Story at a glance:

- Choosing the right building envelope is crucial when constructing a data center.

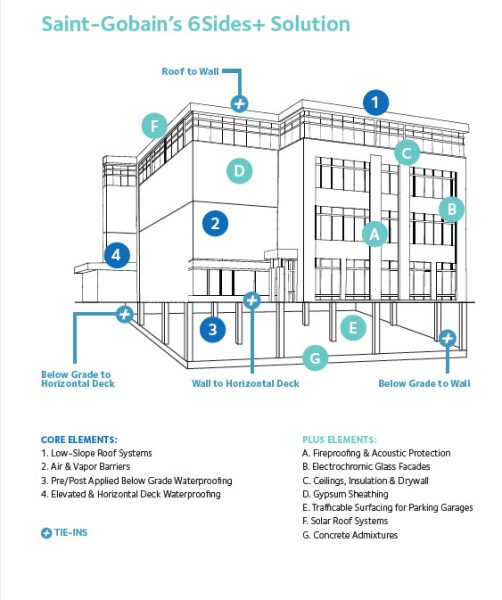

- GCP’s 6Sides+ system is an integrated, single-manufacturer waterproofing and air barrier portfolio that provides continuous protection from below-grade foundations through vertical walls, all under one warranty.

- The US is seeing a proliferation in the construction of data centers like never before.

Data centers are timely, they demand speed, and they require resilience built from the ground up. A surge in their construction demands attention, as these buildings store large amounts of data.

From 2015 to 2024 the value of private data center construction in the US has increased tenfold. In 2024 the private sector spent more than $28.3 billion on data center construction—approximately $10 billion more than the previous year.

High-performance processing, storage, networking, power, and cooling systems are only as stable as their exterior protection, though. That’s why the experts at GCP stress the importance of having a strong, reliable building envelope.

GCP data center expert and key markets segment manager Jennifer Vorberger recently shared some of her insights on the need in the industry as well as how GCP continues to innovate with much-needed solutions. Vorberger has been in the commercial construction industry for more than 25 years.

Photo courtesy of GCP

gb&d: How have building envelope products evolved in recent years?

Jennifer Vorberger: Systems are the new thing. Instead of individual products, systems of multiple products that work together and are warrantied as a single system are now being specified in the BE space.

From the basic weatherproofing products of yesterday to high-performance systems that are much more complex, integrated technology has entered the scene and Saint-Gobain (GCP’s parent company) embraces that.

Another big difference is a shift from individual products serving only one function to addressing multiple attributes between adjacent products whether it be a roof or a wall, where the whole system must balance air, water, vapor, and thermal. I think one of the big drivers of this has been the LEED movement over the last few decades. It’s a driver for energy, efficiency, and performance. The extreme weather events we’ve been seeing are also making resilient building envelopes even more important.

And then technology—the automation of manufacturing and the rise of digital twins. That’s something else Saint-Gobain embraces, and it employs predictive analytics. The outcomes are reduced cost to our bottom line as well as our customers’ and optimizing efficiencies. There have been a lot of technical advancements.

What’s required of a modern data center building envelope?

It must be resilient, offering high-performance consistently over time. Another must, is speed to market – can our products and system be installed faster and bring the project on-line rapidly. Sustainability is also a requirement for all hyperscalers—the big four tech companies. The building envelope has to be watertight, and airtightness is being demanded on the walls; it has to have protection from chemicals and contaminants in the soil and groundwater.

What should architects consider when it comes to data center roofs?

We’re seeing a lot of cool roofs and green roofs with some data centers. It helps because data centers are all about power, which emits a lot of heat, so they need to cool their structure so they can optimize their operational efficiency, impacting their bottom line. The cool roofs and green roofs both reduce heat absorption and can both incorporate solar systems. Green roofs specifically, can also manage stormwater.

When you’re dealing with a lot of high-value material like the IT equipment that data centers hold, and their goal is no latency, 100% uptime, they don’t want one drop of water in that roof. I’m a big proponent of multi-ply systems for mission-critical structures like this.

While the trend in commercial has gone towards single-ply, it’s important to consider multi-ply systems which provide redundant protection with multiple layers of waterproofing membranes. With equipment being installed and penetrations being made, single-ply roofs are more vulnerable to damage, requiring maintenance. When you’re dealing with a lot of high-value material like the IT equipment that data centers hold, and their goal is no latency, 100% uptime, they don’t want one drop of water in that roof. I’m a big proponent of multi-ply systems for mission-critical structures like this.

PERM-A-BARRIER in action. Photo courtesy of GCP

How have vapor barriers changed to meet need?

