Story at a glance:

- Decarbonization refers to the process of significantly reducing the amount of CO2 and other greenhouse gasses being emitted as a result of human activities.

- Decarbonization can be achieved by improving the energy efficiency of various industries, transitioning to renewable energy sources, electrification, adopting cleaner-burning fuels, and capturing, storing, and utilizing carbon.

- Companies like Kimberly-Clark Professional, Tarkett, Skanska, and the Kingspan Group have all taken steps to drastically reduce their carbon footprints.

At the 2015 United Nations Climate Change Conference, 196 nations signed the Paris Agreement, a legally binding international treaty on climate change mitigation, adaptation, and finance. The stated goal of the Paris Agreement is to limit Earth’s warming to below 2℃ (3.6℉) above pre-industrial levels, with 1.5℃ (2.7℉) being the agreed-upon threshold.

For this goal to be realized, however, carbon and other greenhouse gas (GHG) emissions must be drastically reduced over the next several decades—and decarbonization is a crucial factor in curbing those emissions.

In this article we explore the basics of decarbonization, including what it is, the benefits and challenges that come with it, strategies for reducing carbon emissions across various sectors, and take a look at a few companies that have committed to decarbonizing their operations.

What is Decarbonization?

The experts at Kimberly Clark Professional say that energy-focused initiatives are decarbonization strategies that offer environmental and economic benefits. Photo courtesy of Kimberly Clark Professional

Decarbonization refers to those strategies and methods used to reduce the amount of carbon and other GHG emissions emitted through the combustion of fossil fuels, as well as the capture and storage of existing emissions from the atmosphere. Decarbonization goes hand-in-hand with the concept of net zero, or the state in which the amount of emissions produced are balanced by the amount removed from the atmosphere.

Why is Decarbonization Important?

Carbon dioxide and other GHG emissions are the leading contributors to advanced climate change, followed closely by the destruction of habitats (e.g. forests, grasslands, and oceans) that sequester carbon. If we hope to avoid total climate catastrophe and ensure the planet’s livability for future generations, global temperature increase must be limited to 1.5℃ above pre-industrial levels.

Reducing GHG emissions is integral to mitigating and eventually reversing the worst effects of our drastically changing climate, and achieving net zero at the global scale—particularly with regard to CO2 emissions—is absolutely necessary because it represents the point at which global warming effectively stops. Current estimates suggest that in order to avoid crossing the 1.5℃ threshold, global emissions must be reduced by 45% by 2030 and net zero must be reached by 2050.

Pathways to Decarbonization

The Clean Energy Transition Institute has identified five core pathways to achieving decarbonization at the global level: improving energy efficiency, transitioning to cleaner electricity, electrification, adoption of clean fuels, and carbon capture.

