ASSA ABLOY’s self-powered door operator is earth-friendly from the start.

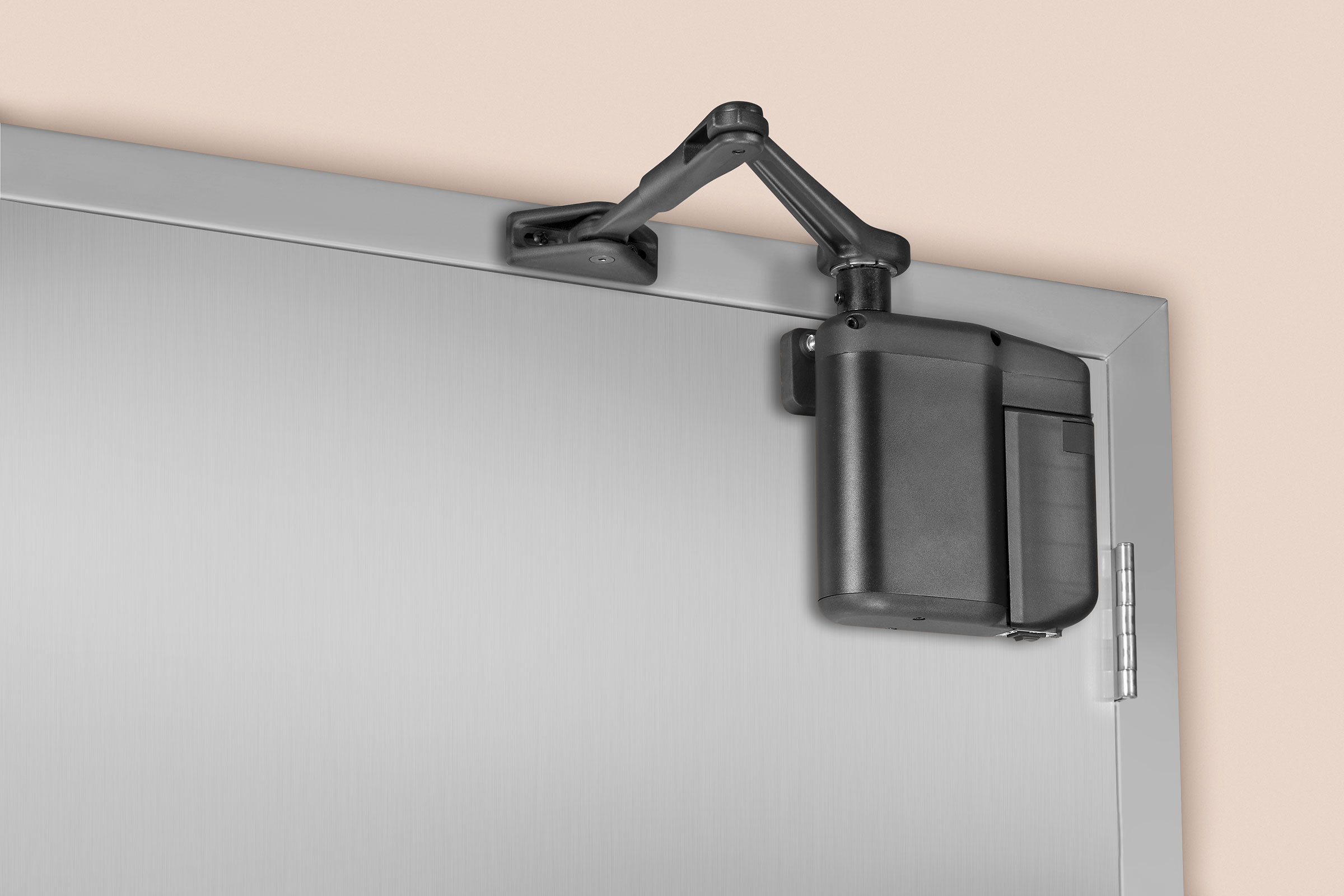

Automatic doors are essential to making a structure compliant with the Americans with Disabilities Act (ADA). For those doors to work, a user has to push a button, which sends an electric signal to a motor, which uses an electric current to swing the door open via an installed door operator unit. Until, that is, Hass invented a door operator called the ADAEZ® Pro, which is now the foundation of the 5800 Series ADAEZ line of low energy door operators manufactured in Monroe, North Carolina, by the Swedish door hardware company ASSA ABLOY.

