Story at a glance:

- Designtex, a design and manufacturing company, recently launched the Rider, Tailor, and Wend collection.

- The new Designtex textiles include three high-performance upholstery fabrics in 52 colors and a variety of textures.

- The company invests in carbon reduction projects around the country to reduce or offset their total emissions.

In January 2021 American-based design and manufacturing company of applied materials, Designtex, released its new collection of sustainable textiles. The Rider, Tailor, and Wend collection consists of three high-performing upholstery fabrics that are perfect for sofas, chairs, side tables, and more.

No more worrying about staining your favorite fabrics: All three textiles are stain-resistant and cleanable with bleach, alcohol, and hydrogen peroxide. The collection also ships carbon neutral, contains no antimicrobials, and meets mindful MATERIALS (mM) program criteria.

However, Designtex’s commitment to sustainability runs deeper than eco-friendly products. Every year the company assesses its operational footprint and invests in carbon reduction projects to reduce or offset their total emissions.

“Through Designtex’s support of 13 innovative emission reduction projects, the company has balanced its total footprint since 2010 and is keeping more than 27,000 metric tons of CO2 from the global atmosphere, while investing in communities across North America,” says Deidre Hoguet, director of applied research at Designtex.

Known for rigorous development of textiles and wallcoverings with reduced environmental impact, Designtex’s upholstery fabrics provide durable, long-lasting alternatives to PVCs.

These are just a few things that we love about the Rider, Tailor, and Wend collection.

Sustainable Materials

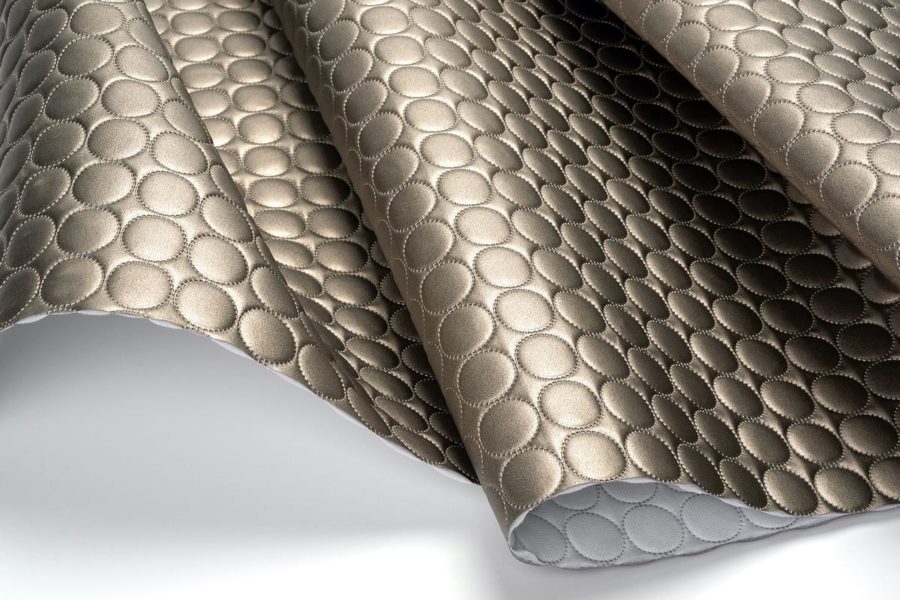

Photo courtesy of Designtex

The Rider and Tailor textiles include 100% polycarbonate polyurethane coated fabrics. While Rider is made with a silicone finish, Tailor’s protective, stain-resistant topcoat finish results in a durable, long-lasting product with easier maintenance.

Using recycled plastic water bottles, the Wend textiles are made from 100% post-consumer recycled polyester. The recycled materials were recovered or diverted from a solid waste stream, either during the manufacturing process or after consumer use. Wend also features a new silicone finish called Supreen.

“Wend is a new technology we are happy to bring to the market called Supreen. It is a polyester fabric encased in a silicone top coat and polyurethane, moisture barrier backing. So you get the look and feel of a woven fabric with all the performance benefits of a coated fabric,” says Sara Balderi, principal designer at Designtex.

