Carpets are a popular flooring solution because they help absorb sound, prevent slipping, and can add a beautiful aesthetic element to any space. In 2019 alone, 19 billion square feet of carpet was sold, and the EPA estimates that each year in the US five billion pounds of carpet is discarded in landfills. That equates to approximately 17 pounds of carpeting per person.

Most commercial carpets are made primarily from finite resources in the form of oil-based plastics that could be recycled. However, only 5% of carpet waste ends up being recycled. Even worse, it takes carpet sitting in a landfill hundreds of years to degrade.

Carpet waste in a landfill. Photo courtesy of Aquafil

About 9% of global CO2 emissions come from built environments, according the the Architecture 2030 report. More emissions are forecasted as the global building supply is expected to double by 2060 to accommodate unprecedented urban growth.

The United Nations reports that the extraction and processing of natural resources accounts for one half of total greenhouse gas emissions worldwide and more than 90% of biodiversity loss and water stress. If the global population continues to grow as predicted, reaching 9.6 billion by 2050, it could require the equivalent of almost three planets to provide the natural resources needed to sustain current lifestyles.

Making eco-friendly carpet choices in projects can help turn the tide. So what options do we have to make more sustainable decisions about the carpeting we use in our projects?

1. Plan for discarded carpets to be recycled.

Recovered carpet can be made into a range of products, including new carpets, textiles, automotive parts, consumer packaging, and composite lumber. Make sure your carpet installation team knows how to pull the old carpet up following recycling guidelines and works with a reputable carpet recycling partner.

2. Look at the materials.

ECONYL® yarn spools at one of Aquafil’s production facilities. Photo courtesy of Aquafil

When selecting the eco-friendly carpet for your project, check the materials used. Is it made with low VOCs and low-emitting adhesives? Does it include any recycled content, and is there an end-of-life take back program from the manufacturer? Many manufacturers that are focused on sustainability offer carpet take-back programs that reclaim carpeting and have pathways to reuse it. Some manufacturers include Interface, Mohawk, Shaw, and Milliken Carpet.

3. Research eco-friendly carpet standards.

Check the carpet label to make sure it’s been tested by the Carpet and Rug Institute’s (CRI) Indoor Air Quality testing program and has passed the CRI’s standards for low emission. The CRI Green Label Plus (GLP) ensures that you are purchasing among the lowest emitting carpet, adhesive, and cushion products on the market. Another credible certification to watch for is Cradle to Cradle Certification, which is a science-based standard for circular products.

4. Seek out carpet made with either natural or recycled renewable fibers.

Great natural carpet material options include seagrass, jute, coir, organic cotton, organic wool, and bamboo. The materials used to create these carpets are not only biodegradable, but they also don’t require a lot of fertilizer and pesticides to produce.

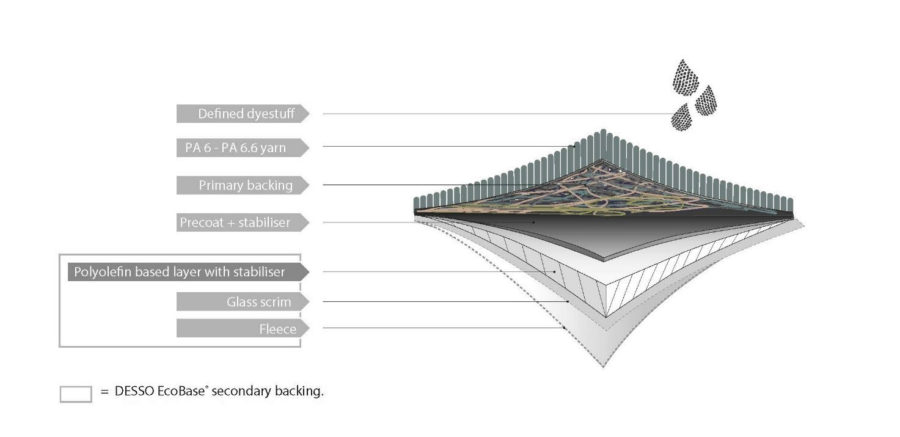

The content of the carpet backing matters, too. More and more carpet manufacturers are using natural materials for backing including nonsynthetic latex, untreated wool, or camel hair felt. Carpet backings that are sewn on or glued using natural, nontoxic adhesives are healthier choices than those with adhesives that emit VOCs.

Recycled carpets are another eco-friendly option. Rather than making carpet from petroleum and other fossil fuels, some carpet manufacturers use both pre- and post-consumer plastics like polyethylene terephthalate (PET) bottles or industrial scraps. PET carpet, sold under brand names like Resistron and Permalon, is made from 100% recycled plastic beverage bottles and can be down-cycled into insulation or furniture stuffing when it wears out.

Courtesy of Desso

Carpet manufacturers are also using other regenerated materials, such as ECONYL® regenerated nylon, which performs exactly the same as brand new nylon but can be recycled, recreated, and remolded again and again. This means new products such as eco-friendly carpet can be created with ECONYL over and over again without having to extract or process nonrenewable resources. ECONYL even reduces the global warming impact of nylon by up to 90% compared with the material from oil. Aquafil, the maker of ECONYL, is also building its carpet recycling network with several centers active in the US. Each facility has the capacity to collect and treat 36 million pounds of carpet each year, making a sizable dent in the waste stream.

More and more owners are seeking spaces that are sustainable and healthier for occupants. It is our responsibility to build a better future. We must strive to preserve the integrity of our planet for future generations. It’s not only the right thing to do—it’s the smart thing to do.

Focusing on eco-design and sustainable materials can provide firms that do it right with a competitive advantage. Interior designers and architects should take the lead to promote sustainable practices to differentiate their firms from the competition that is lagging behind. Carpeting is a key area where we can make a difference and convert what was once damaging waste into a circular, sustainable supply chain.