Energy Efficiency

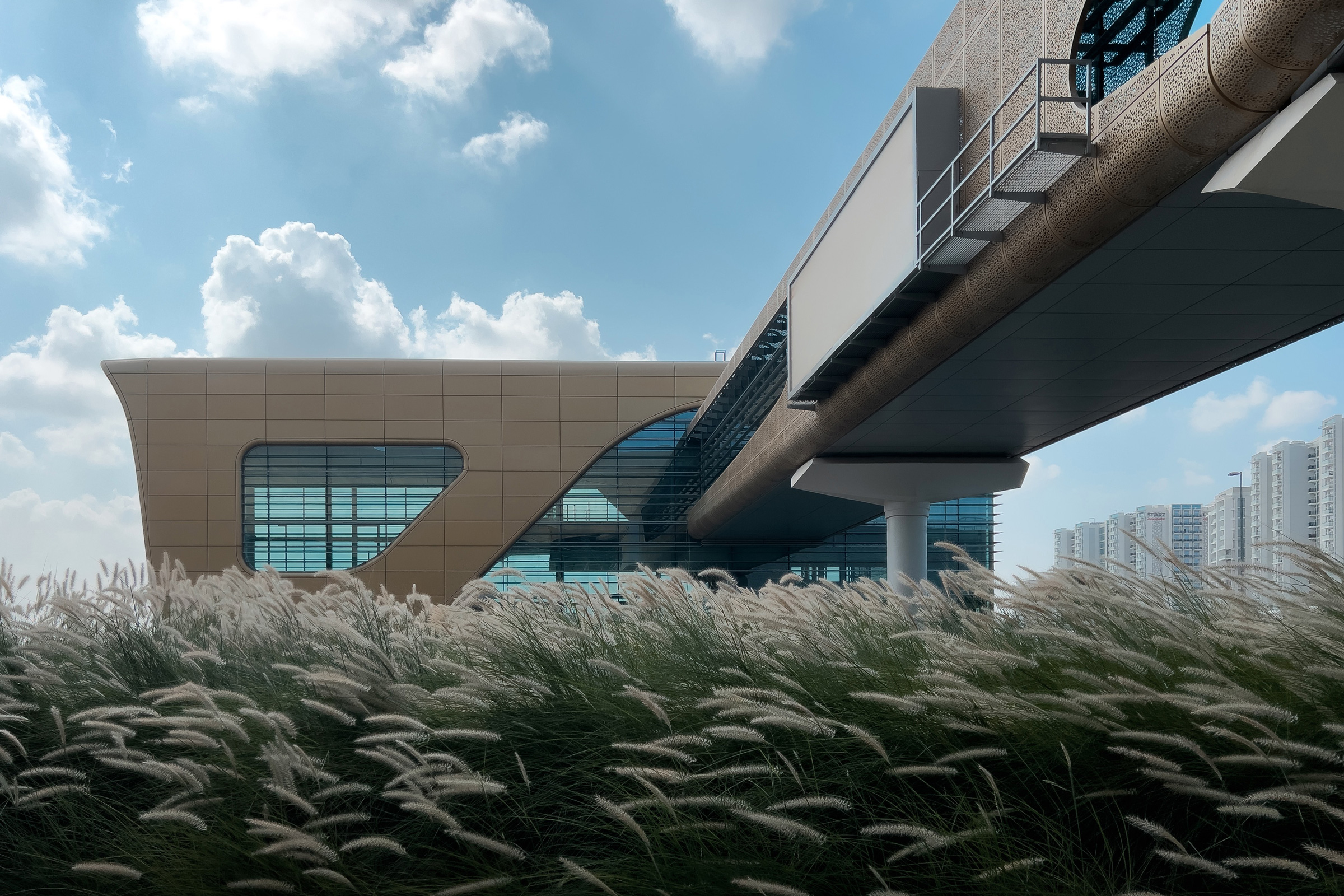

An energy-efficient envelope, passive ventilation strategies, and shading from the roof reduce energy consumption. Photo by Hufton+Crow Photography

Improving the baseline energy efficiency of products, buildings, manufacturing processes, industries, and economic sectors as a whole is the first step to reducing emissions. The reason for this is simple: maximizing energy efficiency means less energy is needed, which in turn means less energy is consumed.

Energy efficiency is beneficial even if the electricity being used is generated by renewable sources, as reduced energy usage means less demand on the grid to supply power, minimizing the risk of blackouts or energy shortages.

Renewable Energy

Covestro says clean energy must power the circular economy. Image courtesy of Covestro

Transitioning the globe’s power grids to cleaner, renewable energy sources like solar, wind, hydro, geothermal, and even nuclear power is one of the single most effective ways to reduce GHG emissions by a significant margin in a relatively short amount of time. Making the switch to renewable energy also means investing in large-scale electricity storage, particularly for intermittent energy sources like solar and wind that are not available at all times.

Electrification

Tech Square 3 is planned to be grid-aware, meaning the all-electric building can shift demand to lower its overall carbon intensity. Rendering courtesy of EskewDumezRipple

Electrification refers to the process of actually replacing existing end-use technologies powered by the burning of fossil fuels—e.g. gas boilers, internal combustion engines, furnaces, et cetera—with technologies that use clean electricity as a more sustainable source of energy.

Electric vehicles are perhaps the most well-known example of current electrification efforts but work is being done in other sectors as well. The US steel industry, for instance, has started the process of electrification by manufacturing all hot-rolled steel sections via electric arc furnaces. These furnaces use electricity to melt steel scrap into new steel and produce 75% less CO2 emissions than traditional blast furnaces, which burn coke—a coal-based fuel with an extremely high carbon content—to smelt iron ore.

Clean Fuels

Geneva Rock Products’ fleet of compressed natural gas trucks emit 90% less carbon than traditional diesel trucks. Photo courtesy of Geneva Rock

In instances where electrification simply isn’t possible, feasible, or realistic—such as in long-haul trucking, cargo ships, planes, and many industrial processes—fossil fuels should be replaced with cleaner-burning fuels like compressed natural gas, green hydrogen, electrofuels, and biofuels. Green hydrogen is a fuel created via electrolysis and involves splitting the oxygen and hydrogen molecules in water. As long as the electrolysis process is powered by clean, renewable electricity, green hydrogen is a virtually carbon-free alternative to traditional fossil fuels.

