Driven by an increasing demand for high thermal and acoustic performance, transparency, and low maintenance costs, a number of facade innovations have been developed over the past 50 years.

Some notable developments include insulated glazing units, which became commercially viable in the 1960s and significantly improved the U-value of glazed wall systems. Shortly after in the 1970s, the concept of pressure-equalization in curtain wall design brought significant improvements in water management and reliability.

During the energy crisis of the 1970s, low-emissivity coatings were developed, and this technology was a significant advance in thermal performance, saving an estimated 1.5 quadrillion BTUs annually in the US market alone. These innovations were widely adopted and today form the basis of most curtain wall systems.

More recent advancements, collectively part of the emerging market of dynamic, adaptive facades, give designers the freedom to control energy loads and glare through the building envelope using building management software. Integrated, intelligent control systems are being developed to optimize energy performance and meet sustainability goals with no compromise to aesthetics and transparency.

What’s in the future for North American unitized curtain wall? In my opinion it’s the closed cavity facade.

What is a Closed Cavity Facade?

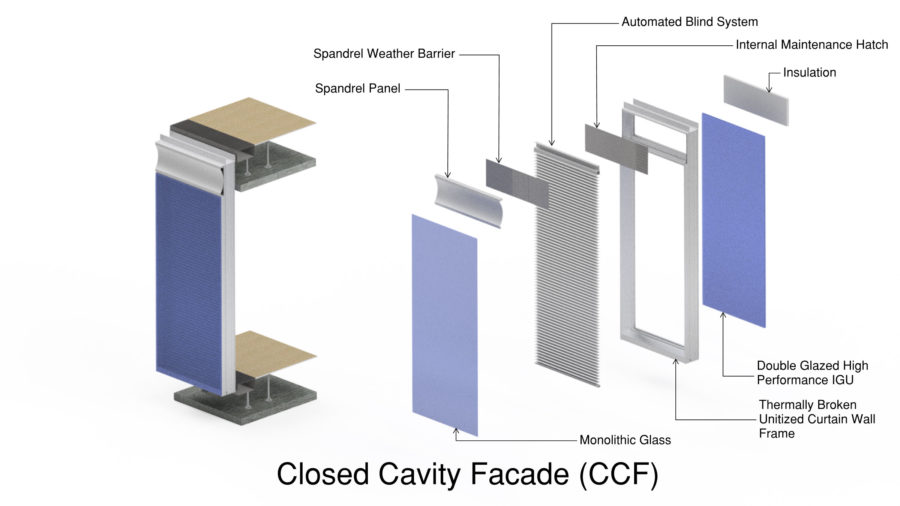

Closed cavity facade (CCF) is a variation of the traditional unitized curtain wall system. The vision areas of the facade are typically constructed of a single pane of glass at the exterior and a traditional double glazed unit (DGU) at the interior. Solar shading devices and shading controls are placed inside the cavity during factory assembly. A small, continuous flow of dry air is introduced into this cavity in order to prevent condensation. Exterior conditions are monitored, solar shading devices are controlled, and the flow of dry air into the cavity is regulated.