Vapor barriers historically didn’t work very well. Building science really put their money where their mouth was, energy codes got more stringent, and we started to see self-healing membranes arrive on the market.

In cold climates during the 1970s the oil crisis spurred energy efficiency across the world, and in the ’80s you started to see air vapor barriers getting more advanced. Air tightness of the building envelope became really important.

This is really where GCP had its shining moment. They launched their PERM-A-BARRIER product in the 1980s; basically the performance standards were developed for the industry by GCP with this product. They contributed to testing the full assembly, not just the parts, that became ASTM E2357. And PERM-A-BARRIER is still on the market today with a diverse line of liquid and sheet applied and permeable and impermeable solutions.

What about below-grade waterproofing?

It used to just be basically your asphaltic emulsions; an asphalt roof is an example of that. The asphaltic emulsions that were applied to masonry to stop the intrusion of water are now much more high-performing. They are synthetic rubbers, they’re polymer-based membranes, polyurea, and they’re self-healing membranes, like I mentioned before.

When projects have high risk profiles GCP’s PREPRUFE should be considered. Known to aggressively and fully bond to concrete and stop lateral water migration, this system has protected major commercial and industrial projects worldwide with a track record of success.

GCP’s SILCOR product, a polyurea based solution, is a spray-on product that goes on white and has no seams. It’s very successful against resistance to chemicals.

SWELLPRUFE bonds directly to poured concrete and shotcrete in blindside applications. SWELLPRUFE combines the self-sealing properties of bentonite with specially formulated rubberized asphalt sheets. Photo courtesy of GCP

Where do innovations like GCP’s new SWELLPRUFE come in?

This is another proof point of customer-centric R&D and product development. We listen to what our customers say and solve problems that they face in the field. SWELLPRUFE is a prime example of this mindset.

This product innovates on the traditional bentonite geotextile mats by providing a solution that is high performing and offers distinct benefits for the applicator. It’s a dual protection membrane which places encapsulated bentonite where it is needed while providing the bond to concrete on the top side that customers expect from GCP.

By thinking of ways to install products faster, safer and easier, we help projects stay on schedule for delivery.

What other innovations have you seen in the industry?

Innovation in terms of application, there are options for some products that can be spray-applied now, while some have taken advantage of self-adhesive membranes. Product development also tries to solve the labor shortage issues we have seen by creating solutions that are easier to install and take less people to do so.

Saint-Gobain also keeps a watchful eye on creating more light and sustainable solutions. It’s woven into the DNA of who we are as company. Products like our MONOKOTE® Fireproofing solutions enable embodied carbon savings on fairly large scale. Less carbon means lower global warming potential (GWP) which is a win for all stakeholders.

How is GCP helping data centers go up faster and more efficiently?

It’s all about, “What can we do to get our products to the market faster to help the hyperscaler?” Speed to market is the number one thing they need. Fast construction, short lead times, and ample capacity of products.

Everything is resilient, sustainable, and flexible. The developers, hyperscalers, and co-location providers want optionality for future expansion or the ability to reconfigure the existing new build in a couple of years or if they repurpose it and sell it for another function or another segment.

Being a part of the Saint-Gobain family, we can also help connect to other brands in the group which may have additional products and solutions to deliver better, more efficient Data Centers. Whether it be interior solutions, infrastructure, smart glass, concrete additives and more – so much of a project can be sourced with one phone call.

How are data centers different from other building projects?

The fast pace is very unique to data centers. They’ve gone from, maybe a decade ago, a 36-month construction schedule, which is pretty normal, down to 18 months, and now hyperscalers are even asking for 12 months. The hyperscalers are really pushing the envelope.

The gigawatt power is immense; it’s unprecedented. With all the investment in this segment, developers demand the best. On other commercial or industrial projects people may value engineers much more than on a data center project.

And data centers can be very controversial with the public. You hear things like, “They’re too loud. They’re ugly. We don’t want to pay the taxes.” Acoustics is a big, big thing. There still needs to be some public education. Many of the products that go into data centers could address these concerns or misconceptions. For example, some wall assemblies can provide acoustic attenuation which will quiet down the site and help them be a better neighbor.

What should architects ask before beginning a data center project?

One important topic is lateral water migration. The testing performances around that are so critical. The question I’d want architects to ask is: Does the manufacturer of the building envelope products you’re looking at provide tests on lateral water migration?. Our top products are tested for that. For instance, PREPRUFE, when that is put down for below-grade, that’s a permanent, cohesive bond with the concrete and it’s been tested for lateral water migration. Not all products are.