Electrofuels—or E-fuels—on the other hand, are synthetic carbon-based fuels designed to replace conventional drop-in liquid fossil fuels like diesel and methanol. Electrofuels are produced using captured carbon dioxide or carbon monoxide and hydrogen obtained from water split by clean electricity sources. When burned, electrofuels produce roughly the same amount of carbon used in their manufacturing, essentially making them carbon neutral. E-fuels are a viable option for reducing GHG emissions produced by air, marine, and long-distance freight transportation.

Biofuel is another cleaner-burning alternative to conventional fossil fuels and is produced from biomass derived either from plants or agricultural, industrial, or domestic bio-waste. Like E-fuels, biofuels are considered carbon-neutral as the only carbon they emit is that which was sequestered by the organic matter used to produce them.

Carbon Capture & Utilization

Photo courtesy of Carbfix

Any technologies that cannot be electrified or converted to cleaner fuel sources should be equipped with solutions that capture their emissions. Carbon can be captured onsite as it is produced or removed directly from the atmosphere after the fact. “The direct air capture method is important for capturing emissions that cannot be captured directly, such as CO2 emissions from airplanes,” Sandra Ósk Snæbjörnsdóttir, the geoscientist at the helm of Carbfix, told gb&d in a previous article.

After the CO2 is captured and separated it is then compressed into a liquid form to make it easier to store and transport. Once compressed, the captured carbon is then transported to a storage site, where it is typically injected into geological formations—like saline aquifers, depleted oil reservoirs, or basalt deposits—and left to form carbonate rock. Basalt is especially well-suited to this as it contains many of the necessary metals for efficient mineralization.

Alternatively, captured carbon can be used as an ingredient in other products, a process known as carbon capture utilization (CCU). CCU involves using captured carbon directly (i.e. not altered at the chemical level) or indirectly (i.e. transformed) in the production of products like carbonated beverages, fertilizer, and some of the aforementioned cleaner-burning fuels.

Decarbonizing the Built Environment

Taking into account both operational emissions and the emissions produced by materials and construction, buildings are responsible for roughly 40% of all global emissions. As a result, decarbonizing the built environment is integral to achieving global net zero goals and climate change mitigation efforts.

There are three core methods for reducing emissions in the built environment: onsite renewable energy production, improvements to building energy efficiency, and the use of low-carbon materials/products.

Onsite Renewable Energy

The Urban Frontier House achieved LEED Platinum. Photo by Nathan Satran

An ideal green building is capable of producing its own energy via renewable energy sources such as wind, solar, geothermal, or hydropower. Incorporating renewable energy into a building’s design is the first step in creating a zero-energy or positive-energy structure, which in turn reduces dependency on fossil fuels.

Solar is the most popular renewable energy source but is by no means the only option. The Urban Frontier House in Montana, for example, utilizes wind energy as well as solar, while countries like Iceland—which is powered almost exclusively by renewable energy—have demonstrated just how viable geothermal and hydro-power can be.

Improved Energy Efficiency

The design stacks kitchens and baths to create economies during construction. All units benefit from daylighting, operable windows, low-VOC materials, and energy-efficient appliances. Photo by Andrew Rugge

Decarbonizing the built environment also means reducing the amount of energy required to run the spaces we live, work, and learn in—that is, it requires improvements in energy efficiency.

A building’s energy efficiency can be improved by:

- Utilizing building performance modeling software. To better understand a building’s projected energy use, architects and engineers are encouraged to use building performance modeling software early on in the design process to help simulate everything from energy and daylight models to hygrothermal modeling.

- Integrating passive design systems. Buildings that leverage natural phenomena to their advantage by way of passive systems consume far less energy than those that rely on active systems; common passive design strategies include natural ventilation, passive solar design, daylighting, and so on.

- Improving insulation and air sealing. A building’s overall energy-efficiency can be improved further through the use of rigorous insulation and air sealing technology to create an airtight building envelope that prevents heat from entering or escaping.

- Installation of energy-efficient appliances. Installing appliances and other mechanical systems with low-energy requirements—such as those certified by ENERGY STAR—can help reduce a structure’s overall energy demands.

- Long-term monitoring. After completion, it’s important to monitor a building’s performance and energy use for the long-term, as this can help identify problem areas that may be improved upon and reduce emissions production even further.