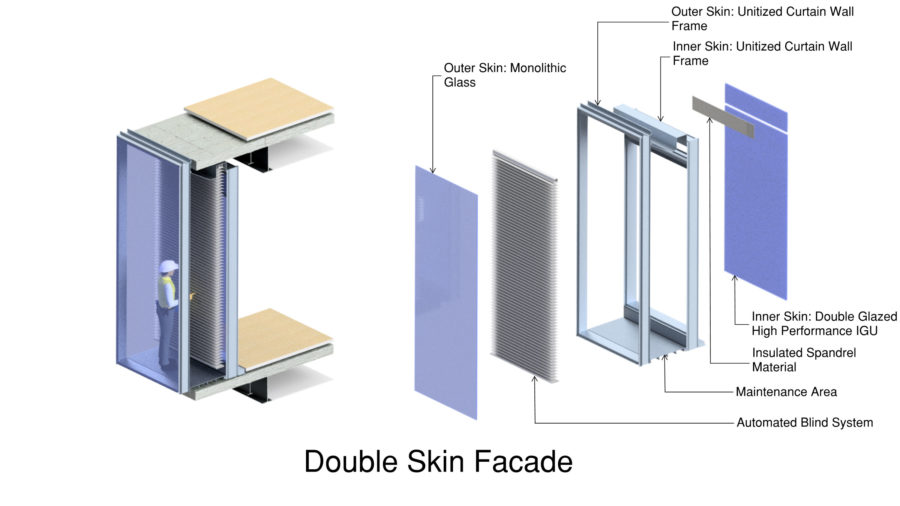

Double skin facades—which feature two distinct glazed wall assemblies separated by an air cavity (that decreases floor space) and typically include a shading device in the cavity—have been successfully used on a number of projects in Europe for the past 20 years, as well as a few in the US.

More recently developed is the compact double skin facade known as closed cavity facade. To date there are fewer applications of these closed cavity facades in the US market, due primarily to the lower cost of energy and less-stringent building codes.

Studies show that overall building energy consumption can be significantly reduced by the use of double-skin and closed cavity facades—by as much as 20% in most climates—relative to the baseline of traditional single skin curtain wall facade.

The Differences Between Traditional Single Skin Facades, Double Skin Facades, and Closed Cavity Facades

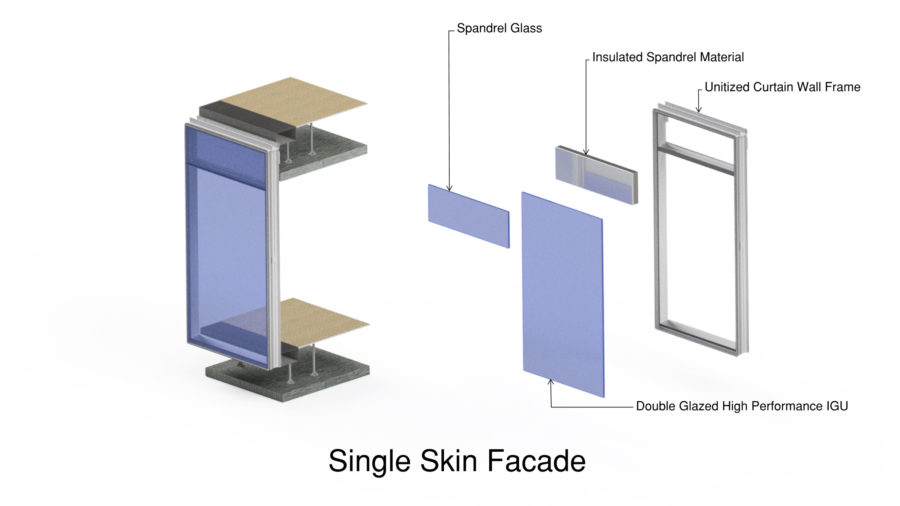

A single skin facade is a double-glazed unit (DGU) or triple-glazed unit (TGU) with internal blinds in the room and a high-performance low-E coating on the glass. The DGU is considered standard practice in most US cities today and serves as a baseline, while the TGU is sometimes considered for thermal and acoustic reasons.

- Courtesy of Permasteelisa

Double skin facades consist of a DGU on the outside and single glazing on the inside, creating a ventilated cavity where blinds can be integrated and indoor return air passing through the cavity of the double skin facade is ducted to the mechanical system or a double skin facade consisting of single glazing on the outside and a DGU on the inside, creating a ventilated cavity where blinds can be integrated and air flowing from outdoors through the cavity returning back to the outdoors via stack and/or wind effects.

