Story at a glance:

- Viega’s MegaPress Press-In Branch Connector gets jobs done up to 90% quicker—and safely.

- An expanded valves lineup from Viega also saves teams time and money.

Viega is always innovating. Among their standout creations is the MegaPress Press-in Branch Connector, as well as a recently expanded valve lineup.

The Press-In Branch Connector came out about three years ago and still there’s nothing like it on the market. It’s such a special innovation that it continues to get a lot of attention, says Colton Henkowski, a Viega technical training consultant. “No one else makes a press fitting like it.”

Typically, welding a branch connection onto an already installed header pipe is long and tedious work. It requires almost total access to the pipe, extreme welding skill, and all of the additional safety precautions you’d expect from hot work.

The Viega MegaPress Press-in Branch Connector makes that work safer and easier. It’s up to 90% faster and doesn’t require welding. It can also be done using the same standard press tool used for Viega ProPress and MegaPress fittings, with the addition of the Press-in Branch Connector Tool Kit. It’s approved just like all the other MegaPress systems. “People think it’s a separate fitting or system, but if you had an engineer who approved MegaPress on the job, they approved the MegaPress branch connector as well because it’s part of the same line.”

The Branch Connector in Detail

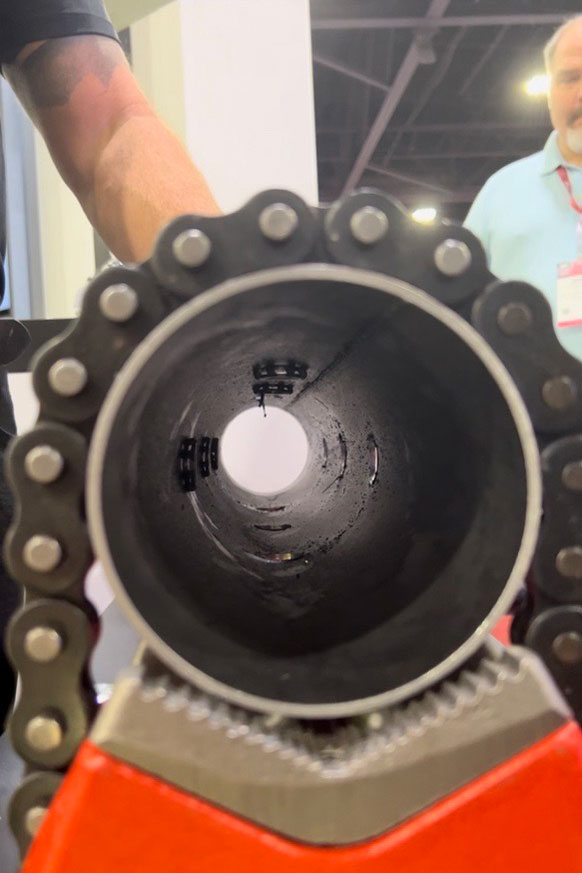

- Inside pipe view of Branch Connector. Photo courtesy of Viega

- Photo courtesy of Viega

The MegaPress Press-in Branch Connector is designed for schedule 10 and schedule 40 carbon steel pipes. The press-in branch connector creates a three-quarter-inch NPT threaded connection in accordance with ASME B1.20.1. It has an external zinc nickel coating and is available in sizes of one-and-a-half to four or six inches.

“This connection method is a press fit. You drill a square hole, insert the fitting with the clamp, and it pulls apart the metal tight against the inside of the pipe and seals the sealing element to the base,” Henkowski says. “We’re taking something that’s normally a 20- to 25-minute weld and the most likely to leak weld on the job because it’s a hard weld—there are a lot of angles to hit—and we’re turning it into a minute to a minute-and-a-half press connection. We can do that from an inch-and-a-half all the way up to a six-inch pipe with a three-quarter inch threaded outlet on it.”

We’re turning it into a minute to a minute-and-a-half press connection.

A separate press-in branch connector is available for different pipe dimensions. The press-in branch connector is fitted with a sealing element made of EPDM or FKM. The press-in branch connectors are marked with a green dot for EPDM and a white dot for FKM.

Where to Use the Branch Connector

MegaPress G. Photo courtesy of Viega

The branch connector is especially helpful where space is at a premium—like in pipe manifold installation for sensors, thermometers, or drains.

The Press-in Branch Connector can be used with black, galvanized, industrially painted, powder-coated, seamless steel pipes or steel pipes welded along the longitudinal seam.

It can also be used on low pressure steam systems, on compressed air, or anywhere the FKM or EPDM sealing elements are already used.

“What I see a lot in the field is thermometer outlet, pressure outlet, chemical feed lines, and anything where they need to put a small line into a big pipe really simply and quickly. The branch connector is the way to go,” Henkowski says.

More Branch Connector Benefits

Viega’s Branch Connector requires no welding and poses no fire hazard, which is particularly important in restoration or retrofit work. The press fittings are installed with a battery-powered or corded pressing tool.

“It’s less expensive than putting in a T,” Henkowski says. “If you do have a branch and, say, you’re on a chilled water line and need a three-quarter-inch branch off a two-and-a-half-inch line, it’s easy. It’s less expensive and you don’t have to cut the T and get the pipes to move back and forth.”

Installing Viega MegaPress fitting system also means:

- Up to 90% time savings

- Proven joining technology

- Technical field support

- No fire watch needed

- No special certification required

More recently Viega also released an expanded MegaPress valve lineup, pushing the industry even further, Henkowski says.