Use of Low-Carbon Materials

The Andy Quattlebaum Outdoor Recreation Center at Clemson University is a prominent example of a wellness-driven building, designed to emphasize natural materials—most prominently mass timber. Photo by Jonathan Hillyer

Of course, a building’s carbon footprint encompasses more than just the CO2 produced during its operation; it also includes the embodied carbon of its materials. Architects can help decarbonize the built environment by choosing materials and products with a low embodied carbon. This includes materials that are naturally low-carbon—like mass timber, bamboo, rammed earth, et cetera—as well as low-carbon versions of traditionally high-carbon materials, like concrete.

Prometheus Materials, for example, has developed a zero-carbon alternative to limestone-based concrete called ProZero. ProZero is created by stimulating microalgae to create biomineralized calcium carbonate—the same process that creates coral reefs and seashells—that is then dried and used as the basis for bio-cement. In this manner ProZero avoids the carbon-intensive operations involved in manufacturing traditional cement. Microalgae also absorbs carbon as it grows, meaning ProZero sequesters carbon throughout its operational lifespan, reducing its carbon footprint even further.

ProZero is 15 to 20% lighter, possesses comparable compressive strength, and far exceeds the flexural strength of conventional concrete. “This degree of flexural strength will open up quite a few new market opportunities that traditional concrete just can’t fulfill,” Loren Burnett, president, CEO, and cofounder of Prometheus Materials, previously told gb&d.

Challenges of Decarbonization

Otovo helps home owners find the best price and installer for solar panels, all without a home visit. Photo courtesy of Otovo

Despite the benefits that come from decarbonizing various industries and operations, efforts to decarbonize at the global level have been slow to take off. One of the reasons for this is that the technology required to decarbonize at the scale necessary to reach net zero goals is still in its early stages. Carbon capture, utilization, and storage technology is effective at reducing emissions, but still has room for improvement and is not yet equipped for large-scale implementation.

There are also financial challenges associated with decarbonization. Despite being projected to be profitable in the long term, decarbonization requires hefty investments in the short term—investments that are often perceived as risky by stakeholders. Clean-burning fuels, for instance, are often two to three times more expensive than their fossil fuel counterparts. Moreover, the amount of money that has already been invested in the power grid and fossil fuel infrastructure—even by the average person—means switching to renewable energy will be a costly endeavor for all.

At the end of the day the biggest obstacle to widespread decarbonization is the decades of lobbying and misinformation campaigns led by fossil fuel interests, of which have heavily influenced political decisions and policies.

Decarbonization in Action: Case Studies & Examples

Now that we have a better understanding of what decarbonization is and how it may be achieved in various contexts, let’s take a look at a few companies that have committed to drastically reducing their carbon emissions.

Kimberly-Clark Professional

Kimberly-Clark Professional has committed to reducing their carbon emissions all along the value chain. Photo courtesy of Kimberly Clark Professional

A leading manufacturer of hygiene solutions for workplaces, Kimberly-Clark Professional has a long history of sustainable, ethical business practices. Ranked #2 on Barron’s list of the most sustainable companies in the US and a nine-time honoree on Ethisphere’s list of the World’s Most Ethical Companies, Kimberly-Clark Professional has demonstrated their commitment towards decarbonization in more ways than one.

A series of upgrades relating to operational energy efficiency in 2019, for example, helped the company reduce their CO2 emissions by 435,000 metric tons. In 2022 Kimberly-Clark managed to achieve a 42% absolute reduction in GHG emissions, amounting to a reduction of 65,000 metric tons of CO2 from the previous year.

But Kimberly-Clark Professional’s decarbonization efforts go beyond reducing their own scope 1 and 2 emissions—the company has also made strides in addressing their indirect scope 3 emissions. “It’s not just about our direct carbon emissions. It’s about getting carbon emission data from up and down our supply chain,” Lena Heidel, sustainability manager at Kimberly-Clark Professional, previously told gb&d. “Carbon emissions from the manufacturing of the raw materials and all the way through to the finished goods disposal at end-of-life have an impact to our climate.”

In 2011 Kimberly-Clark developed the RightCycle Program—the first large-scale recycling program for non-hazardous lab, cleanroom, and industrial waste—to help divert single-use PPE waste from landfills. Kimberly-Clark has also partnered with various recycling specialist companies to help customers recycle their old hygiene equipment.

