Story at a glance:

- ISI Building Products’ Dario Lamberti discusses common moisture barrier issues and how to address them.

- You can protect your investment from the ground up with a high-performance under-slab vapor barrier system.

Protecting the concrete slab and building interior from moisture sources below starts from the ground up. Below slab water vapor remediation after-the-fact is a complicated and costly fix. The small, upfront savings when choosing a minimal protection moisture barrier can be appealing, but the result often turns into a long-term problem.

Proper planning and design will avert these potential headaches and expenses. Choosing the correct below slab water vapor protection is imperative to your finished floor and overall health and safety.

Proper selection and installation of a high-quality under-slab moisture barrier will result in a successful finished flooring system and provide you with long-term security and comfort.

What to Look for When Choosing a Below Slab Vapor Barrier

Moisture control is critical for the longevity of flooring assemblies, like this gym floor. Photo courtesy of ISI Building Products

What should you look for when choosing a below slab vapor barrier? To start, allow me as an expert from ISI Building Products, a leader in building materials innovation, to summarize a few moisture sources below the concrete slab. I will also share how those moisture sources can affect the finished floor and indoor air quality.

As the building envelope is typically enclosed with the HVAC system active, relative humidity below the slab will near 100%. In search of equilibrium, water vapor is able to diffuse through porous concrete, raising the pH and alkalinity of the slab. High pH and alkalinity at the flooring adhesive to slab interface can compromise the adhesion of the costly finished flooring system.

High pH and alkalinity at the flooring adhesive to slab interface can compromise the adhesion of the costly finished flooring system.

Furthermore, water vapor diffusing through an unprotected concrete slab can cause high relative humidity, mold, mildew, and degradation to the concrete slab and its components.

