Story at a glance:

- Urbahn Architects brought a new innovation hub to life on one New York college campus.

- The design, engineering, and construction teams worked together to achieve LEED Gold on a tight budget.

- The final building envelope and mechanical systems designs resulted in an energy cost savings of 28%.

Just 90 minutes from New York City, students and researchers toil away, working in 3D design, 3D printing, and more. It’s part of the work happening inside the new Engineering Innovation Hub (EIH) at the State University of New York at New Paltz, a highly selective college of about 8,000 undergraduate and graduate students. The project itself is a standout example of LEED Gold design.

The new EIH was designed by Urbahn Architects, who worked with engineering and construction teams to achieve LEED Gold on a limited budget.

“An efficient, sustainable building can be designed within the confines of a limited budget,” Urbahn Architects’ Senior Associate Nandini Sengupta says in a press release. “Bring in seasoned design consultants early in the conceptual phase and perform continuous energy modeling starting in the conceptual design phase.”

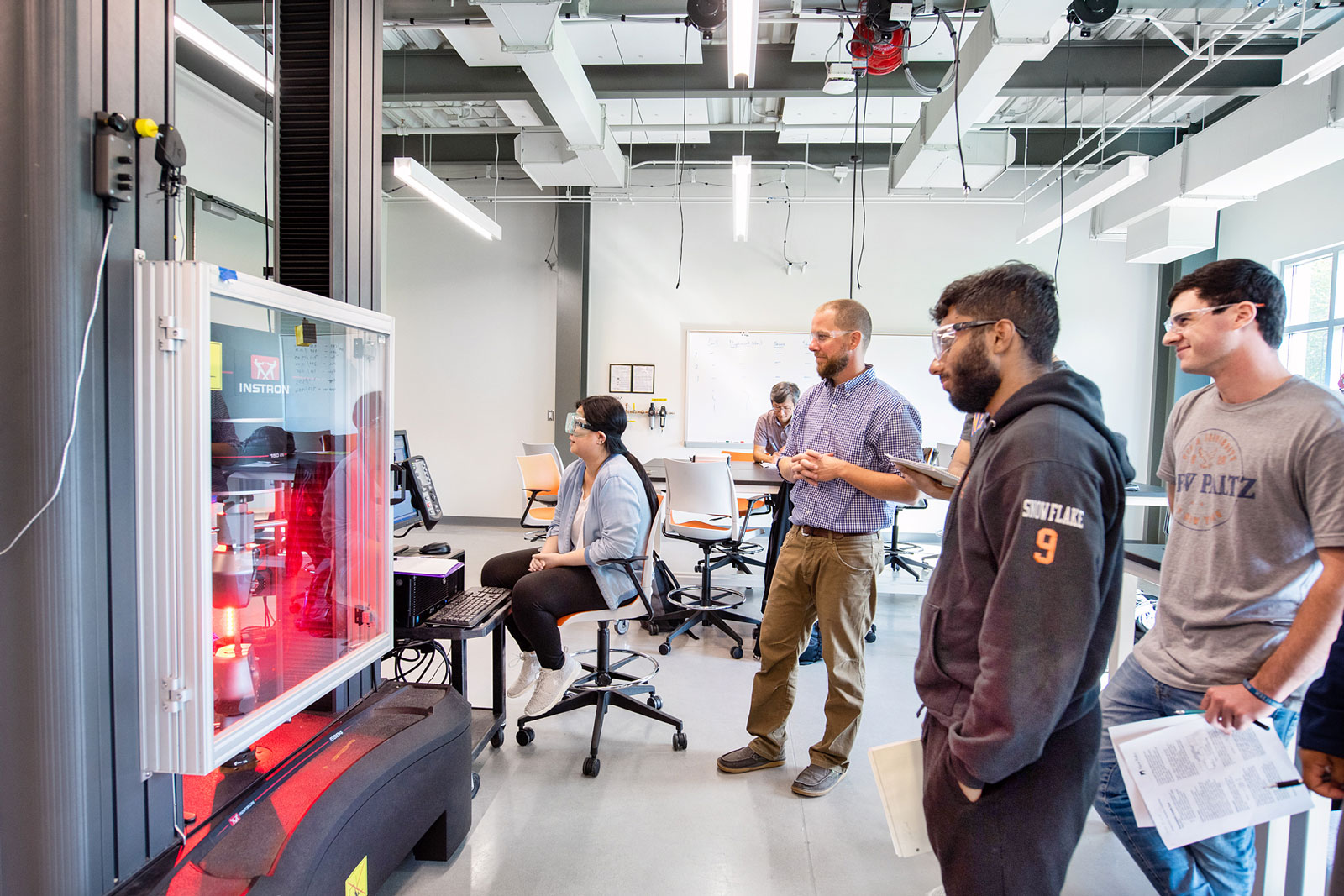

Inside the Innovation Hub at SUNY New Paltz. Photo by Ola Wilk

Sengupta said the client, design team, construction manager, and contractor were methodical from the beginning to enable the building to achieve the rating. The final building envelope and mechanical systems designs resulted in an energy cost savings of 28%.

“Relying on our team’s expertise in LEED certification procedures and the Lean Construction method, we have delivered a highly sustainable and energy-efficient facility where engineering students can excel for years to come,” Michael Davies, project manager for PC Construction, says in a press release. More than 86% of the project’s construction waste was diverted from landfills.

