.

EIFS vs Traditional Stucco

EIFS and stucco look very similar but possess a few key differences. Photo courtesy of APV Engineered Coatings

Now that we’ve a better understanding of the EIFS, let’s take a moment to talk about how it differs from traditional stucco.

Affordability

Because stucco is made from common, easily sourced materials, it is typically an affordable means of protecting an exterior wall from the elements. An EIFS is often the more expensive option of the two, as the installation process is time consuming and requires highly skilled, experienced contractors.

In the long term, though, an EIFS is considered to be more cost-effective than stucco, as it helps improve energy efficiency and greatly reduces a building’s utility bills.

Installation

External insulating finishing systems also differ from stucco when it comes to their installation methods, though both require the hiring of skilled, experienced contractors to ensure the process is carried out properly.

An EIFS consists of an air-and-water resistant barrier applied to the substrate, upon which sheets of insulation are attached using adhesive or mechanical means. This layer of insulation is protected by a layer of reinforced fiberglass mesh embedded in an acrylic base coat, which is then covered by a final layer of acrylic finish. EIFS installation is a fairly involved process and can be somewhat time consuming due to the amount of components used.

Applying stucco is a relatively quick and straightforward—albeit labor-intensive—process. Stucco must first be mixed using a combination of Portland cement, lime, sand, water, polymers, and fibers, with different amounts of certain ingredients altering the stucco’s characteristics (adding more fiber, for example, increases its strength).

Once mixed, stucco is then applied in multiple coats to achieve the desired thickness, depending on the trim accessories being used. Stucco is most commonly applied in a total of three coats overtop an expanded metal lath, after which it may be coated with an acrylic finish to minimize moisture absorption and cracking.

Weight & Flexibility

An EIFS is, on average, 80% lighter than stucco (which typically weighs approximately 10 lbs/sq. ft) and so does not put as much strain on the substrate layer, allowing for easy, non-invasive installation on almost any surface, even wood—stucco, on the other hand, is typically only applied over the surface of masonry walls.

An EIFS is also designed to be much more flexible than traditional stucco and is more resistant to changes in both temperature and humidity, reducing both the acrylic base coat and finish layers’ risk of cracking. Because stucco is made primarily from natural materials that expand and shrink in response to moisture and temperature changes, cracking is extremely common.

Insulative Capacity

Generally speaking traditional stucco is not applied with the intent of serving as a thermal insulator and so does very little to help prevent heat loss or gain. Most stucco only has an R-value of about .20, which is extremely low. An EIFS, however, is designed to improve a building’s overall insulative capacity and typically possesses an R-value between 4 and 5.6 per inch.

Warranties

Due to the nature of its manufacturing and application, stucco is not capable of being protected under warranty, meaning the building owner will have to foot the bill for any repairs or replacement, should they become necessary. An EIFS, on the other hand, is typically covered under warranty and therefore provides the building owner with more peace of mind.

EIFS Maintenance Tips

Once it’s been properly installed, an EIFS is fairly easy to take care of and is relatively low maintenance, especially when compared to the traditional stucco finishing systems they are meant to replace. Exact care instructions will vary slightly from one EIFS to another, but the following tips are more-or-less universal when it comes to maintaining a building’s EIFS.

Periodic Cleaning

Like any exterior cladding EIFS is exposed to the elements and requires cleaning once in a while to remove any dirt, algae, or mildew that might accumulate on its surface.

In most cases EIFS may be cleaned with a mild cleaning detergent, low-pressure cool water, and a soft-bristled brush. It is generally recommended that the EIFS be cleaned thoroughly at least once every five years, but more frequent cleaning may be necessary depending on local factors. Cleaning is also necessary before resurfacing or recoating an EIFS in order to ensure proper adhesion.

Check for Cracks & Repair Damages Promptly

An EIFS is designed to be much more flexible and resistant to cracking than stucco, brick, and concrete exteriors, but they can develop small cracks, chips, and spalls over time as a result of either structural movement or water infiltration. These surface-level defects typically do not penetrate beyond the base coat—and as such will not jeopardize the integrity of the reinforcing mesh—but they do provide crevices for dirt, grime, and other contaminants to accumulate in, and may lead to more expensive problems if left unchecked.

Regularly inspecting the surface of an EIFS for cracks and other minor defects—and promptly repairing any that you find—is the best way to ensure its longevity. A damaged EIFS can often be repaired by cutting out the affected area and replacing it, rather than requiring the entire system be replaced.

To ensure repairs are done correctly, it is recommended that you either use the the Association of Wall and Ceiling Industry’s national database of contractors—all of whom will have passed the “EIFS Doing it Right” course—or contact your local EIFS distributor, as they should be able to assist in locating appropriately-qualified contractors.

Recoating & Resurfacing

While not strictly necessary it is highly likely that at some point during an EIFS’ operational lifespan the building owner will want to repaint or change the color of the EIFS. In these instances the EIMA recommends purchasing high-grade acrylic or elastomeric paint from a reputable EIFS manufacturer.

Before recoating the EIFS, take care to clean the surface of any contaminants and ensure that all cracks or damages are repaired.