Water restrictions are becoming more and more prevalent in building codes and municipalities, making building material selections more limited. But the government has also provided funding through LEED programs and breaks on different taxes. Navigating the newer water restrictions can be tedious and frustrating, and funding has been scarce with the exception of the newest infrastructure bill.

Because of the fast-acting restrictions, manufacturers have been diligent to create products that can keep up with the regulations and still maintain performance expected by the end uses.

Image courtesy of Niagara

Over the years, the technology has improved from the original high-efficiency toilets (HETs) that created a bad reputation for conservation. The poor performance resulted in creative solutions like adding brick in the tank to raise water levels just to bring the toilet to an acceptable performance level. These poor-performing models caused architects and engineers precious time, money, and sanity over the ’90s and early 2000s and developed distrust in HETs that has persisted over the past two decades.

Thankfully, we have advanced in the 30 years since the government mandated that new construction projects utilize toilets with 1.6 GPF or lower, because now we are seeing the mandate move to 1.28 GPF and lower—with 1.1 or even 1.0 GPF coming quickly behind. Through advanced research done by PERC, IAPMO, and the EPA, some HETs have become the best performing fixtures on the market.

When considering how to choose a high-efficiency toilet, it has to hit five major pillars: drain line carry, flush technology, certifications, warranty, and overall design.

Drain-Line Carry

Photo courtesy of Niagara

Drain-line carry is the most important consideration when looking at HETs. In the past, plumbing backups have been a major issue when an HET was retrofitted, especially at a multifamily or a commercial property. Issues created by older pipes, poor infrastructural design, and lack of options for different flush technologies just inflamed the distrust that plumbers had in HETs. Even though IAPMO and PERC have created and run tests that prove that HETs can carry waste to the sewage lines just as well as a traditional 3.0 GPF or higher toilet, architects and engineers have been wary to spec them for new projects.

Because of these issues, manufacturers like Niagara worked tirelessly to create a solution that provided a high-performing but highly water-efficient toilet that passes the tests performed by IAPMO for drain-line carry.

Retrofitting Properties and Remodels

Often there are concerns of drain line corrosion in older properties where iron piping or galvanized pipes are being used. While this is a legitimate concern, and a qualified inspector should look at a plumbing system before installing new products in an outdated environment, the issues stem not from the amount of water being used, but from the ineffectiveness of the materials used when making older drain lines.

It’s important to consider that when you install a low-flow toilet in a multifamily or commercial property, drain line water flow is not exclusive to the toilet. Showers and faucets contribute to water flow within a property and assist with washing waste away, providing more than enough water to push down sediment. Your toilet will be working within a plumbing system, not as an isolated fixture.

New Construction

New construction should not have the same concerns as an older building, but it does come with its own host of concerns. Thanks to PVC piping and other updated materials, drain line carry can go much more smoothly in a new building, but you want to be sure that the toilet you specify for the project can still push waste to the sewage line no matter how large or tall the property is.

IAPMO requires that all toilets pass a series of drain-line carry tests a third party performs before being passed for sell in the United States. Specifically, HETs have to comply with ASME A112.19.2 / CSA B45.1 standards, which dictate that for the drain line carry, flush media must travel at least 40 feet. Regardless of how much water is being used, if even Niagara’s The Original™ 0.8 GPF can move waste upwards of 60 feet, then any HET on the market should be able to do the same. To be sure you’re not going to have a problem reaching the sewage lines, you may want to also consider the flush technology the toilets you’re specifying have.

Flush Technology

Image courtesy of Niagara

Currently, there are three flush technologies available on the market: traditional gravity, pressure-assisted, and vacuum-assisted.

Gravity-Fed Technology

Traditional flush technology has been around for nearly 250 years and utilizes a flapper or a gravity tip bucket; it’s probably the most common type of toilet. Because it’s traditional, it’s typically the least expensive of the three up-front. The money saved up-front on toilets using this technology is spent on upkeep, maintenance, and rising utility costs. For example, the most common part that needs to be replaced is the flapper, which when not repaired, causes constant water leaks and running toilets.

Vacuum-Assist Technology

The newest technology is a flapper-less toilet known for its quiet, efficient flush. Because of their advanced designs, vacuum-assist toilets use ambient air to force water through the trapway with nearly half as much water as the other two technologies. This modern flush is the most water-efficient while offering excellent performance.

