Story at a glance:

- Gensler shares three strategies for delivering positive, measurable impact.

- The harvesting, manufacture, and transportation of raw materials used in building construction is responsible for 11% of global emissions.

- Mass timber is one example of the new, sustainable building materials available today.

Tackling climate action in the building industry starts with making conscious decisions about how building materials and climate change are related, looking closely at how the materials we build are manufactured and sourced. Today the harvesting, manufacture, and transportation of the raw materials used in building construction is responsible for 11% of global emissions, according to the Global Alliance for Building and Construction. These embodied carbon emissions account for roughly 30% of the total annual building sector emissions , and that number is growing.

Regardless of project type every building owner, occupant, architect, designer, and builder has an opportunity and responsibility to decrease embodied carbon levels throughout the built environment right now. In doing so, we are not only doing our part to mitigate the global impacts of climate change, but we can also deliver more climate resilient spaces and places for our fellow global citizens. Here we take a closer look at building materials and climate change with three strategies for delivering positive, measurable impact.

1. Reuse what you already have.

Image courtesy of Gensler

Generally speaking the longer materials are used, the better it is from a carbon emission perspective. While there are some exceptions, like replacing woefully inefficient single-pane windows with dual-pane insulated units—we are all best served when we can extend the life of the materials used in our buildings.

When it comes to reuse and carbon, scale really does matter, so we start with looking at the existing buildings we have. Keeping the existing structure in place but reskinning to improve daylight, views, energy efficiency, and community connectedness can deliver new Class A office space to the market with an embodied carbon footprint of 50 to 60% less than building new. At the same time, it can improve the building’s resiliency to more extreme climate events like longer heat waves, colder winters, and more intense winds.

When a building’s original use may no longer be its highest and best use, look to adaptive reuse. Whether converting a tired office building into a thriving new residential development or transitioning a lifeless shopping mall into a vibrant urban office campus, the embodied carbon footprint can be expected to be 30 to 50% lower than building new.

Beyond extending the life of core building components like the foundation and structure, we can also derive carbon savings by reusing interior materials. From workstations and task chairs to doors, carpet tiles, and ceiling panels, anything movable is a candidate for reuse. For example, in the design of our new San Diego office, we were able to reuse more than 60% of the furniture from our existing office, reducing our carbon footprint hundreds of tons compared to sourcing all new items.

2. Understand the impact of the new materials you typically specify.

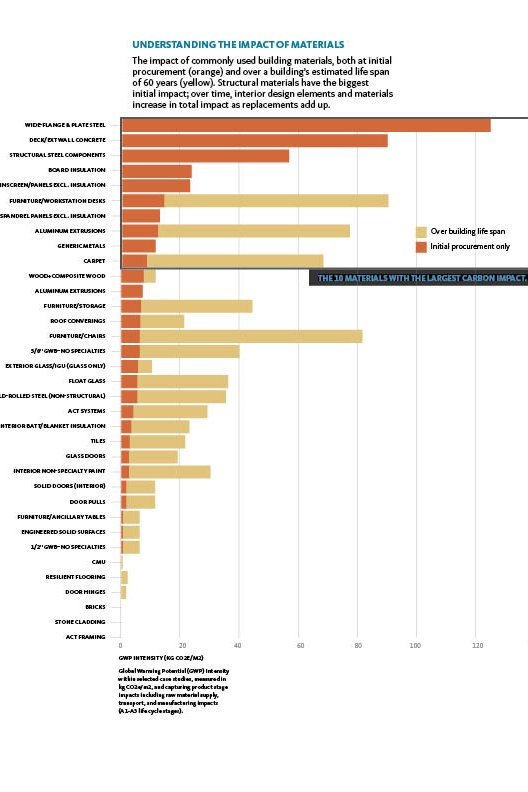

Chart courtesy of Gensler Research Institute

The carbon impact of commonly used building materials needs to be considered, both from initial procurement and over a building’s estimated life span of 60 years. As noted previously, structural materials have the biggest initial impact, but over time interior design elements like walls, furniture, and flooring increase in total impact as replacements add up.

To measure the carbon impact of various materials we look at what’s known as a product’s global warming potential (GWP). Calculating the GWP (which is often also referred to as embodied carbon footprint) relies on application of globally accepted life cycle-based assessment processes for the product category that details a standardized way to measure the greenhouse gas emissions associated with a product from material extraction through end-of-life disposal or recycling. Through the consistent application of these Product Category Rules (PCRs) we can understand the relative carbon impact of one product or structural system to another.

In any new building project today there are hundreds if not thousands of products used in the base construction as well as FF&E (furnishings, fixtures, and equipment). It is critical to not get overwhelmed by the sheer magnitude of information. We recommend using the 80/20 rule as your guide in figuring out what to focus on—20% of the products, whether because of their large individual footprint (such as concrete, steel, aluminum, or glass) or because of the quantity of material specified (wallboard, flooring, furniture) are driving 80% of the carbon footprint of your project or your company’s building portfolio. Direct your energy not to the one or two unique conference room tables but to the thousands of task chairs, the 25 stories of glass, and the 100,000 square feet of wallboard that collectively translate to large embodied carbon footprints that should be addressed.