Photo courtesy of State University of New York at New Paltz

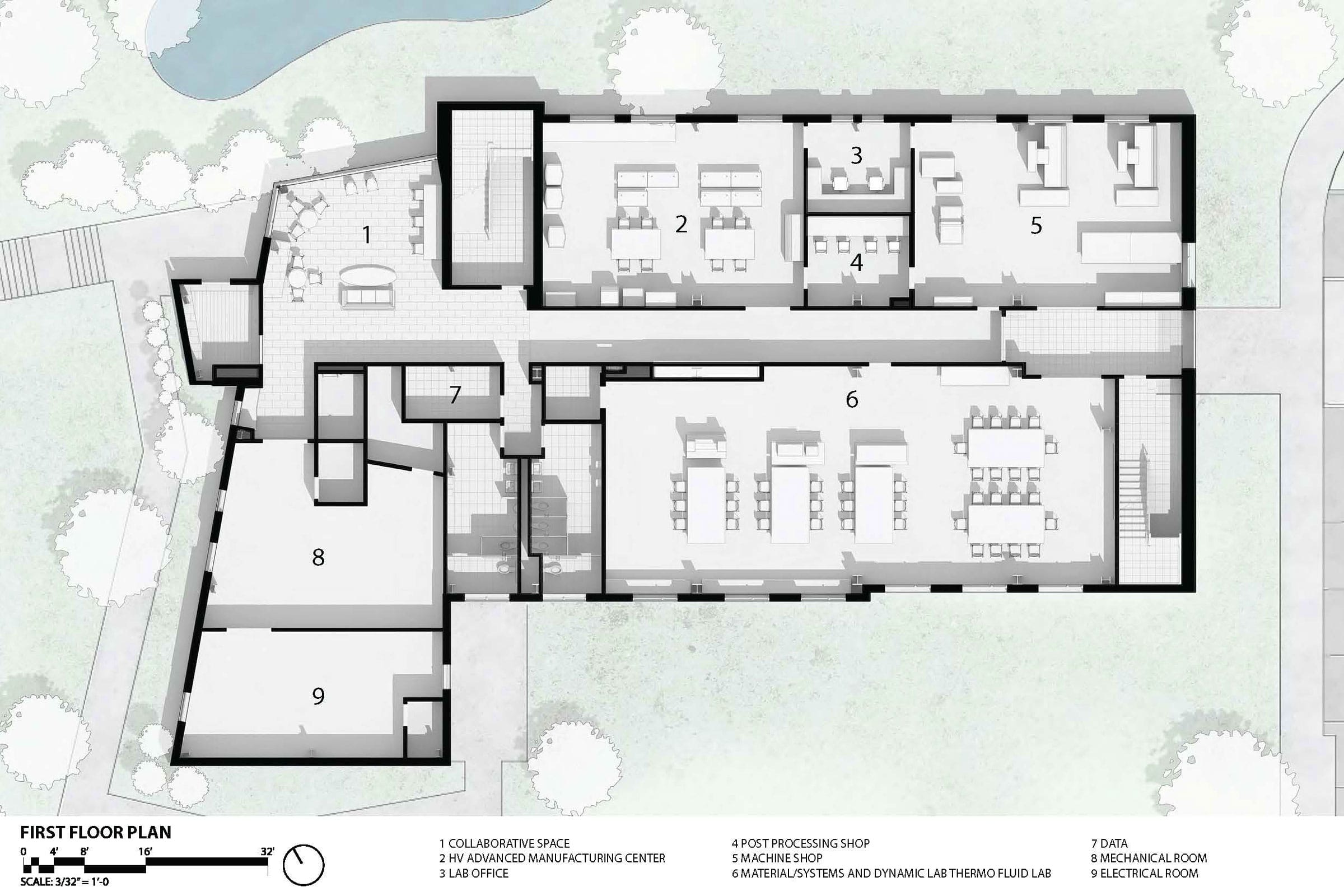

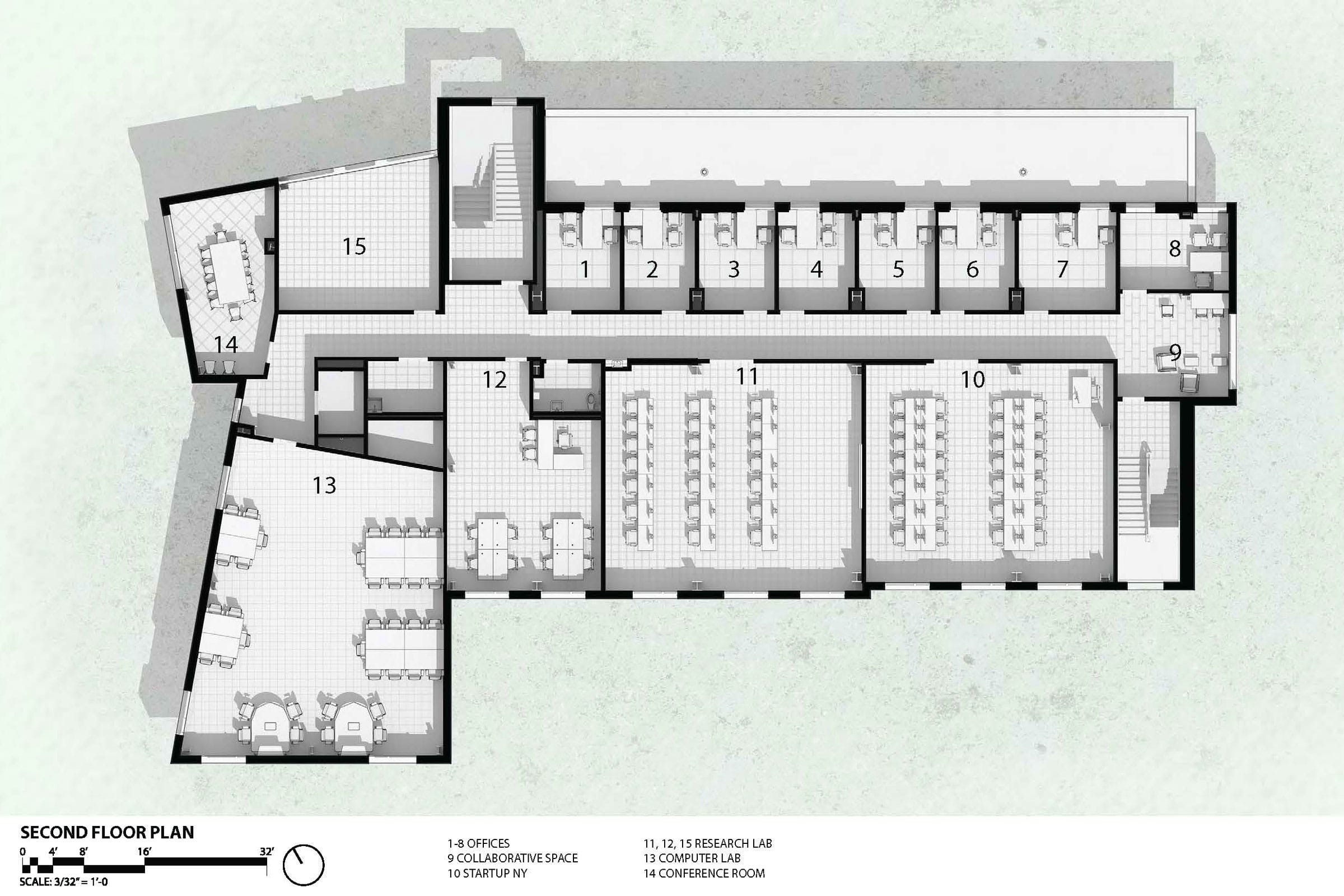

The now finished innovation center is two stories, housing the relatively new and popular—it’s seen rapid enrollment growth since its 2014 launch—bachelor’s degree program in mechanical engineering. The program includes innovative teaching and research lab spaces as well as the Hudson Valley Additive Manufacturing Center (HVAMC) at SUNY New Paltz.

Urbahn designed the EIH to allow for potential expansion of the building to accommodate programming and support collaboration between the college and local industry.

Photo courtesy of State University of New York at New Paltz

The design of a 31,200-square foot landscaped site contributes to the project’s sustainability. The project team addressed the LEED category of Sustainable Sites and Water Efficiency in several ways. The entire building site was formerly covered by a parking lot, and the new site plan maximized the open green area surrounding the building footprint.

“Slab-on-grade foundation design eliminated the need for extensive and costly rock excavation that is typical for construction projects in the Catskill Mountains region,” Sengupta says.

Landscaped bioswales direct rainwater into a 45-foot long retention pond that is provided with a weir and overflow gate to control discharge. Groundwater under the building footprint is also drawn into the pond through underground perforated pipe, preventing a rise in hydrostatic pressure that could