Bentley Mills incorporates Type 6.6 Nylon into its products for its resiliency, stain resistance, fade resistance, and color fastness. Photo courtesy of Bentley Mills

It’s not easy manufacturing in California, where companies are held to higher standards and regulations are among the most stringent in the US. “California has never backed down from their environmental initiatives, and we follow in those same footsteps,” says David Turkes, director of sustainability for Bentley Mills, a luxury sustainable flooring brand since 1979.

Bentley Mills was the first manufacturing facility in the US to be LEED-certified, and their carpet products continue to be produced in California, earning them a number of certifications and green labels. Today they have new products in a range of colors across commercial projects, from the new “non-solid solid” Color Core to the multi-faceted and textured Off the Chain.

“Sustainability has been an integral part of who we are as a company since day one,” Turkes says. “Being able to identify the needs of the client, create a durable and long-lasting product, and find ways to mitigate and minimize the effects of manufacturing is something we strive for on a daily basis. Whether it’s participating in the creation of new standards, identifying new equipment and technologies, or implementing strategic changes in our processes, these are just some of the ways we look at all pieces of the puzzle.”

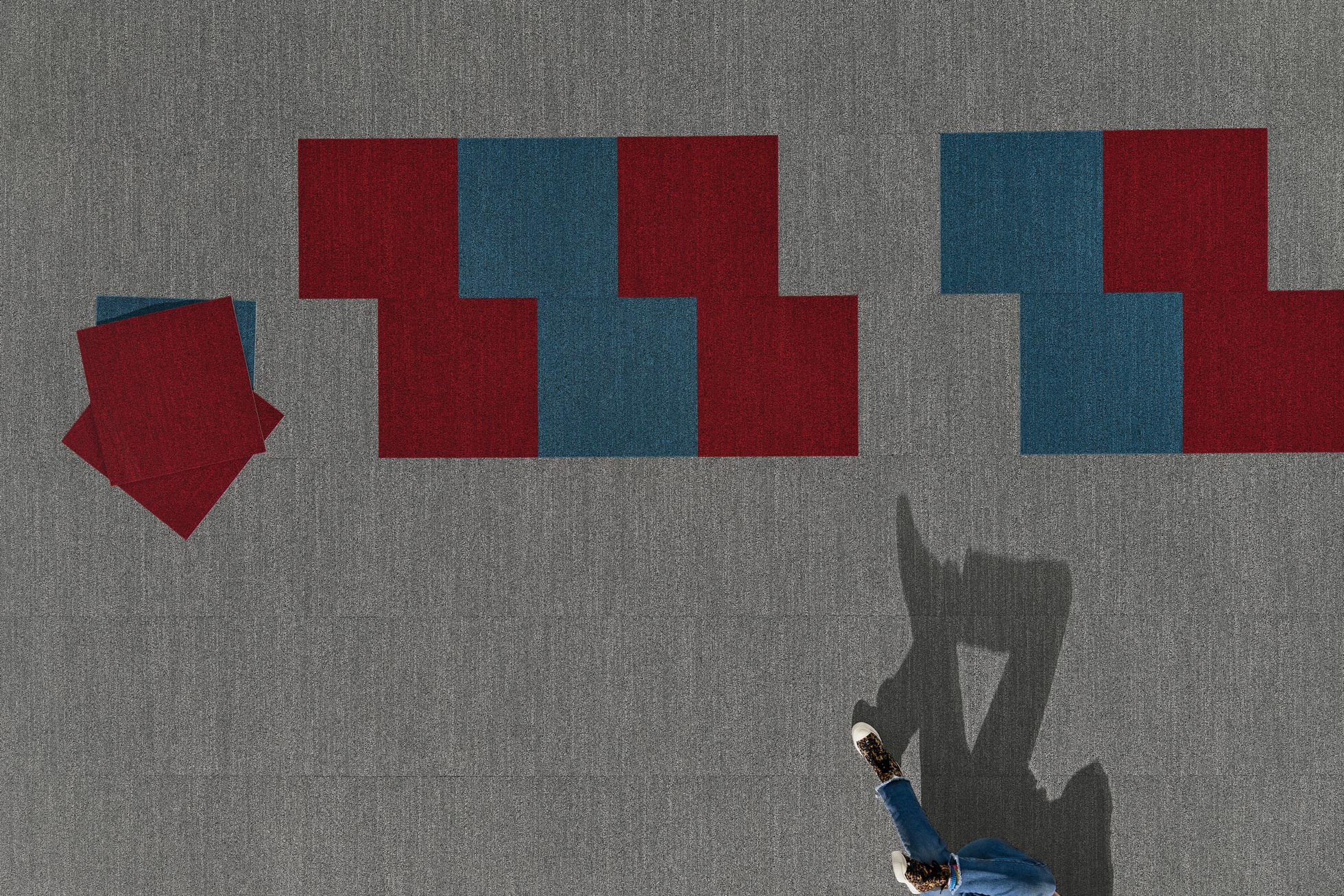

Color Core’s contrasting but complementary yarn components give specifiers color without distracting from other elements in a space. Photo courtesy of Bentley Mills

What’s New in Sustainable Flooring?

One of Bentley’s newest products is Color Core, a “non-solid solid” available in broadloom or tile that’s the kind of offering every project needs, according to Ginger Gilbert, vice president of product design and development at Bentley Mills. Color Core’s contrasting but complementary yarn components in traditional reds, blues, browns, and grays subtly expose a more complex identity as they emerge and retreat throughout the carpet, giving specifiers color and interest without distracting from other elements in a space.

