Airborne pathogens and aerosolization have become household phrases as the pandemic has taken hold, according to the experts at Filtration Group. Visit indoorairhygiene.com for practical recommendations on steps building architects, designers, and managers can take to protect occupants. Photo courtesy of Pixabay

Many of us need to upgrade our air filters to meet new MERV 13 ASHRAE guidelines.

It’s important to consider the indoor air quality protection rating (MERV) and total cost of ownership (TCO).

You’ve got the upfront cost of the filter, the labor to replace the filter, the disposal costs at the end of the filter’s life, and, most importantly, the cost of energy consumption.

It takes energy to push air through a filter, and typically the cost of that energy is over 80% of the TCO.

As an air filter extends past its service life, not only does it offer less respiratory protection, but the energy required to push air through it increases. So while using an air filter longer will save on the first three costs (and reduce the nuisance factor of replacement), if you make an air filter last too long, your TCO goes up.

In extreme cases, when an air filter is getting full and is overdue to be replaced, you may sacrifice product performance in a couple of weeks or even days. You’ll pay so much on energy you could have essentially bought another filter.

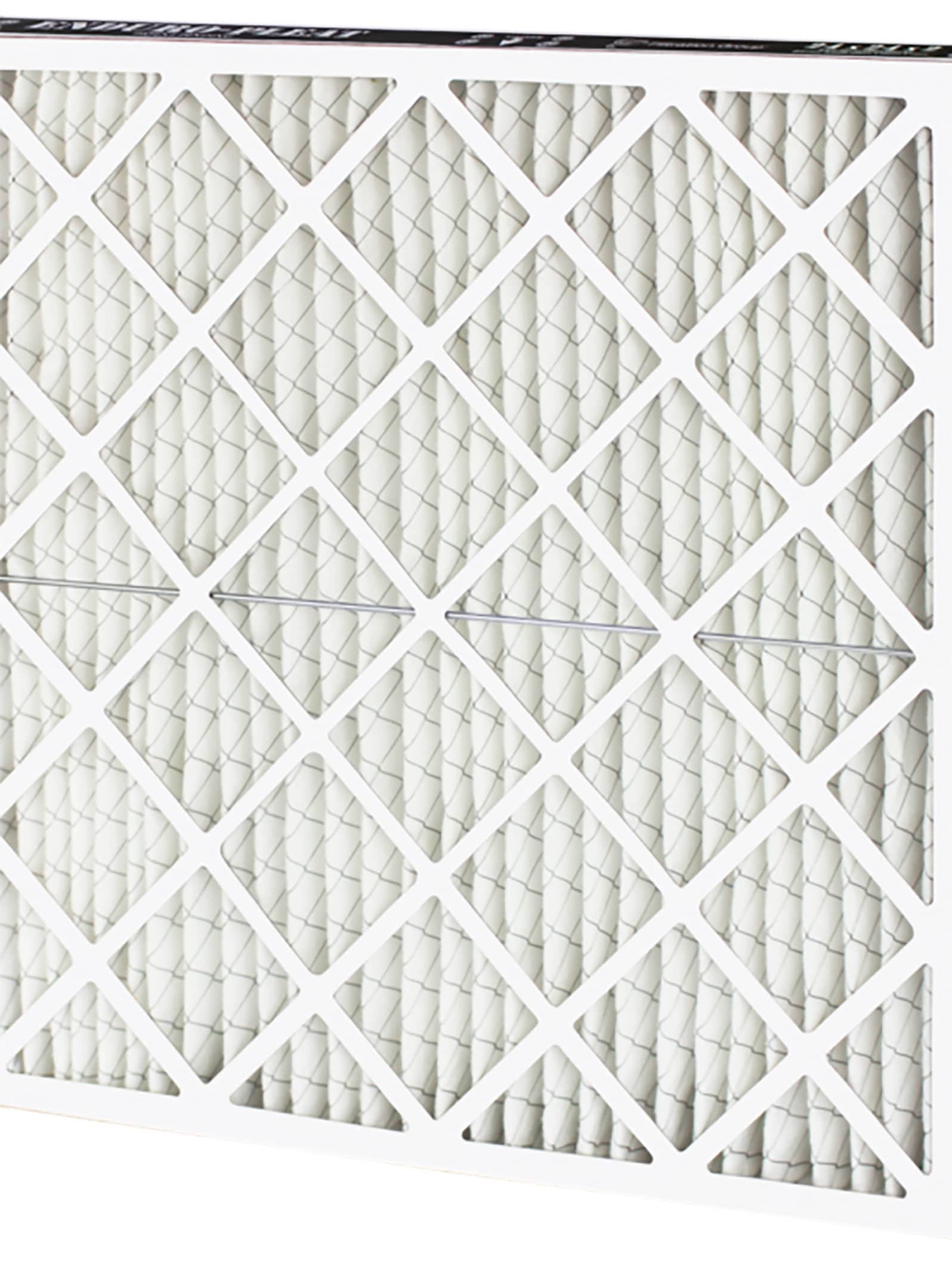

Photo courtesy of Filtration Group-HVAC

Some people are still deciding when to change their filters based on old rules and arbitrary round numbers, like waiting for your initial pressure drop to double. These one-size-fits-all rules need to be modernized to meet today’s safety and efficiency requirements. They ignore the factors that go into a complex TCO analysis for a sustainable commercial building.

Among other things, local energy costs, local labor rates, and the dust loading characteristics of the actual application can drastically affect how efficient and cost-effective a filter changeout is. We recommend the more media in your filter the better, generally; the initial pressure drop starts lower and stays lower as it takes longer for the media to fill up. Outside of that, it depends on your unique TCO analysis.

In general, our commitment to investment, innovation, and cross-pollination among our many filtration-focused businesses allows us to offer a robust line of industry-best indoor air filtration products that work with existing equipment. The traditional Enduro-Pleat® filter is built to last, the GeoPleat® offers tons of media in a compact size, and the FP V-Bank Minipleat offers the complete package of high filtration, energy efficiency, long life, and savings. For gas-phase filtration, the FP Dual-Pak version offers advanced air pollutant removal.

Michael Bruce, vice president of marketing and engineering at Filtration Group

Michael Bruce is vice president of marketing and engineering for Filtration Group-HVAC. Filtration Group is a US-based leader in the filtration industry.