It’s also important to find out if there are site challenges with any contaminated soil. Typically a geotechnical report is provided. It’s very technical information. I don’t know if most architects really understand what they’re looking at. GCP has a team of building science and technical service engineers who are experts in assisting customers on how to solve these complex issues.

.

A few other things around the geography are: Is it seismic? That would entail a different solution. What are the high temperatures and low temperatures in the region? Is the site rural or urban? With data centers typically it’s a large footprint, and if they’re in the open they’re not as concerned about acoustics. If you’re in a more urban setting or in the city it’s probably going to be a taller structure. You’re going to need more load-bearingness on your concrete slab, and you’re going to have to pay attention to acoustics and aesthetics more.

Find out if the products you select are fast to install. Are they easy to install? Will they perform consistently over decades? What are the warranty considerations?

Know what you’re specifying when it comes to the building envelope because you really want it to work.

Drawing courtesy of GCP

What is the 6Sides+ System, and how do warranties factor in?

Warranties are a very important topic for all owners but especially with these data center owners. It’s important for architects to understand warranties, and a question I would ask would be: Are the adjacently installed products warrantied together as a system, like where the wall meets the ceiling? When you chose adjacent materials form one manufacturer, you have a single point of contact, and peace of mind that these tie-in details were purposefully designed to work together.

With systems and warranties of a building, you tend to get a lot of gray area. One of the purposes of our 6Sides+ program is to embrace that and let people know that with one company, Saint-Gobain, we have products for all six sides of your building and then some! A lot of warranties don’t include the tie-in detail where, say, a horizontal meets a vertical plane. They’ll include the horizontal and the vertical, but really where’s the problem going to occur? At the tie-in. Saint-Gobain is helping solve for that.

We’re trying to answer what we’ve seen the industry complaining about.

What sustainability metrics should architects consider?

The two metrics we’re seeing pop up often are EPDs, or Environmental Product Declarations—that’s a prerequisite—and then low carbon. Do these products have EPDs? Do these products have a low published GWP?

Then I would encourage architects to ask if manufacturers use sustainable practices in their sourcing and production, because there are Scope 1, 2, and 3 that need to be addressed. Finding out how a manufacturer sources and produces will answer those questions for them, including take-back programs, recycling programs, waste management on a jobsite; there’s a lot of different ways architects can meet their LEED points.

What misconceptions exist in the industry today?

Well, there’s a lot to know. It seems like every day there’s something more to know, and the data center segment is so dynamic and almost volatile. I’m predicting it’s the catalyst to new products to come. Based on immediate need, it’s the Gold Rush of today. Everybody wants to be a part of this growing ecosystem, but you really need to come with some good solutions because those are the ones that are going to get through the door.

There are many misconceptions about building envelopes. The building envelope is the central component of managing thermal and energy of the data center in all buildings. What I’ve heard lately has been all about the IT equipment and not the building. I think that was because there was a shortage of supply chain with the IT equipment.

In the last couple of months I’ve seen more emphasis on the building shell compared to power sources which remain a key factor. So it’s not that they don’t think the building is important. It was really all about the supply of equipment, the HVAC units, the exhaust fans, the computer equipment, and how to cool it. They’re still working on that, but now there’s a bit more bandwidth to talk about building envelope. My message is that it is very central. It affects the total cost of ownership for the owner. It affects the energy efficiency, the operational reliability. It affects uptime and having no latency, which is what these data centers want. They want uptime all the time.

What do future data centers look like?

They just keep getting bigger. There’s no longer just one building. They’re building higher. They’re building 625,000-square-foot footprints whereas they used to be 100 or 200. They’re building campuses and multiple campuses with multiple co-location providers joining forces—where they were competing before they’re now partnering to get a good land deal so they can build.

There’s a lot of interesting things that are happening as far as the size and how they’re getting there and faster.

It’s all about bigger and faster and more aesthetically pleasing. I’m excited about that, because they’re not so pretty. They’re kind of eyesores and that can affect real estate. So they’re looking at better integration into the local community and being more aesthetically pleasing. We’re going to see some more glazing, like glass facades for those that want to have that type of look, or maybe an iconic location for a hyperscaler.

We’re going to see more green roofs. It’s going to be a bit more warm and fuzzy and quieter.

But inside it’s not going to be warm and fuzzy; they’re going to be higher density, with more PUE. That’s their metric—power usage effectiveness. There are examples of creative problem solving going on to specifically address cooling challenges. Iron Mountain has a large data center underground in an abandoned limestone mine in Pennsylvania, for example. And then Microsoft tested in the waters off of Scotland how to use seawater to cool the equipment. There’s a lot of research with underwater, so that’s interesting, too.