“When you’re dealing with color you need to look at it from an architect’s standpoint. What are they doing with their upholstery or graphics on the walls? If they are going to use purple they’re going to use it on the wall, so we’re going to use it very sparingly or as a grayed out version,” Gilbert says.

Gilbert also points to studies that show spaces with nicer finishes and flooring tend to be more cared for by the people who use them. “Keeping that in mind, people do need to use flooring to define the space. There are so many things going on right now with acoustics, lighting, different ceiling elements, so having the carpet and the ceiling really there to capture the noise so all these spaces can have different functions if they need to is important,” she says. “As far as aesthetics, we’ll always have patterns, but we will continue to do what Bentley’s always done and have these really beautiful, luxurious textures that create depth and visual warmth.”

She says Color Core came about because people were asking for accents; they wanted to do areas of color, but they didn’t want pattern and color to compete. They wanted a non-solid solid that could go in areas accompanied by pops of color. “We’re helping them define space with color.” Color Core also harkens back to an old-school flat weave style that’s back in demand. “Everybody wants that look right now,” Gilbert says.

Off the Chain—with its more textural, almost sweater-like feel—is another new environmentally friendly Bentley product. “Off the Chain is based on embroidery and chain stitching,” Gilbert says. “We were looking at knitting and work done by hand. We wanted to create a feel that was fairly low in ounce weight but that also brought a feeling of warmth into a space.” She says that’s especially important considering how more buildings are dominated by glass but also living walls. “Plants are coming back into spaces,” she says. “They’re a design element we need to work with, creating more textures versus patterns where people are trying to mimic the outside. We’re supporting the outside in bringing that texture and warmth to a space.”

How Can Flooring Really be Sustainable?

Fiber is the most important element of Bentley’s products. “We are big believers in Type 6.6 Nylon,” Gilbert says. What makes this fiber so special? Resiliency, stain resistance, fade resistance, and color fastness, to name a few things.

Bentley partnered with Universal Fibers to create the 6.6 nylon fiber that makes Color Core sustainable. “We found a fiber we could use to really make a difference in all of our products,” Gilbert says. “A lot of times you create a fiber and it can only be used on a certain machine, but that’s what’s so great about Color Core. The fiber used there we can use anywhere. It helps us get products to the right price point while maintaining the high performance.”

“We wanted to do something different with the fiber and create a one-fiber product that had personality,” Gilbert says. It’s this complexity that allows Color Core to easily blend with other products while still being bold. Photo courtesy of Bentley Mills

People don’t often think of Bentley when they think of value products, Gilbert says, but Color Core allows them to stay true to their mission of luxury while offering an affordable solution. “We’re able to keep what people love about Bentley—the aesthetic, the performance, the quality,” she says. “We didn’t want to sacrifice that because I know a lot of people who specify Bentley say they’ve had it for years, and that’s really important. In the end the carpet has to stay on the floor for a while to not be a nuisance to the world.”

How Bentley uses the Type 6.6 Nylon fiber is another thing, and Gilbert says the manufacturing process is almost militant. At first that might frustrate designers, she says, but ultimately it’s fulfilling. “Maybe it’s because we’re in California. It’s a different mentality. If something doesn’t meet our standards, we go back to the drawing board. We’re going to find a way to make it work,” she says of the three-person in-house design team. “We’re putting out a product that really performs, and we’re using components and machines differently now. In some cases it’s because that’s where the industry is taking us. In other cases, that’s what we need to do.”

Turkes says California’s manufacturing sector is held to some of, if not the most stringent regulations in the world. “We’ve seen how changes have made positive impacts—whether it be in air quality, water quality, resource conservation, energy consumption and efficiency, or infrastructure changes,” he says. “As we’ve been operating in this state since 1979, we’ve adapted and grown with the state in these goals and aspirations, and we continue to meet and exceed each regulatory standard that has been created.”

This way of thinking is, slowly but surely, part of an overall shift in society, Turkes says. “Whether it’s through new state legislation opportunities or the thought process regarding material selection, we’ve been part of creating that shift in how products are constructed, how they can be best suited to meet institutional or individual requirements, and ensuring scientific backed methodologies continue to drive positive change for all involved stakeholders in our manufacturing process.”

How Does Bentley Approach Design?

Bentley’s tight-knit design department—three people in a company of nearly 400—is constantly collaborating and looking for ways to innovate. “We have a thing called ‘Observations,’” Gilbert says. “I can’t stand the word trends, so we call it observations.” On any given day Gilbert and another designer may be on the phone well into the evening talking about things that inspire them—a color, a fabric, something someone saw in nature—and assigning them to buckets like “fashion” or “nature” so they can review the ideas as a group later. “We do that instead of planning meetings where it’s like, ‘Everybody be creative right now,’ which is not possible for creative people,” she says. Instead, once they have some great ideas, they print several of the best images and leave them around to gather feedback. “We collectively start eliminating things we don’t like or that we’ve seen before. Then we have a meeting, and the three of us will sit down and talk about the patterns we keep gravitating to. If we’re all three gravitating with that collective gut feeling of ‘This is the right thing to do,’ that drives us,” Gilbert says. It’s a process that allows everyone on the team to have ownership. “Our culture here is really a collaborative culture. We’re open to every idea.”