Colors and Textures

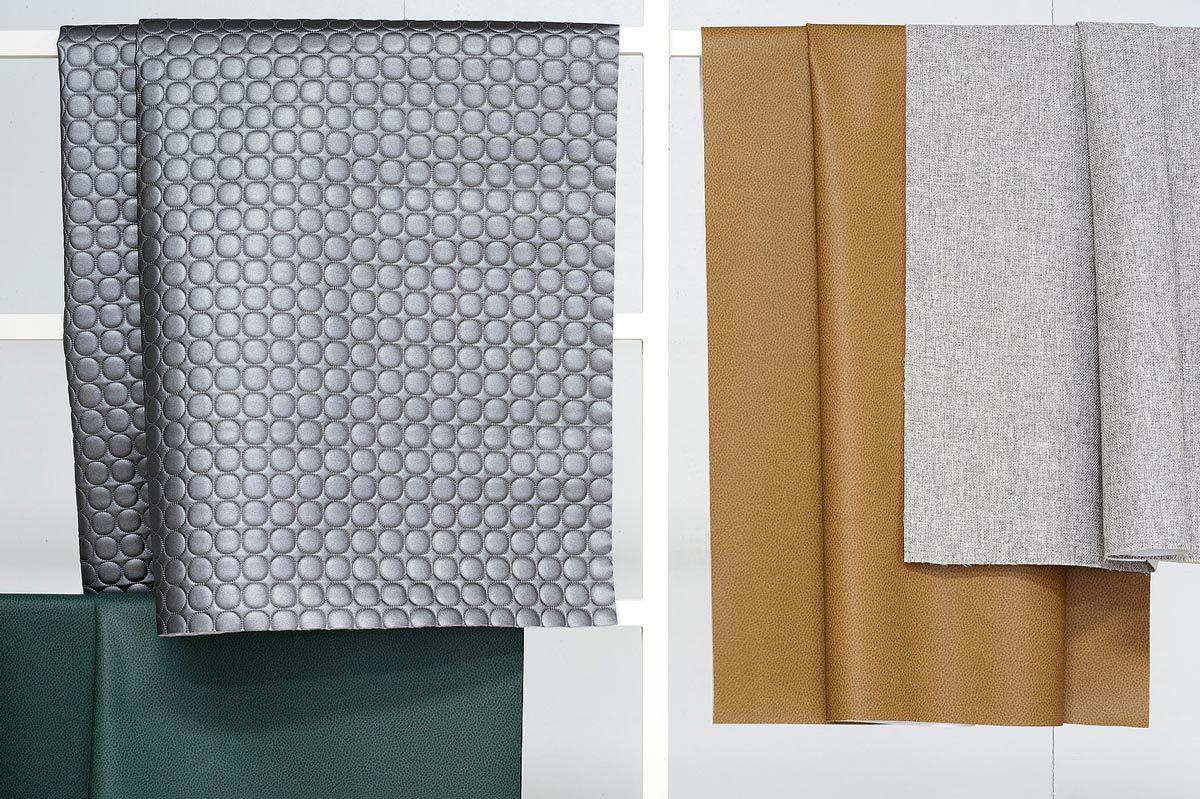

Photo courtesy of Designtex

The Designtex textiles in the Rider, Tailor, and Wend collection include 52 color options and a variety of textures.

With a silicone finish and polyester backing, Rider has the look and soft feel of full-grain leather, Balderi says. However, unlike leather, the textiles are affordable and can be repeatedly disinfected with bleach and other chemical cleaners.

Tailor’s matelassé textiles are dimensional coated fabrics with a smooth surface and circular stitchings for a sleek, minimal effect. Wend, on the other hand, mimics the style of a woven natural fabric and includes a heathered and nuanced surface to create a soft and subtle texture, Balderi says.

Combined with the various textures and patterns, the collection’s many color options can be easily paired with other hues and materials.

Ships Carbon Neutral

Photo courtesy of Designtex

Aligning with Designtex’s overall commitment to sustainability, all three textiles in the Rider, Tailor, and Wend collection are shipped carbon neutral. The emissions produced from the shipping process are offset by Designtex’s ongoing investment in carbon reduction projects.

Designtex also tracks the product shipments from their mill partners and warehouse by CO2 tonnes per mile. To further reduce their carbon footprint, the company aims to consolidate shipments and select low-emitting transportation partners.

“Designtex is committed to improving the material health and transparency of our products,” Hoguet says. “We use our material chemistry knowledge along with sustainability certifications to continually improve our products’ contribution to human and environmental health.”