Story at a glance:

- The Biden administration has set a net zero emissions goal by 2050. Some states have even more aggressive goals.

- Being electrification-ready can help residential and commercial property owners meet new energy standards while reducing energy use and spending and improving air quality.

- Aeroseal reduces leakage in the duct system by 90%. That translates into approximately 20% energy savings in homes.

To meet current net zero emissions goals, greenhouse gas emissions will need to be drastically reduced across all sectors of our economy—from transportation to manufacturing to how we heat, cool, and use energy in our residential and commercial buildings.

Energy in residential and commercial buildings represents nearly one-third of all greenhouse gas emissions today. “Buildings are a big part of the puzzle,” says Maggie McCarey, head of policy and market development at Aeroseal, a leader in duct and envelope air sealing technology. “They produce about 30% of the greenhouse gas emissions across the US right now, so to deliver on these clean energy and climate goals we’re going to need to decarbonize the building sector.”

This requires transitioning off of fossil fuels and over to renewable, clean electricity. That translates to moving away from traditional heating sources like gas and propane and moving toward electricity that is produced with wind and solar power. “We’re starting to see government incentives for electrifying homes and businesses as a result,” she says.

To make this transition she says the industry needs to focus on reducing overall energy usage and improving energy efficiency by reducing the load of buildings—a focus that’s known as “electrification-ready.” We recently talked with McCarey for more insight on how to reduce energy usage at a time of such great need.

What does it mean to be electrification-ready?

There are two categories of investments when it comes to being electrification-ready. The first is energy efficiency—reducing the load of these buildings to make electrification (i.e., going electric) easier. This includes things like weatherization measures, insulation, and duct sealing.

The second category includes overcoming the barriers residents or businesses will face when they actually replace fossil fuel appliances with electric appliances like heat pumps. These barriers include electric panel upgrades to enable the transition from gas to electric in a home.

What are some of the benefits of making a building electrification ready?

The measures you take to reduce and eliminate air leakage, including using Aeroseal air sealing and improving your insulation, are going to result in reduced energy usage, which means lower utility costs.

There are also benefits in indoor air quality and comfort. If you reduce drafts in the building envelope and ductwork you’re going to be more comfortable in your home. And as we shift away from burning fossil fuels and toward electrification, we’ll start to see the indoor air quality benefits of that as well.

Does the age of the building make a difference?

Yes, it does. Building codes have become more efficient over time, so older homes generally are much leakier and much more inefficient than newer homes. Modern homes built in the last 10 or 20 years are much more efficient than homes built in the ’70s, ’80s, or even before that.

Since older homes are much leakier, there’s greater opportunity and benefit for energy efficiency in those homes. It’s really critical that we address those older buildings because those are some of the bigger emitters and often have more barriers to electrification.

If a house is hot upstairs and cold downstairs, can electrification help?

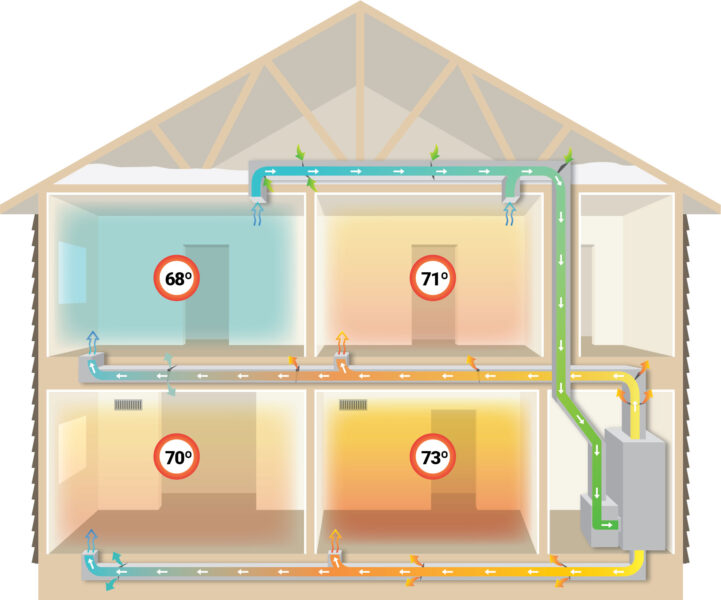

Image courtesy of Aeroseal

This is one of the benefits of our duct sealing technology. Often what’s driving some of the temperature differential between areas of a home is because the duct system is leaking conditioned air. What we’ve seen is duct systems can leak out 25 to 40% of the conditioned air your heating or cooling system creates. That air that’s leaking out isn’t getting to the place where you want it to go. When we seal the duct systems we see much more consistent temperatures and much more improved comfort in the home because you’re getting that air where it needs to go.

