Story at a glance:

- Modern steel has reduced greenhouse gas emissions and energy intensiveness significantly in the last 25 years.

- Terrazzo and natural stone both date back hundreds of years as reliable building materials.

- Precast concrete’s off-site manufacturing ensures rapid installation any time of year.

LEED certifications, the Living Building Challenge, GreenGuard—with so many different building certifications out there, where do you start when you know you simply want to use the best sustainable building materials out there?

The team at gb&d has compiled a list of sustainable building materials and their pluses and minuses so you can make the best decision possible on your next residential or commercial project.

Aluminum

The connections between the aluminum curtain wall, the floor-to-ceiling windows, and the steel, tubular columns appear seamless and effortless, while the shape of Springdale Library, designed by RDH Architects, was inspired by the site’s overall triangular geometry. Photo by Nic Lehoux

Aluminum is a helpful and sturdy building material that helps structures meet their energy efficiency goals. With significant design flexibility and applications everywhere from building frames to sunshades and stairwells, aluminum is a cost-effective option to have in mind for future projects.

When upgrading a framing system, aluminum frames are cost-effective and environmentally sound. The important consideration with aluminum frames is that in order to have high thermal performance, thermal breaks must separate the aluminum frame on the outside from the heat-controlled inside to avoid contact heat transfer.

Thermal break technology reduces heat loss during cold weather and yields warm interior surface temperatures on the frames, preventing condensation and increasing the thermal performance still more. Altogether, recent technologies have allowed aluminum to shake its past and become a strong, lasting, energy-efficient material.

Aluminum’s main advantages are that it is 100% recyclable, durable, and able to take many forms. Fixed sunshades integrated with a building’s architecture are a popular way to bring visual interest and energy savings. It is not flammable and requires very little upkeep as it does not rust or rot, making aluminum siding, all-terrain staircases, ramp systems, and prefab aluminum balconies useful applications as well.

Pro: Aluminum is 100% recyclable and easily customizable.

Con: Not traditionally energy-efficient—requires modern technologies to work at its best.

Best Use: Anywhere wood could be used but that requires more long-term durability and fire safety without significant maintenance is a good application for aluminum.

Steel

Prefabricated steel buildings go up quicker than if you were to use traditional building materials, as they arrive pre-cut and preinsulated, eliminating the need for a host of traditional subcontractors and saving both time and money. Photo courtesy of EcoSteel

Modern-day steel-making is remarkably, well, modern.

Over the past 25 years, the North American steel industry has significantly reduced its environmental impact—reducing energy intensity and greenhouse gas emissions by more than a third, making the production of steel more sustainable than many competing products, according to the American Iron and Steel Institute.

“The industry is constantly striving to make the steel production process as efficient as possible. In fact, we’re rapidly approaching the efficiency limits defined by the laws of physics with the current technology we have. This is why AISI (American Iron and Steel Institute) is working to develop breakthrough steelmaking technologies,” Brandie Sebastian, director of life cycle assessment at the Steel Recycling Institute (SRI), told gb&d.

Steel is known for its strength and ability to bear heavy loads. These qualities allow it to be used in cantilevers, framing for expansive windows, and more. Plus, prefabricated steel frames, like those by EcoSteel, offer durability, low maintenance, and exceptional energy performance.

One of steel’s most appealing attributes is that it can be recycled continuously without losing strength. “It’s one of the few construction products that is not only recycled routinely, but it can be 100% recycled—meaning any steel product can be recycled into any other steel product,” Mark Thimons, vice president of sustainability for the Steel Market Development Institute (SMDI) unit of the AISI, told gb&d.

Pro: Steel is entirely recyclable and remarkably strong.

Con: Steel costs more upfront, and production requires significant energy.

Best Use: Steel’s ability to stand up to rust and rot with little to no maintenance, combined with its ability to seal tightly, make it a good choice for everything from building frames to swimming pools.

Wood

An FSC-certified Garapa rainscreen was vertically installed at the Dairy Farmers of America in Kansas. Photo courtesy of Wood Haven

Wood is arguably the only truly renewable building material. With nearly endless treatment options and styles, wood offers incredible aesthetics and function tailored to its application.

The Forest Stewardship Council and others offer certifications to guarantee wood is sustainably sourced and responsibly harvested. Hardwood is best for projects like Wood Haven’s sculptural rainscreens and cladding. Varieties of hardwood can be so dense they sink in water, making them feasible options for outdoor applications and projects that must stand up to time and the elements.

When hardwood is unavailable or out of budget, soft wood can be thermally modified to become durable and sturdy enough to serve the same purpose. Another option is to use CLT, which is a kind of mass timber processed and fused together for superior strength. CLT is inherently fire resistant and embodies a significant amount of carbon. Thermally modified timber (TMT) is a natural wood product that has undergone a chemical change using heat and steam to improve outdoor stability. Arbor Wood’s thermally modified wood siding and decking can suit a range of design trends, whether you want an urban loft or a cabin in the woods.