Pressure-Assist Technology

With a vessel that sits inside of the tank, a pressure-assisted toilet is great for commercial applications and high-traffic areas. The vessel utilizes air pressure to force water through the toilet’s trapway and can be characterized by its loud, fast flush.

You will want to choose the flush technology based on your property type and specific needs. If you have a property that is a blend of commercial and residential, say an apartment complex that sits on top of retail, or a senior living facility, you may want to use a mix of technologies.

There is not a one size fits all solution, which is why you should go with a manufacturing brand that offers all three technologies. This way you can have flexibility without having to use multiple vendors. When looking through different manufacturers for an HET, you also need to consider the certifications their products carry. These are proof that their product can perform as promised.

Certifications and Compliance

Photo courtesy of Niagara

There are two major certifications that HETs should have along with models that are ADA compliant—the EPA WaterSense® Program certified and the Maximum Performance Premium (MaP) label. Not only do these certifications prove performance, but they help secure LEED points that can win builders grants through government funding. With the government water restrictions swiftly moving across the nation, architects and engineers can trust HETs to get the job done.

The EPA WaterSense Program mandates water usage of plumbing fixtures to drive innovation, conservation, and elimination of waste. Apart from following the requirements from the American Society of Mechanical Engineers (ASME) and having a toilet flush capacity of 1.28 GPF or less, WaterSense certified toilets must also pass a flush performance test. This test, performed by a third party, requires that the bowl clears test media in a single flush. If the bowl is not completely clear from a single flush 80% of the time, it fails the test. To receive the WaterSense certification, the water-saving toilet must be low-flow and high-performing.

The measurement of water-efficiency in toilets goes beyond GPF. Check to be sure that your toilet of choice also carries the MaP Premium label. MaP is an independent testing program that tests a water-saving toilet’s ability to flush a minimum of 350g of waste (12.3oz). The MaP Premium certification goes so far as to require that a single flush must clear the bowl of at least 600g (1.3lbs) of waste at a 1.1 GPF. This certification marks the toilet as a fixture that is highly efficient with a flush powerful enough to reduce clogs and callbacks.

ADA Compliance

Photo courtesy of Niagara

Most laymen don’t usually realize that a toilet has a lifespan of about 50 years if not longer. A lot of things can happen in half a century, and it’s good practice to install a toilet that is compliant with the Americans with Disabilities Act (ADA). Everything from height to flush controls matters. Below are the highlights that make an ADA compliant toilet.

Seat Height

The height of the toilet bowl with the seat attached must be 17 to 19 inches. This measurement should be from the floor to the top of the seat and can be helpful for wheelchair transfers or even for people who have a hard time standing from a sitting position.

Operation

For a toilet to meet ADA requirements, the force to activate the operable parts (handles, levers, buttons, etc.) needs to be less than five pounds. Most ADA-compliant toilet manufacturers will also provide options of where the operable parts are positioned to help make selections easier for people with disabilities.

The operable parts must also be completely unobstructed by the user. Operable parts must be within a vertical distance of 15 to 48 inches and a horizontal distance of 10 inches at the max.

Flush Controls

The flush controls also need to be hand-operated or automatic. Flush controls need to be located on the open side of the toilet. For center position push buttons, the controls must be symmetrical to either side of the toilet. Most manufacturers will provide options of where these controls are located on the toilet, meeting this requirement.

With the age of mortality growing ever higher, aging in place is a big conversation point when speaking about appliances and fixtures in residential spaces. ADA compliance is extremely important for individuals investing in homes and living spaces because they understand that they will be aging along with the resident. Talking about aging in place brings up the issues of warranties and what the warranty on an HET should look like.

Warranties

From the time we’re out of the diapers to the time we’re back in diapers, it’s said we sit on a toilet for approximately three years of our lives. A toilet that is backed by a robust warranty provides peace of mind for both professionals and property owners. Most toilets only have a warranty for up to a year or maybe five years after purchase, but more recently there have been warrantied for as many as 10 to 15 years.

For example, most Niagara toilets come with a warranty of at least 15 years. Niagara’s UHETs™ are created with parts that don’t wear out, even if it’s used as often as the average adult tends to use a toilet—about 2,500 times a year. Even if a part does wear out, Niagara sends out a replacement at no cost to the user.