Air sealing and insulation of the building envelope can help with being electrification ready as well. Imagine, for instance, you’re sitting next to a drafty window. Sealing the envelope—the entire home structure rather than just the ductwork—is going to definitely improve the indoor temperature and reduce drafts.

How does Aeroseal help existing structures become electrification-ready?

Our technology has revolutionized and created a new way for sealing leaky duct systems in existing buildings. If you can imagine a building with a duct system that brings hot and cold conditioned air through the home, it’s really impossible in existing buildings to have access to that entire duct system. Those ducts are behind the walls; they’re in places where you can’t reach. Traditionally duct sealing requires finding the ducts you have access to and using tape or paint-on sealant to seal up the ducts. What that doesn’t do is get to the ducts you’re not able to access.

We pressurize the duct system and blow in micro-sized particles of a water-based sealant like a fog. Those particles find all the cracks and leaks within the duct system and seal them, so we’re sealing ducts from the inside out. We’re able to reduce leakage by 90% on average, which translates to about a 20% energy savings for the average home.

If your house is heated with gas, using Aeroseal will immediately help reduce gas heating bills. But if you put a heat pump in that system, it becomes really important you’re not blowing air from that heat pump into a leaky duct system and that you’re getting heat to the places you want it to go. Duct sealing helps the heat pump perform at a high efficiency. Aeroseal also helps reduce the energy load as a home transitions from gas to electric, reduces overall costs, and improves comfort.

What is involved with envelope sealing?

With the envelope we’re primarily focused on new construction. Instead of pressurizing and blowing our sealant into the ducts we pressurize and blow our sealant into the entire home. When a new home is built and the drywall is put up, we’ll go in and blow the fog of sealant into the entire pressurized home. That way you’re sealing all the cracks in your building envelope or building shell. The sealant will seal around your windows, doors, and other areas known to be leaky. That process takes about four hours, including two hours setup time and about two hours of sealing time.

Do you get better efficiency with new construction?

Yes. One of the big benefits of our technology in new construction is the ability to get to lower levels of leakage in the building envelope in less time than caulking. The second major benefit is that everything is software-enabled. As we’re pressurizing the system we’re taking multiple measurements, including measuring leakage before we start sealing; then during the seal we can monitor how well the sealant is actually closing up the leak. At the end of the process you know you’ve achieved the reduction you were trying to achieve.

That data is really important for new construction, especially as new codes come into place that mandate builders meet certain levels of air sealing requirements. Also, a lot of builders are looking at building to EPA ENERGY STAR standards. As we start to see buildings become more efficient this is a really reliable way to meet code requirements.

Do you have to leave home when this is being done?

For Aeroseal duct sealing you don’t need to leave the home; Aeroseal sealant is safe. It’s nontoxic, has low volatile organic compounds (VOCs), and we’re Underwriters Laboratories (UL) listed. If someone wanted to leave while their ductwork was being done, they could; the sealing process itself, when you are blowing the sealant into the system, is only 25 minutes. The duct sealing process in total is about four to five hours. Most of that is setup.

For envelope sealing the home must be empty. In new construction generally there is no one in the home. Also, the sealant dries fast, so there are no problems with off-gassing once people re-enter.

What are some of the tax credits available?

The Inflation Reduction Act expanded and extended tax credits for energy efficiency and electrification. For existing homes the 25C tax credit offers up to 30% of the cost of a tax credit, or up to $1,200 for energy efficiency measures in your home. Aeroseal’s duct sealing qualifies for that. There is also a $2,000 tax credit for air source heat pumps or other electrification measures that homes may be implementing as well.

With new construction the Inflation Reduction Act expanded and extended the tax credit for building energy-efficient new construction. It offers $2,500 for homes that are built to EPA ENERGY STAR standards, and up to $5,000 for homes that are built to a program run by the US Department of Energy called Zero Energy Ready Homes, which includes higher efficiency and also renewable ready requirements.

In addition to tax credits $8.8 billion in home energy rebates are coming up. Those programs are going to be run through the states and will include incentives targeted at helping low- and moderate-income customers and disadvantaged communities invest in energy efficiency and electrification. Depending on the state we expect those rebates to be phasing in starting in 2024. There’s also existing funding available through federal weatherization programs and local utility energy efficiency programs.

How long does being electrification-ready last?

Most of the measures we’re talking about are very long-lived. With duct sealing, for example, we’ve tested our technology to 40 years. It’s not something you need to redo. Being electrification ready is less about an annual assessment and more about having a decarbonization plan for your home or building—an assessment of what you need to do to be able to make your home high efficiency and electrification ready, and then creating a plan to get there.