Timber is a natural insulator, offers biophilic appeal, and is one of the sturdiest and most traditional materials available for structural building elements.

Pro: As a truly renewable resource, wood is beautiful and structurally sound.

Con: Only hardwood or engineered soft wood is truly usable.

Best Use: Mass timber and CLT are fantastic options for building structures.

Bamboo

Trinity Bamboo. Photo by Roger Turk, Northlight Photography

Bamboo easily makes the ranks of the most sustainable building materials with its regrowth rate of 15 years or less, making it one of the most renewable resources.

Bamboo comes in several different forms: fused bamboo, unfurled bamboo, strand bamboo, and bamboo strips. Fused bamboo is processed and reinforced with adhesives to make it stronger and sturdier while maintaining its biophilic aesthetics. Fused bamboo is low maintenance and doesn’t rot.

Unfurled bamboo is bamboo culm that is flattened under heat and pressure, keeping the bamboo skin intact. Strand bamboo, a great option for flooring, is compressed to become denser and stronger, and it offers the classic, natural bamboo grain. Each form of bamboo is useful in different applications, but all offer the same benefits of renewability and biophilia.

Pro: Bamboo is a quickly renewed building material.

Con: Bamboo is not by nature the most durable building material.

Best Use: Strand bamboo flooring offers many applications and impressive sturdiness.

Terrazzo

The Duke Ellington School of the Arts in DC features poured-in-place epoxy terrazzo. Photo courtesy of Terrazzo & Marble Supply Companies

Terrazzo dates back hundreds of years, but today is used in almost exclusively sustainable context. By incorporating small pieces of marble, granite, or even recycled glass to cement or epoxy resin binders, terrazzo offers beautifully speckled floors and other surfaces that can last the lifetime of the building itself.

Modeled after 20th-century Italian work, Terrazzo & Marble Supply Companies has nicknamed their terrazzo “forever floors.” The company’s signature epoxy allows them to incorporate materials like aluminum, zinc, and brass, along with recycled products like glass, porcelain, marble, and even beer bottles as aggregate. “We take a lot of things that would be put into the waste stream that we can reclaim and reuse in a terrazzo floor,” James Bateman, division manager of the company, told gb&d.

But flooring is not the only use for terrazzo. With sophisticated epoxy resins, the granite, marble, recycled glass, or other materials incorporated can offer distinct style when put to use as countertops, tiles, and just about any other surface in a space. They offgas very little, making terrazzo a benefit to occupant wellness as well as overall sustainability.

Pro: Long lifespan with little maintenance. Plus, it is customizable as you can specify the epoxy color and the size, shape, and material of the flecks in the terrazzo.

Con: Relatively expensive compared to other flooring solutions.

Best Use: Terrazzo is most commonly incorporated as flooring or countertops.

Precast Concrete

Photo Courtesy of Fabcon

Precast concrete goes up fast and performs for years and years. With fully insulated layers to bring the R-value up, precast concrete offers a quick and sustainable solution for building everything from warehouses to recreation centers.

Precast concrete is known to be resilient in varying weather conditions and climates and capable of maximizing the footprint of a building with height. Fabcon produces the tallest load-bearing concrete wall panels in the US.

“We’ve built from Canada to Florida, in different climates and building types, from office buildings to food storage—where they need an extremely high R-value,” Dave Stanton, sales engineer at Fabcon, told gb&d. Fabcon’s R-values range from 16 to over 28, and achieve a 50 Sound Transmission Coefficient, blocking outside elements and noise.

Precast concrete allows for a less disruptive construction site, as the panels are made offsite and shipped to be rapidly installed. This also means that precast panels can be built throughout the seasons. Once installed, precast concrete’s high R-value results in a big return on investment in just a few years, and the walls continue to bear loads for years to come with very little maintenance required.

Pro: Quick to install with high R-values for impressive building envelopes.

Con: Can be expensive, depending on the requirements of the building.

Best Use: Wall panels of precast concrete are ideal for warehouses or other buildings with tall ceilings, where the precast panels actually cut down on the cost of insulation by being fully insulated as is.