3. Design with lower carbon alternatives

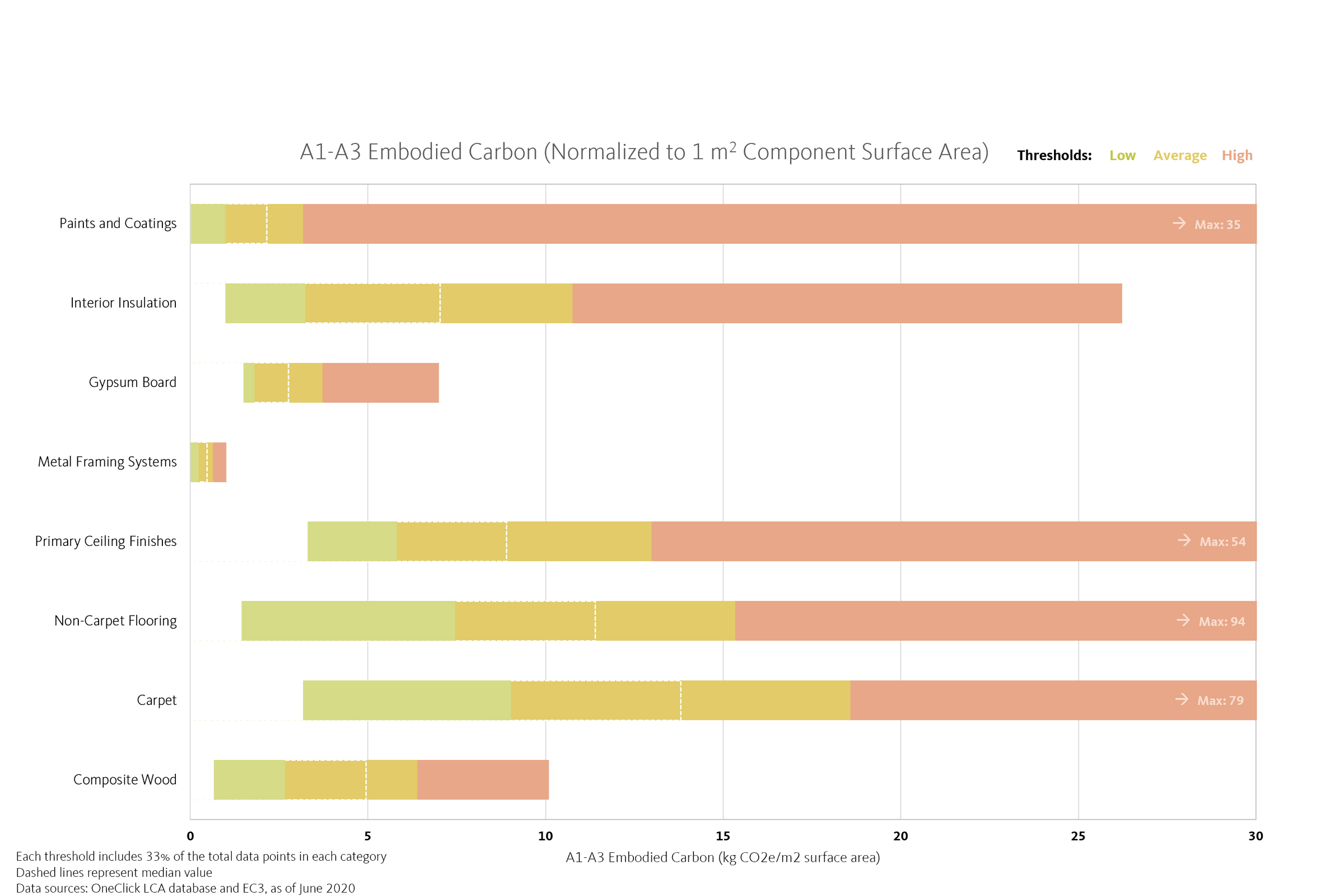

This graph depicting the embodied carbon footprint helps us understand the variability in today’s interiors products. Image courtesy of Gensler

The bigger the carbon footprint, whether due to material type or quantity specified, the more important it is to seek low-carbon variations and alternatives. Some products and materials are much further along than others in terms of offering a range of options with different GWPs. Manufacturers of concrete and steel, the two most dominant building materials today and the materials with the combined largest carbon footprints, are working aggressively to reduce the carbon impact of these materials. As designers, builders, and owners, the smartest thing we can do is move away from prescriptive based standards (e.g. specifying the exact cement, aggregate, and water ratios to be used) to performance-based standards (e.g. required strength, moisture, weight) and let the suppliers determine the best low-carbon formulas to achieve the required standards.

Mass timber is one example of new, sustainable building materials available today. It is made of timber pieces that are laminated together and form thick structural elements like cross laminated timber (CLT) panels. The material’s structural capabilities combined with its positive impact on carbon emissions is drawing increasing interest. However, attention needs to be paid to the sourcing of the wood to make sure sustainable forestry practices are being adhered to.

Prefabricated and modular construction elements can generally also be considered lower carbon alternatives, particularly due to much more efficient material usage. These construction systems both minimize the quantity of materials required and typically result in significantly less material wastage than bespoke on-site construction. Using less and wasting less both translate to overall lower carbon material footprints.

Moving to the interiors, an informed designer can easily find carpet tile, wallboard, ceiling materials, paints, and resilient flooring products with carbon footprints far below industry averages. A good place to start is focusing on those manufacturers with circular economy design in mind (products designed for reuse, disassembly and/or modularity) as well as high post-consumer recycled content.

Of course, it is also critical when considering alternatives that the right material be specified to account for the realistic future state. This is particularly important when dealing with ground floor spaces because changing climate conditions could subject the building to increased flooding or sea level rise stressors.

The means and methods behind how we work and the materials we specify play a crucial role in creating a sustainable and resilient future through every project we touch, with influence at every stage of the design process from conceptual design to post occupancy. The global AEC community, and its supply chain, must continue to innovate in low carbon solutions and continue to invest in analytical and data-driven design tools to enable the delivery of climate accountable, climate resilient projects around the world.