Finding manufacturers that believe in their products is key to specifying the right fixtures in your projects. You should know that they have ultimate confidence in their product’s performance and can feel secure in the choice you’ve made, no matter if it’s five, 10, or even 15 years after the project has been completed. This all begs the question, just because it conserves water and can perform beyond standards, does that also mean that it’s ugly? The short answer is no.

HET Design

Just because an HET can save more than 50% of water while functioning just as well as traditional toilets does not mean that they’re ugly to look at. HETs can come in a variety of options from round to elongated bowls, with several handle positions and options and modern styles. One of the more modern-looking toilets on the market is Niagara’s One Piece. One of the biggest compliments Niagara has received on these toilets is that they’re super easy to install but they’re even easier to keep clean.

Additionally, most new homeowners want a say in their home’s fixtures, and although water conservation and eco-friendliness are important, so are the overall design and look.

Case Studies

Photo courtesy of Niagara

We can say that HETs work until we’re blue in the face, but without real-world examples, it’s hard to believe the word of a manufacturer. Luckily, we have case studies showcasing just what Niagara’s HETs can do for properties of all types.

The Girard Street Apartments

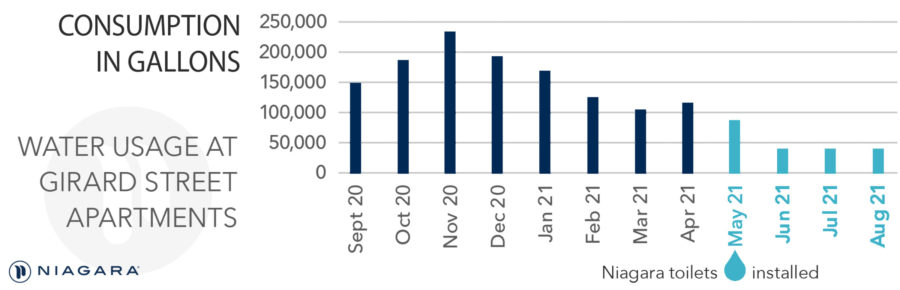

Image courtesy of Niagara

To offer an affordable housing option for residents ages 55+, apartments are required to be ADA compliant to fit the needs of their tenants. The existing toilets in The Girard Street Apartments were replaced with an Ultra-High-Efficiency model from Niagara. The Original utilizes Niagara’s patented Stealth Technology® and comes in an elongated shape that is best for comfort and uses 0.8 GPF instead of 1.6 GPF.

By just replacing toilets, the property was able to realize a 77% reduction in consumption and a 73% decrease in water and sewer costs. These reductions resulted in a 375% monthly ROI for the owners, who were so satisfied with Niagara’s Original and Aqua Savers‘—a company that specializes in retrofitting water-efficient products in multifamily properties—services, that they have retrofitted several other properties and are seeing similar results.

Holiday Inn Express Hotel & Suites

After AMI opened a new Holiday Inn Express Hotel & Suites in Surprise, Arizona they were introduced to Niagara’s Stealth Toilet and its water- and energy-saving properties by Del Johnston, owner of The Marketing Pros in Scottsdale.

The presentation demonstrating the quiet flushing action, one-button flush, water-saving, and the 100% cleaning action of the bowl convinced them to retrofit the entire property. Johnston also went the extra step in arranging for the complete professional installation and removal of all the older 3.5 GPF toilets.

Since the Stealth installations, they are using 55% less water than with the previous toilets. Best of all, they have received no complaints from hotel guests as the Stealth Toilet continues to perform quietly and flawlessly. Mike Patel, the owner of Holiday Inn Express and Suites, was so pleased with the results that they have installed 100 Stealth Toilets in a second property. Describing his experience with the second property, Patel said the HETs provide the same performance, quality, and water savings.

Jane Apartments

Jane Apartments, a 52-unit, three-story property, was originally built in 1937. Aqua Savers replaced the old, high flow toilets with Niagara’s The Original model that flushes at 0.8 GPF. With this change alone, the property was able to realize a 47% reduction in consumption and a 53% decrease in water and sewer costs, saving them nearly $20,000 every month.

With all of the updates made to HETs and the proof of success, it’s obvious that HETs will be gaining popularity again soon. Beating out the outdated notion that HETs are not reliable or a good fit for older properties, the new and modern models offer substantial benefits to architects and builders across the industry.