Natural Stone

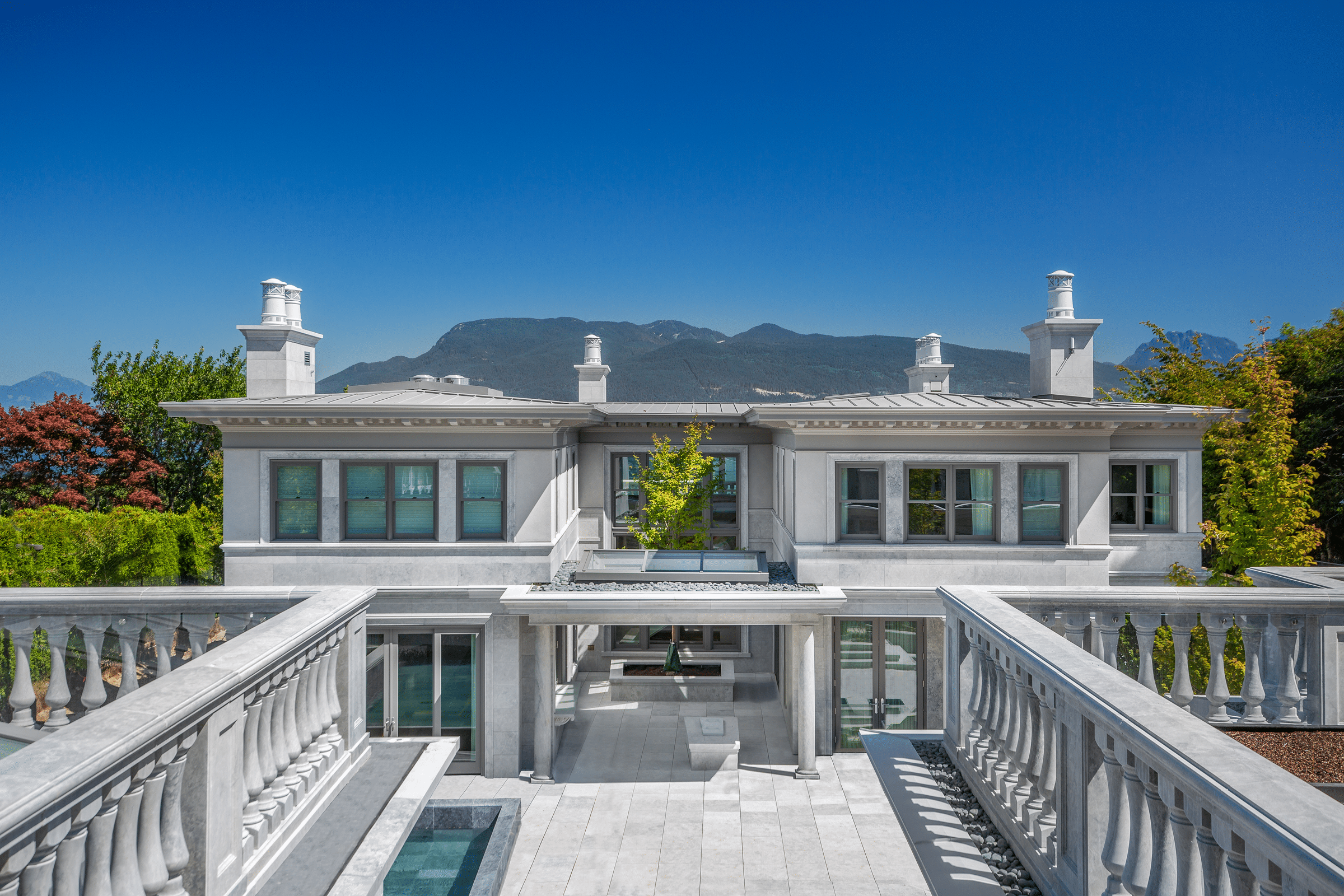

This neoclassical private residence in Vancouver was built with Polycor’s SAINT CLAIR Fleuri Marble from Oklahoma, fabricated and installed by Red Leaf Stone. Photo courtesy of Polycor

Natural stone makes the list thanks to its being low maintenance and durable and its minimal carbon footprint.

Like wood, 100% natural stone offers a degree of biophilia and surprising design flexibility. Polycor offers sustainably sourced stone, from bright white granite to gray marble, for lasting design. “Natural stone is very versatile. It offers a wider range of sizes and formats and a multitude of styles that concrete and other cast products can’t,” Hugo Vega, Polycor’s vice president of commercial and institutional sales, told gb&d.

Because natural stone comes straight from earth, it does not emit VOCs and has very low embodied carbon. When implemented in an indoor or outdoor space, natural stone withstands high traffic and natural elements—just think of how long the Parthenon or Great Wall of China have been standing.

Natural stone panels like those offered at Biesanz Stone are also a good alternative to other wall panels. “They require a lot less structural members, structural steel, or concrete to support the structure because they are so lightweight on the project,” Todd Shaffer, head of drafting/design at Biesanz Stone, told gb&d.

Thanks to the fact that stone is all natural, it is easy to recycle or reuse. “Extraction requires only a small energy expenditure. It can be easily disposed of and recycled since natural stone does not contain any major pollutants,” Tolga Altug of Materials Marketing said in an interview with gb&d.

Pro: 100% natural stone is lasting, versatile, and extremely sustainable.

Con: Natural stone, particularly certain varieties like granite and marble, can be more expensive than other materials.

Best Use: Natural stone’s durability lends itself strongly to flooring, where it can last decades.