Other Causes for Moisture-Related Flooring

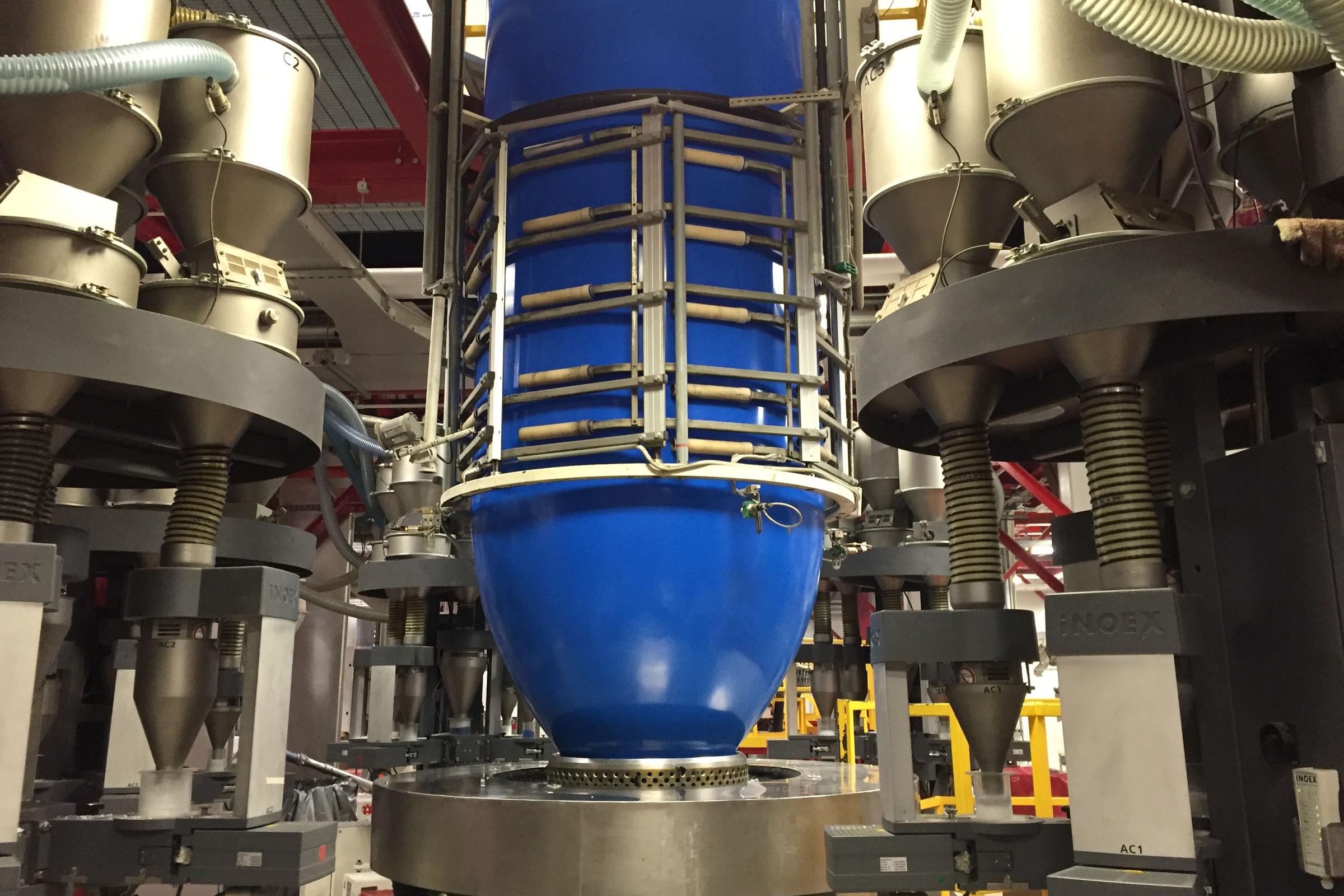

Co-extrusion vapor barrier during the manufacturing process. Photo courtesy of ISI Building Products

Other causes for moisture related flooring and IAQ issues relate to concrete slab placement and drying time.

Historically slabs were placed directly over a layer of sand with the idea to protect the polyethylene sheeting from damage during concrete placement and provide a means for bleed water to exit freshly placed concrete. The problem with this method is that while the sand layer does absorb excess water, the water gets trapped once it reaches the layer of polyethylene sheeting.

Similar to water vapor diffusion from the soil, once the building is enclosed and RH below the slab seeks equilibrium, the trapped bleed water has nowhere to go but up. Often the flooring system is prematurely allowed to be placed as the water within the sand layer goes undetected.

In the majority of the cases it is recommended to place the concrete slab directly onto the under-slab vapor barrier.

Differences Between a Vapor Barrier and Vapor Retarder

ISI Building Products’ Viper II 15 Mil vapor barrier ready for concrete pour. Photo courtesy of ISI Building Products

A foundational step when selecting a vapor barrier is defining the difference between a vapor retarder and a vapor barrier. The industry recognizes a vapor retarder as having a water vapor permeance rating between 0.1 perms and greater than 0.01 perms. Vapor barrier materials are considered to have a water vapor permeance rating below 0.01 perms.

For product comparison purposes, perm results are often reported as grains/(ft2*hr*in Hg). When evaluating products these terms and performance results will come in to play and can be found by requesting a data sheet from the manufacturer.

High-Performance Vapor Retarders and Barriers

The highest quality vapor barriers begin with virgin resin containing no recycled content. Photo courtesy of ISI Building Products

With advancements in plastic film manufacturing, higher performing materials are becoming the norm. It is important to look for moisture barrier products manufactured from 100% virgin resin. They are also typically manufactured in a multi-layer or co-extruded fashion. Co-extruded films are in high demand as they incorporate the best properties of different resins and link them all together into one film structure.

Given these innovative approaches to plastic film, specifiers should note thickness does not always directly correlate to performance. Less robust material like clear or black polyethylene sheeting, also known as visqueen, have been used as a minimal approach to protecting against the aforementioned moisture related issues. These types of products are typically manufactured from high levels of recycled content. The concern with these products is long-term effectiveness and lack of performance in areas such as strength and water vapor resistance.

High-performance vapor retarders and barriers are commonly available in 8-mil, 10-mil, 15-mil and 20-mil thicknesses. As mentioned, increased thickness does not always translate into better performance. Avoid single extruded products made from recycled content. For example, a 10-mil single layer extruded film made from recycled content will not carry near the performance of a thinner 8-mil co-extruded film manufactured from virgin resin. When evaluating vapor retarder and barrier products, it is key to make sure they are made from virgin resin and are co-extruded films.

Industry Standards to Know

Vapor barriers should be overlapped at the seams a minimum of 6 inches and sealed with a manufacturer approved tape. Photo courtesy of ISI Building Products

Industry organizations like the American Concrete Institute and the American Society for Testing and Materials have produced specific guidelines and testing standards for under-slab water vapor retarders and barriers.

