Story at a glance:

- Embodied carbon is a significant component of Scope 3 emissions, often overshadowed by more readily measurable operational sources.

- Unlike operational emissions, embodied carbon locked in once a building is constructed, making early decision making critically important.

- In the face of an imperfect regulatory landscape, a lack of perfect data, and complex value chains, delaying action on embodied carbon is tempting, but delay is costly.

In the global effort to decarbonize the built environment, operational carbon—the emissions from lighting, heating, cooling, and powering buildings—has long been in the spotlight. Yet as buildings grow more energy-efficient and renewable energy use increases, a less visible but equally impactful culprit emerges: embodied carbon.

Embodied carbon, the emissions associated with material extraction, manufacturing, transportation, and construction—is a significant component of Scope 3 emissions, often overshadowed by more readily measurable operational sources. While operational emissions accumulate over time, embodied carbon is locked in at the outset.

For many infrastructure projects, this initial carbon load can account for 50% or more of total life cycle emissions. As the urgency to reduce emissions increases, it’s becoming clear that we can no longer overlook embodied carbon as a critical part of the climate.

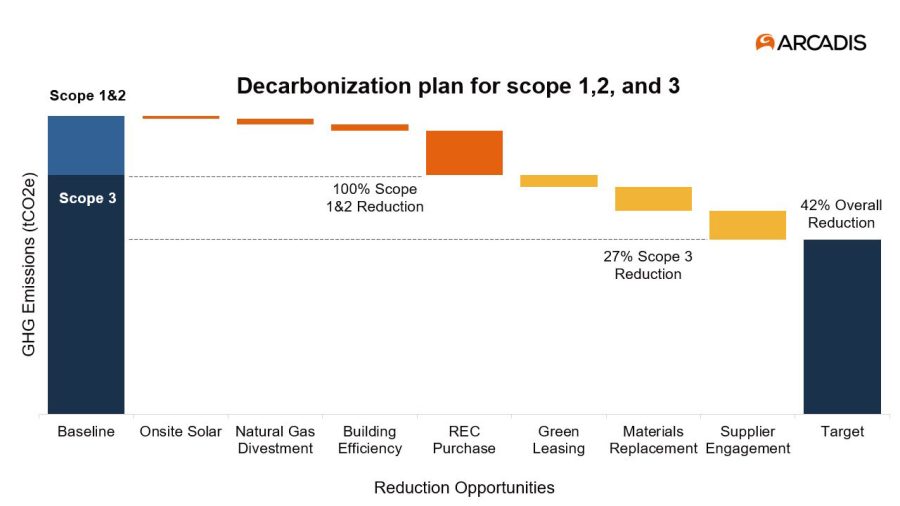

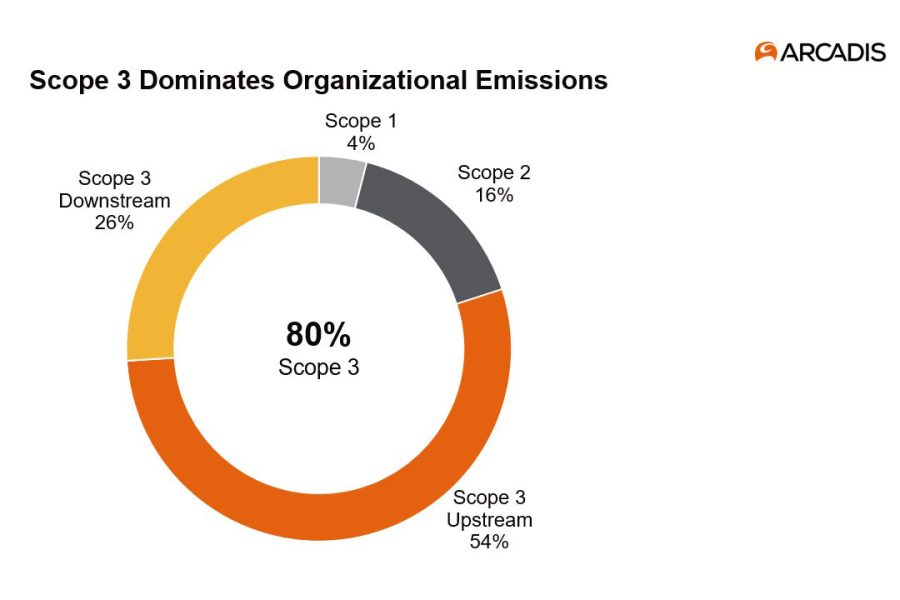

Scope 3 emissions present unique challenges for companies because they lie outside direct operational control. Yet they account for the lion’s share of emissions for many organizations, sometimes 70 to 90%. Within that, embodied carbon remains one of the most opaque and under-addressed aspects. Even as the SEC backs away from enforcing climate disclosure rules, pressure from investors, consumers, and global regulators for greater climate transparency continues to mount. Embodied carbon reduction can no longer be optional.