In common applications, most building occupants will use a door manually. In the case of the ADAEZ Pro, “The energy from those opens and closes, pushes and pulls, is stored in an onboard rechargeable battery within the door operator,” says Amy Musanti, director of sustainable building solutions at ASSA ABLOY. When a person arrives at the door and requires the use of a push-button to open it automatically, the required electricity comes from that onboard battery instead of from the grid. That push button can either be wired or, for even easier installation, triggered by radio frequency.

As long as the door sees at least 80 manual uses each day, and only about 25% of traffic through the door chooses the automatic option, the battery will maintain enough charge for occasional automatic use. A door that would normally be a constant power draw is suddenly up to 100% regenerative.

For situations where a door doesn’t get enough manual use to charge the battery, ASSA ABLOY does offer another 5800 Series ADAEZ model that can be wired using a 24VDC plug in wall transformer. Even then the device only draws less than one watt of electricity to maintain a full charge.

But the sustainable attributes of the 5800 Series ADAEZ don’t end there. Globally the team at ASSA ABLOY is making a concerted effort to reduce the product’s “embodied carbon”—the greenhouse gases that are released through the supply chain, from raw material extraction to product installation. “We haven’t spent a lot of time in the industry as a whole in understanding that,” Musanti says. “Now we have to say, ‘What does it look like when we’re extracting raw materials? When we transport products? When we package them?’”

The 5800 Series ADAEZ is made from recycled materials. It is manufactured in a zero waste to landfill, GreenCircle-certified factory in Monroe, North Carolina. The factory has taken measures to reduce water consumption and boasts a robust recycling program that takes care of all its plastic, styrofoam, cardboard, and paper. Any trash that is generated doesn’t go to the landfill but is instead incinerated. It is equipped with motion and proximity sensors, so lights dim or go dark when they aren’t needed. “It supports ASSA ABLOY’s goal as a good corporate citizen,” said Kenya Moses, general manager of the North Carolina plant.

The plug-in 5800 Series ADAEZ is 91% more efficient, and the wireless 5800 Series ADAEZ is 100% more efficient, according to GreenCircle, as compared to similar products. Photo courtesy of ASSA ABLOY

In another carbon-cutting move, the 5800 Series ADAEZ comes with everything a maintenance staff would need for installation—the operator assembly, the battery, the push buttons, the transmitters—all in one package. “We call it ‘one solution in the box.’ It doesn’t come in four or five different boxes,” Moses says. “The installer isn’t going to have to go back to the shop to order another part.” That saves the maintenance staff time and frustration, eliminates the need for extra packaging, and reduces the resources required to ship extra parts to the user.

ASSA ABLOY has also tried to make the 5800 Series ADAEZ as cost effective as possible. It can be mounted on doors built without headers or transoms, so it’s a convenient solution for older buildings that need to be made ADA-compliant without major renovations. And installation is simple enough for a facility’s maintenance team to install it within a few hours—so there’s no need to hire a contractor. “Many of the customers who need this type of solution don’t have the most generous budgets,” Musanti says. “We need to get away from this idea that a responsible building should cost more. The ADAEZ is meant to be an accessible and sustainable solution.”

ASSA ABLOY is working to have the device certified as a Living Product. The designation, given by the International Living Future Institute, seeks to highlight products that leave a positive impact on the world. Products must be made free of toxins, and the companies that make them must be socially and ethically responsible. “It’s a really positive challenge for manufacturers to see how we can optimize our processes and products,” Musanti says. With the ADAEZ, ASSA ABLOY is certainly pushing the industry in that direction. gb&d