For example, ASTM E 1745 (Standard Specification for Plastic Water Vapor Retarders Used in Contact with Soil or Granular Fill under Concrete Slabs) is a testing standard used for determining a product’s performance. ASTM E 1745 classifies materials as A, B or C based on the products puncture resistance, tensile strength and water vapor permeance.

Class A vapor retarders and barriers carry the highest puncture resistance and tensile strength, with Class C being on the lower end of the scale. The water vapor permeance requirement is currently set at 0.1 perms for all three classifications making the separating factors puncture resistance and tensile strength.

In addition to strength and water vapor resistance, materials should also be tested for long-term stability and performance. Such tests include:

- Sustainable water vapor permeance after wetting, drying, and soaking

- Permeance after heat conditioning

- Permeance after low temperature conditioning, and

- Permeance after soil organism exposure.

These accelerated aging tests shed light on a vapor barrier’s ability to perform for the long term. It is important to note most mono-extrusion films made out of recycled content, like polyethylene sheeting, do not typically pass the Class C rating.

As a best practice select products meeting the ASTM E 1745 Class A requirements. To take it one step further, ASTM E 1745 Class A vapor barriers (products with less than 0.01 perms) are the best approach to protecting your concrete slab and components, moisture sensitive floor and IAQ from moisture sources below.

How to Install Under-Slab Vapor Retarders and Barriers

Installation details, such as slab/footing junctures, are key to a quality install. Photo courtesy of ISI Building Products

Once evaluation and selection of a proper under-slab vapor retarder or barrier is complete, efforts should turn to proper installation.

ASTM has created a standard specific to the selection, design, installation and inspection of under-slab vapor retarders and barriers. ASTM E 1643 is the “Standard Practice for Selection, Design, Installation, and Inspection of Water Vapor Retarders Used in Contact with Earth or Granular Fill Under Concrete Slabs.” ISI Building Products’ Viper Vapor Barrier installation guides are based on ASTM E 1643.

The basic components of installing an under-slab vapor retarder and barrier are as follows:

- Be sure to select an appropriate sub-base material, taking into consideration the project requirements and the vapor retarder or barrier being installed. Properly level and compact the sub-base material to minimize risk of punctures.

- Create a monolithic membrane between the surface of the slab and moisture sources below the slab as well as at the slab perimeter. In other words, make a vapor barrier “bathtub” for the concrete.

- Roll out vapor barrier with the longest dimension parallel with the direction of the concrete pour. Face overlaps away from the concrete pour when possible.

- Extend vapor barrier over footings and seal to foundation wall, grade beam, or slab at an elevation consistent with the top of the slab or terminate at impediments, such as water stops or dowels. Extend vapor barrier over the tops of pile caps and grade beams to a distance acceptable to the structural engineer.

- Lap all joints a minimum of 6 inches and seal laps in accordance with manufacturer’s recommendations.

- Seal all penetrations like utilities and columns per the manufacturer’s recommendations.

The summarized instructions are paraphrased from ASTM E 1643. Remember that every project presents its own unique challenges and specific moisture barrier needs. Always fully review ASTM E 1643, architectural and structural details, local building codes, and manufacturers recommendations prior to installation.

More Best Practices

High-performance vapor barriers keep moisture and soil gasses in check. Photo courtesy of ISI Building Products

Clinch the best shot at properly protecting your investment from the ground up with a high-performance under-slab vapor barrier system.

Whether you’re installing an expensive finished flooring system or planning for the future, I highly recommend getting the moisture barrier right the first time to avoid much larger expenses and potential health concerns down the road.

In summary, choosing the best products for below slab protection should include products:

- Made from virgin resin

- Made using co-extrusion technology

- Exceeding ASTM E 1745 Class A

- Meeting vapor barrier criteria

- Tested for long term performance

- Accompanied by detailed installation instructions

ISI Building Products has all the necessary accessories to go along with a successful vapor barrier installation. ISI Building Products has specialized in below slab water vapor and soil gas protection for more than 15 years. Our Viper vapor barrier line has become an industry recognized brand for commercial and residential applications. Our track record supports our knowledge in this field and we take great pride in providing solutions for all of your vapor retarder and barrier needs.