Expanded MegaPress Valve Lineup

- MegaPress G. Photo courtesy of Viega

- The MegaPress G family. Photo courtesy of Viega

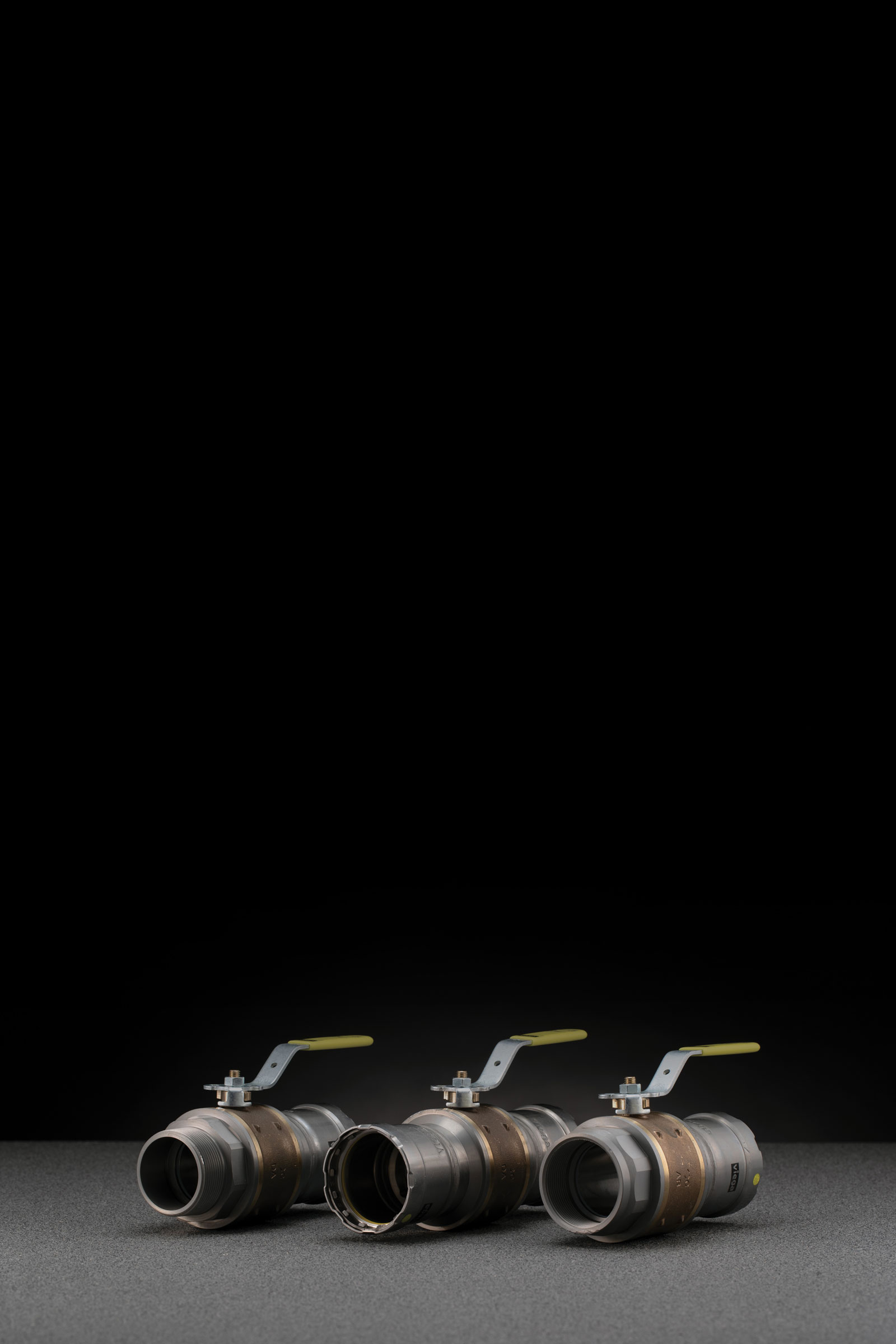

In April 2023 Viega announced its new sizing for ball valves in the MegaPress system. Where in the past they offered a three-piece valve connection—great for heavy industry or systems where you need to break down the valve, clean the system, replace seats, and so forth—they now also offer a two-piece MegaPress valve.

“It’s a less expensive method. Instead of having to pay for all those extra parts and pieces on a system, you choose that two-piece method. It’s something people were looking for,” Henkowski says.

The Viega MegaPress portfolio offers maintenance-free MegaPress ball valves that enable fast, safe, and efficient installation from half-inch to four inches. When working with a larger diameter pipe, you usually have to move from threading to welding. The new MegaPressG Ball Valve is a two-piece method that swaps brass for a steel body with zinc nickel coating. The valve has a three-point ISO actuator mounting pad with a control valve and lockable handle. The larger diameter valves feature an HNBR sealing element at the press ends, compatible with fuel and gas applications and available in sizes two-and-a-half to four inches.

It also has a union built right into the valve. “That’s super important on gas systems because you have to have a means of disconnection at the unit. Instead of having to put in a threaded piece, a union, a threaded piece, a valve, and another threaded piece to get to the system, we sell that all in one part. It’s a little bit tighter and more concise on the installation. and it still gives you what you need out of a union.”

Check Valves

Check valves are an important part of a pump system, and they can stop media from backflowing to the pump and keep it from flowing in a specific direction. The new MegaPress 316 Check Valve (EPDM Sealing Element) is ideal for industrial applications—including potable water, rainwater, and chilled and hydronic water.

The Viega ProPress Manual Balancing Valve features an adjustable handle with an integral scale visible on the side used to increase or decrease the flow rate. The two pressure-test ports are used to measure the differential pressure across the seat of the valve, which can be used to calculate the flow rate. The ProPress Manual Balancing Valve is suitable for commercial applications, including potable and hydronic systems.