potentially drive moisture into the building. Large boulders recovered from the site during excavation were reused around the bioswale to provide landscape interest. The bioswale has been planted with native evergreen shrubs, eco mix seed, and grasses.

LEED points were also awarded for several features of the building and its location. The building’s roof is a white reflective TPO (thermoplastic polyolefin) membrane system, with added insulation to improve the R-value. This composition reduces the heat island effect by providing a high solar reflectance index. The building is close to public transportation and provides bike storage.

Urbahn placed particular emphasis on maximizing daylighting and views throughout the building without compromising energy efficiency. “EIH’s ground floor lobby is wrapped in a glass storefront and glazed curtain wall systems to allow natural light into the interiors,” says Urbahn’s Project Manager Arielle Siegel Lapp in a press release. “Window headers are nine feet above the floor so light can penetrate deep into interior spaces. Our team analyzed several glazing options to maximize the energy efficiency of the exterior walls and ultimately designed window assemblies using double glazed low-E glass that provide ideal comfort levels, daylighting, and views while utilizing less than 30% of the exterior wall surface.”

Lighting is provided by high efficiency LED fixtures, some featuring a ring-like curvilinear configuration provided with light sensor controls. As the building fills with natural light from high windows during the day, light fixtures automatically shut off to conserve energy and turn on again as lighting conditions change.