- Courtesy of Permasteelisa

Today double skin facades are more prevalent in Europe than the US due to several factors, including:

- The higher cost of energy in the European market, requiring better thermal performance

- Familiarity of tradespeople with the systems, resulting in faster installation and lower cost

- More stringent building code requirements for energy performance

A closed cavity facade is a compact double skin facade consisting of single glazing on the outside and a DGU or TGU on the inside (with an overall system depth of 8 to 12 inches), creating a ventilated cavity where blinds can be integrated and a low volume of clean, dry air supplied to the cavity to prevent condensation and dust with the cavity at all times. This provides the thermal advantage of an exterior operable shading device without the high maintenance costs.

- Courtesy of Permasteelisa

Because the system is completely closed, it can be installed in the same manner as a traditional curtain wall unit. The shading controls are programmed by the blind control management software, which has several benefits: The facade can communicate with the HVAC system, the panels can be reprogrammed to account for changes in shading conditions (i.e. a new building adjacent), and one wall type can be used for all elevations and exposures.

The Benefits of Closed Cavity Facades

So what are the advantages of a close cavity facade versus other curtain wall systems?

- Excellent thermal performance in the transparent areas with U-values in the range of U-0.145 to U-0.15. (The overall U-value of the facade depends on the ratio of vision to spandrel area.)

- High degree of solar protection by the automated blind system.

- Reduced maintenance costs, as blinds are housed in a dust-free environment.

- In sunlight, expected internal facade temperatures are lower than a typical curtain wall system. This results in a lower degree of asymmetric temperatures at the building perimeter.

- Excellent acoustic performance.

- Close cavity facade walls can be designed to increase the life expectancy of the glazing units versus typical facades.

The evaluation of the viability of a close cavity facade should include the savings realized in the mechanical equipment, the cost of installing and maintaining a separate blind system, energy savings over the life of the building, as well as the less tangible benefits such as greater comfort for the building occupants and a higher allowable vision area for the facade.

What are the Expected Thermal Performance Values for Closed Cavity Facades?

With close cavity facades, you can expect the following thermal performance project-depending.

- A 30% to 50% improvement in U-value

- In cold weather climates interior surfaces will see significantly warmer temperatures

- Simplified exterior feature attachments

- Solar heat gain coefficient (SHGC) can see a 30% to 50% improvement

- Improved performance of an automated blind option

- Reduced need for high-performance and/or reflective coatings

- Photo courtesy of Permasteelisa

Why are Closed Cavity Facade Underutilized for Unitized Curtain Wall Systems in the US?

One of the biggest reasons is the North American market is developer-based and not owner-based for building construction. In my opinion the upfront costs of implementation often preclude many projects from conducting a deeper study of closed cavity facades; considering the potential savings to mechanical systems and also weighing the energy consumption of the building throughout its full life cycle could make closed cavity facades a viable option on certain projects.

Closed cavity facades would be the ideal solution for this problem with energy costs on the rise. Closed cavity facades out perform traditional single skin curtain walls thermally and acoustically and are a better option to maximize useable floor space over double skin facades.

Using a closed cavity facade would also be a great way gain LEED points for a project, as developers could also reduce the sizing of the mechanical systems as the system requirements would be less over the long run.

From an energy consumption point of view, our European counterparts have been leading the way in our industry for many years now with closed cavity facade systems. Over the life of a building, a closed cavity facade can save building owners unrealized energy costs if used in our current construction market.

Similar to the LED and incandescent light bulb transition in the early 2000s, most buyers are driven away from closed cavity facades because of the higher upfront costs that do not equate to the long-term energy efficiencies. Like LED light bulbs, closed cavity facades’ cost savings are realize in the overall life of the product through reduced mechanical loads.

With closed cavity facades, user comfort is improved from lower exterior temperature transference and acoustic performance. Building mechanical system sizes can be reduced because there will be less loss of energy over the building life, along with lower maintenance (no cavity to clean and no damage to the blinds), elimination of condensation in the cavity, more useable floor area, and faster installation.

Europe has been ahead of the North American market in this area for some years now with more stringent building performance codes and environmental concerns related to construction, but I think close cavity facades’ emergence in the US is right around the corner.