Unpacking Scope 3 & Embodied Carbon

The Greenhouse Gas Protocol divides emissions into three scopes:

Scope 1: Direct emissions from owned or controlled sources

Scope 2: Indirect emissions from purchased electricity, steam, heating, and cooling

Scope 3: All other indirect emissions across the value chain

Scope 3 emissions span 15 categories, ranging from purchased goods and services to business travel and the use and disposal of sold products. Embodied carbon falls under categories 1 (Purchased Goods and Services) and 2 (Capital Goods), making it a central concern for the construction, manufacturing, and infrastructure sectors.

Unlike operational emissions, which can be monitored and adjusted over time, embodied carbon is “front-loaded.” Once a building is constructed, the emissions tied to its materials and construction methods are effectively locked in. That makes early-stage decision-making critically important.

Why Measuring Embodied Carbon is So Difficult

Image courtesy of Arcadis

Despite its importance, embodied carbon is notoriously tricky to measure. Most of the challenges stem from data availability, standardization, and accountability.

Supplier Data Gaps

Data quality is one of the biggest hurdles in addressing Scope 3 emissions. Supplier emissions data is often inconsistent, unavailable, or unverifiable. Many manufacturers do not produce Environmental Product Declarations (EPDs)—standardized reports outlining a product’s life cycle environmental impact—and even when EPDs exist, variations in methodology make comparisons difficult. This lack of consistency leads to uncertainty in embodied carbon estimates and reduces trust in reported reductions.

Complex Supply Chains

The complexity of the construction supply chain is another challenge. With multiple tiers of subcontractors and vendors, influence becomes diluted. Design teams may specify low-carbon materials, but contractors and suppliers often default to what’s available, familiar, or cheapest. Traditional project delivery models often misalign sustainability goals and procurement decisions.

Cost Premiums and Delivery Risks

Low-carbon alternatives may come at a cost premium or with delivery risks, deterring suppliers. Project owners can create incentive structures that reward carbon-conscious choices, such as giving preference to suppliers with verified EPDs, awarding points for low-carbon innovation in tenders, or offering extended contracts for suppliers who align with long-term sustainability goals.

Limited Industry Pressure

Reporting is crucial. Without a clear reporting structure, carbon performance is challenging to manage, let alone improve. Many projects treat sustainability reporting as a separate, end-of-project task rather than integrating it into project governance.

Embedding carbon metrics into project management systems and aligning with climate reporting frameworks ensures emissions performance is tracked throughout design, procurement, and construction, not just audited after the fact.

These hurdles often lead to what we might call “data paralysis”—the inability to act due to uncertainty or lack of perfect data.

Case Study: The Ontario Line Project

The Ontario Line in Toronto is a multibillion-dollar rapid transit line and one of the largest infrastructure projects in Canada’s history. Arcadis provides design and engineering services in partnership with Infrastructure Ontario and Metrolinx as part of the Connect 6ix consortium.

What sets the Ontario Line project apart is its explicit integration of sustainability and emissions reduction. This strategy includes tracking and minimizing embodied carbon across design and construction.

The Ontario Line tackles Scope 3 and embodied carbon by:

Material optimization: Arcadis and project partners are applying strategies like material reuse, low-carbon concrete, and alternative steel options to reduce emissions during construction.

Digital modeling and life cycle analysis: Virtual design and construction tools help the team visualize the impact of emissions in early design phases. This proactive approach allows for smarter material choices and more efficient building practices.

Supply chain engagement: Working closely with suppliers and subcontractors, the project team is improving transparency in material sourcing and emissions accounting, which is crucial for better Scope 3 reporting.

Whole-life carbon thinking: Instead of focusing only on short-term construction emissions, the Ontario Line incorporates whole-life carbon assessments, factoring in materials and construction, maintenance, and eventual end-of-life reuse or recycling.

