Story at a glance:

- New 74-month findings offer fresh insight into long-term membrane performance.

- GCP continues to advance its below-grade waterproofing portfolio with a focus on evolving customer needs.

Ensuring a waterproofing membrane performs for the full service life of a structure, not just at installation, remains an essential requirement for modern below-grade construction. Standard hydrostatic testing like ASTM D 5385 evaluates only fresh, non-aged samples and does not represent the real-world exposure conditions structures face over decades.

To address this GCP developed the Lateral Water Migration Resistance (LWMR) test by modifying ASTM D 5385 to include a membrane breach. This more accurately reflects whether a waterproofing system can stop water from moving between the membrane and structural concrete under long-term hydrostatic pressure.

Why Lateral Water Migration Resistance Matters

LWMR measures a membrane’s ability to restrict water movement in the event of a puncture or installation defect.

Without this capability, bypassed water can travel unchecked beneath the membrane, leading to leaks far from the original breach and resulting in costly, intrusive remediation.

Long-Term LWMR Program: PREPRUFE® 300R Plus (2019–2025)

To validate the long-term performance of the enhanced PREPRUFE® 300R Plus system, featuring ZipLap™ technology, a multi-year immersion program was initiated in 2019.

Testing was prepared and conducted under the supervision of representatives from KIWA BDA testing lab from Gorinchem, Netherlands. KIWA BDA is a globally recognized testing, inspection, and certification institute of the building envelope.

Representatives from KIWA BDA were present during sample preparation and scheduled periodical water pressure tests.

This supervision ensured independent verification at every critical phase of testing, from casting the concrete onto the membrane to each scheduled hydrostatic pressure evaluation.

How the Test was Conducted

- Concrete blocks were cast directly onto PREPRUFE 300R Plus.

- A deliberate breach was created in each membrane sample to replicate a realistic puncture scenario.

- All specimens were fully immersed in controlled water tanks for the duration of the study.

- Hydrostatic pressure tests followed the AFTES-modified ASTM D 5385 procedure.

- At 1, 6, 12, 18, 24, 30, 36, 48, 60, and now 74 months, three random samples underwent pressure testing.

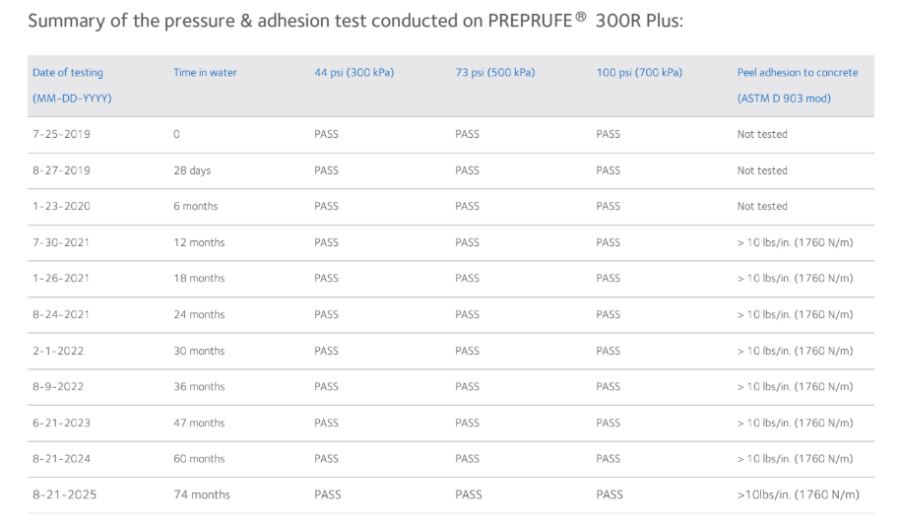

Results Through 74 Months: No Leaks, No Migration, Full Bond

All samples passed all pressure levels (44, 73, and 100 psi). At each interval—from month 1 through month 74—no leaks occurred, and no lateral water migration was observed.

Every specimen remained fully bonded around the breach, demonstrating PREPRUFE’s ability to maintain a continuous bond even after more than 6 years of continuous water immersion.

Why These Results Occurred

PREPRUFE membranes prevent this failure mechanism because of their continuous, intimate adhesive bond to concrete. When concrete is cast against PREPRUFE, its proprietary adhesive chemistry forms a permanent connection to the slab. If a breach occurs the adhesive bond blocks water from traveling laterally, maintaining waterproofing continuity.

Independent testing confirms PREPRUFE membranes resist lateral water migration at 231 ft (100 psi) hydrostatic pressure even after long-term immersion.

Peel Adhesion Performance: Stable Beyond the Published Values

Beginning at 12 months, each sample was also tested for “Peel Adhesion to Concrete as per ASTM D 903.” At every interval through 74 months, adhesion consistently exceeded more than 10 inch (1760 N/m), higher than published baseline performance.

This confirms that PREPRUFE maintains long-term adhesion despite extended exposure to water.

Updated 2025 Test Table

Chart courtesy of GCP

Additional Adhesion Studies

PREPRUFE membranes have also been evaluated under harsh chemical and environmental exposures, including BTEX solutions and high-pH immersion, with no meaningful reduction in bond strength. These worst-case conditions are unlikely to be encountered in real field installations but further validate the system’s durability.

Summary

Photo courtesy of GCP

While standard ASTM D 5385 testing examines only a fresh specimen over a few hours, PREPRUFE 300R Plus has now been tested in significantly more demanding conditions, over 6 years of continuous water immersion with independent KIWA oversight.

Through 74 months, PREPRUFE 300R Plus has maintained:

- Zero leaks

- Zero lateral water migration

- Stable and high adhesion

- Hydrostatic pressure resistance up to 100 psi

These extended findings provide architects, engineers, and specifiers with new long-term data that can inform below-grade design decisions and material evaluations.

Alongside this long-term testing, GCP continues to advance its below-grade waterproofing portfolio by focusing on evolving customer needs. New offerings like PREPRUFE® Liquid Flashing for simplified pre-applied detailing and PERM-A-BARRIER® Ultra Wall Membranes and Flashing for high-temperature applications, demonstrate this commitment.

The lineup now also includes PREPRUFE® SCS Plus, engineered to withstand the force of shotcrete placement on foundation walls. Additional next-generation solutions are in active development. Together these enhancements reinforce GCP’s ongoing investment in proven technologies, long-term durability, and customer-focused innovation.