Tarkett

Photo courtesy of Tarkett

Tarkett is another company that has taken serious strides to reduce their carbon footprint. A global leader in innovative flooring products, Tarkett’s decarbonization initiatives target all of their value chain emissions, with the company aiming for a 30% reduction across all three scopes by 2030.

“It’s really important to understand that the carbon footprint of a single product is only one indicator of sustainability,” Tal Fegan, senior vice president of strategic accounts and commercial business at Tarkett, told gb&d in a previous publication. “I think the more important thing is to partner with a manufacturer who accurately, transparently communicates the action being taken on a corporate level to measure and lower their overall greenhouse gas emissions. No one organization is going to solve climate change. All stakeholders—from manufacturer to designer to end user to contractor—need to come together to make frequent, incremental change to the status quo.”

Tarkett sources all of their materials from ethical, sustainable suppliers and has assessed nearly all of their raw materials to ensure compliance with Cradle to Cradle’s rigorous standards for human and environmental health. Tarkett’s commitment towards reducing their downstream scope 3 emissions, on the other hand, is exemplified by their ReStart program, a take-back and recycling initiative that aims to support a circular economy by preventing old flooring from entering landfills.

Tarkett also recognizes the importance of transparency and publishes straightforward documents outlining the human and environmental impact of each of their products, as well as their lifecycle carbon emissions, that may be easily accessed via their website. This commitment towards transparency earned Tarkett an A- score for their climate change impact by the Carbon Disclosure Project (CDP)—the world’s leading environmental disclosure platform—placing them at the leadership level of the CDP’s grading system.

Skanska

The design of 1550 on the Green in Houston incorporates plentiful indents, allowing for more corner offices. Skanska’s Heidi Creighton points to the project’s beautiful metal framing and aluminum fins. “We’ve been pretty focused on steel and concrete to date, but I think the facades are also going to be an important focus. We can make some great strides there.” Photo courtesy of Skanska

Originally established in 1887 as a concrete manufacturer, Skanska is one of the largest sustainable construction and development companies in the world. Skanska’s ambitious sustainability goals go beyond most federal commitments: the company has developed a plan to reach net zero by 2045 and is aiming for a 70% reduction in their scope 1 and 2 emissions by 2030.

Skanska is also targeting reductions in scope 3 emissions on both ends of the value chain by working with suppliers who are just as committed to sustainability as they are and building aggressive sustainability goals into each of their projects. “We set a target for all of our projects and do everything we can to indicate to the market that this is a key priority for us—and that we’re going to focus on low carbon materials because I think it’s so important for the supply chain to see those signals that the large buyers really want this,” Heidi Creighton, former national head of sustainability for Skanska USA Commercial Development, now principal of Creighton Sustainability Advisors, previously told gb&d.

In 2023, Skanska further demonstrated their commitment towards carbon reduction by co-creating the AGC task force—to spearhead decarbonization efforts in construction—and the AGC Decarbonization and Carbon Reporting Playbook to help contractors track and report their projects’ GHG emissions.

Kingspan Group

In 2022 Kingspan harvested 26.1 million liters of rainwater, progressing toward a target of 100 million liters of rainwater annually harvested by 2030. The IKON Global Innovation Center—Kingspan’s headquarters in Ireland, uses nearly every Kingspan product manufactured as a sort of showcase of possibility. Photo courtesy of Kingspan Light + Air

One company that has taken massive steps to decarbonize their operations is the Kingspan Group, a premier building materials manufacturer that specializes in daylighting solutions, insulation, and architectural facades.

This is seen in Kingspan’s partnering with Bullfrog Power—Canada’s leading green energy provider—in 2018 to provide their North American facilities with low-carbon biogas, a green natural gas that harnesses energy from organic waste. The only CO2 released by biogas is that which the organic waste would have naturally produced as it broke down, meaning no net new carbon is added to the atmosphere.

In 2019 Kingspan successfully achieved net zero energy status and would go on to develop the Planet Passionate program the following year, in which the company laid out their 10-year plan to decarbonize their entire operational footprint. Aside from continued investment in green biogas, Kingspan’s Planet Passionate program also involves transitioning the company’s manufacturing sites over to at least 60% direct renewable energy by 2030.

“Across the globe every business we own is in the process of installing onsite generation—be it solar, wind, geothermal, or other technology,” Brent Trenga, Kingspan’s North American director of sustainability, previously told gb&d. In 2022 Kingspan successfully reduced their scope 1 and 2 emissions by 26%, putting them well on their way to meeting their 2030 net zero emissions target.