As governments worldwide push for net-zero infrastructure, projects like the Ontario Line serve as scalable models for embodied carbon reduction in public works.

Navigating a Shifting Regulatory Landscape

The regulatory environment around climate disclosure is evolving rapidly. In March 2024 the SEC adopted a climate-related disclosure rule requiring US public companies to report certain climate-related risks and, for some, Scope 1 and 2 emissions. This version that passed the initial vote had dropped Scope 3 requirements. A year later, however, the SEC dropped the rule entirely, citing legal and political pressures.

While the regulatory environment is in flux, public companies are still under increasing pressure from investors, clients, and some state and international markets to report on Scope 3 emissions. Furthermore, governments are adopting frameworks such as the International Sustainability Standards Board. While Omnibus has slowed the European Union’s Corporate Sustainability Reporting Directive, the discussion is ongoing, and the bar is rising.

The message is clear: Long-term accountability for Scope 3 emissions—including embodied carbon—is inevitable regardless of near-term mandates.

Practical Strategies to Move from Reporting to Action

Image courtesy of Arcadis

What steps can companies take to lower embodied carbon in the context of Scope 3, especially given the uncertainty they may face?

1. Prioritize early design integration. The earlier companies consider embodied carbon in a project’s life cycle, the more options become available. Low-carbon concrete mixes, mass timber, or recycled steel may not be feasible if considered too late in design development.

2. Focus on hotspots, not perfection. Use the 80/20 rule: Identify the high-impact materials (e.g., concrete, steel, aluminum) that contribute the most to embodied carbon, and focus efforts there. Directionally correct estimates can drive real impact, even without perfect data.

3. Apply circular economy principles. Applying circular economy principles can reduce embodied carbon, such as reusing concrete from demolition, specifying recycled steel, or designing components for disassembly and reuse. These strategies reduce emissions, cut waste, and contribute to broader resource efficiency goals.

4. Leverage product-specific data. Encourage suppliers to provide EPDs. Use reputable databases like the Embodied Carbon in Construction Calculator (EC3) or Inventory of Carbon & Energy to guide material decisions where unavailable.

5. Engage suppliers as partners. Rather than demanding perfect reporting, meet suppliers where they are. Provide education and incentives for low-carbon practices, such as preferred vendor status or extended contracts.

6. Collaborate across the industry. Organizations like the Carbon Leadership Forum and Building Transparency are helping create shared databases and tools that standardize carbon accounting. Cross-sector collaboration can reduce duplication and accelerate progress.

The Role of Innovation and Digital Tools

Technology plays a crucial role in reducing embodied carbon, with emerging tools that enable design teams to simulate the carbon impact of their decisions in real time.

Life Cycle Assessment (LCA) software like OneClick LCA, Tally, and Athena allows architects and engineers to evaluate the emissions associated with various materials and construction processes. Integrating LCA into Building Information Modeling (BIM) workflows further enhances the accuracy of carbon accounting during the design phase, leading to more informed decisions.

Additionally, AI and machine learning are being used to develop predictive models that assist teams in identifying low-carbon material alternatives and forecasting emissions outcomes based on different design iterations. As a result industry leaders in the AEC sector are increasingly incorporating these tools into their workflows to facilitate sustainable decision-making at scale.

Looking Ahead: Progress Over Perfection

Reducing embodied carbon and Scope 3 emissions isn’t just about data or regulation. It’s about a cultural transformation within the industry.

As climate risk becomes business risk, forward-looking firms are rethinking how they measure success. Financial metrics are no longer enough; environmental performance, supply chain transparency, and emissions intensity are becoming part of the bottom line.

In the face of an imperfect regulatory landscape, a lack of perfect data, and complex value chains, delaying action on Scope 3 and embodied carbon is tempting. But delay comes at a cost.

The most successful organizations won’t be those that wait for regulations to force their hand. They’ll be the ones that lean in—prioritizing the most significant sources of emissions, investing in partnerships, and embedding carbon reduction into every decision.

Embodied carbon may be hidden in our buildings’ walls, floors, and foundations, but it doesn’t have to be invisible to our strategies. With the right tools, partnerships, and mindset, we can build greener structures and a lower-carbon economy.

Ian Minnes contributed to this article.