Urbahn Architects designed the 1,900-square-foot teaching lab to invoke an industrial aesthetic, including exposed ceilings and structural elements and polished-concrete floors. Photo by Ola Wilk

Sengupta says the building’s architectural highlight, though, is its cubic form that perches over the entrance plaza.

“The textured, dark gray cube, with a luminous, bright red metal soffit above the entrance and a backdrop of lighter forms, announces the building as an important presence on the campus. It relates to neighboring buildings and opens up views to a quad, diagonally opposite to it.”

The exterior walls feature an ultra high-performance rain-screen system with high-performance concrete panels in light and dark gray. The light gray portions have smooth appearance, while the dark gray sections feature textured panels. The rainscreen has a stud backup.

Project Credits

Project Name: SUNY New Paltz Engineering Innovation Hub

Location: New Paltz, NY

Completion: Winter 2019

Size: 19,500 square feet

Cost: $13.5 million

Architect: Urbahn Architects

Contractor: PC Construction

Mechanical & Electrical Engineer: Vanderweil Engineers

Plumbing Engineer: CSA Group

Structural Engineer: LERA Consulting Structural Engineers

LEED Consultant: YR&G

Civil Engineer: BET Engineering Consultants

Landscape Designer: Edgewater Design

Lighting Designer: Lumen Architecture

Courtesy of Urbahn Architects

Courtesy of Urbahn Architects