Over the past 25 years, working as both a consulting engineer and a business development manager for commercial construction, I have seen the building industry evolve in so many exciting ways. We have progressed from 2D hand-drafting to 7D building information modeling programs; from design-bid-build to collaborative integrated project delivery; and from basic, independent HVAC approaches to innovative, holistic solutions like radiant heating and cooling systems that provide optimum thermal human comfort and health while reducing energy usage.

So how does the commercial industry continue to advance the mission of improving building performance while trying to meet time, budget, and resource constraints? Thankfully new technologies are offering alternatives to help professionals find that perfect balance of high-performance design and productivity.

One of these such technologies is PEX. An acronym for cross-linked polyethylene, PEX pipes are a sustainable, flexible, durable, and cost-effective polymer piping product for domestic water, hydronic distribution, and radiant heating and cooling applications for both residential and commercial applications.

Originally developed in 1968 by German inventor Dr. Thomas Engel, PEX first hit the European market in the early 1970s and later came to North America in the mid-1980s. Its incredible durability and cost-effectiveness quickly gained popularity with the residential construction market. Throughout the past two decades, it has grown to become the most-installed plumbing piping product for residential new construction, beating both copper and CPVC combined.

While PEX has had enjoyed a decades-long run in the residential sector, the commercial world has been slower to adopt the technology, with some believing that metals are superior to polymers for rigorous commercial building design. But as demands have increased for value-engineered projects over the past decade, PEX has come to the forefront.

With an offering in sizes up to 4 inches, its use in commercial applications is challenging traditional copper, steel, and CPVC materials that have dominated the commercial building industry for the past century. Add to that the current focus of sustainable building practices, and PEX is proving to be the best alternative to meet all aspects of commercial building design and construction.

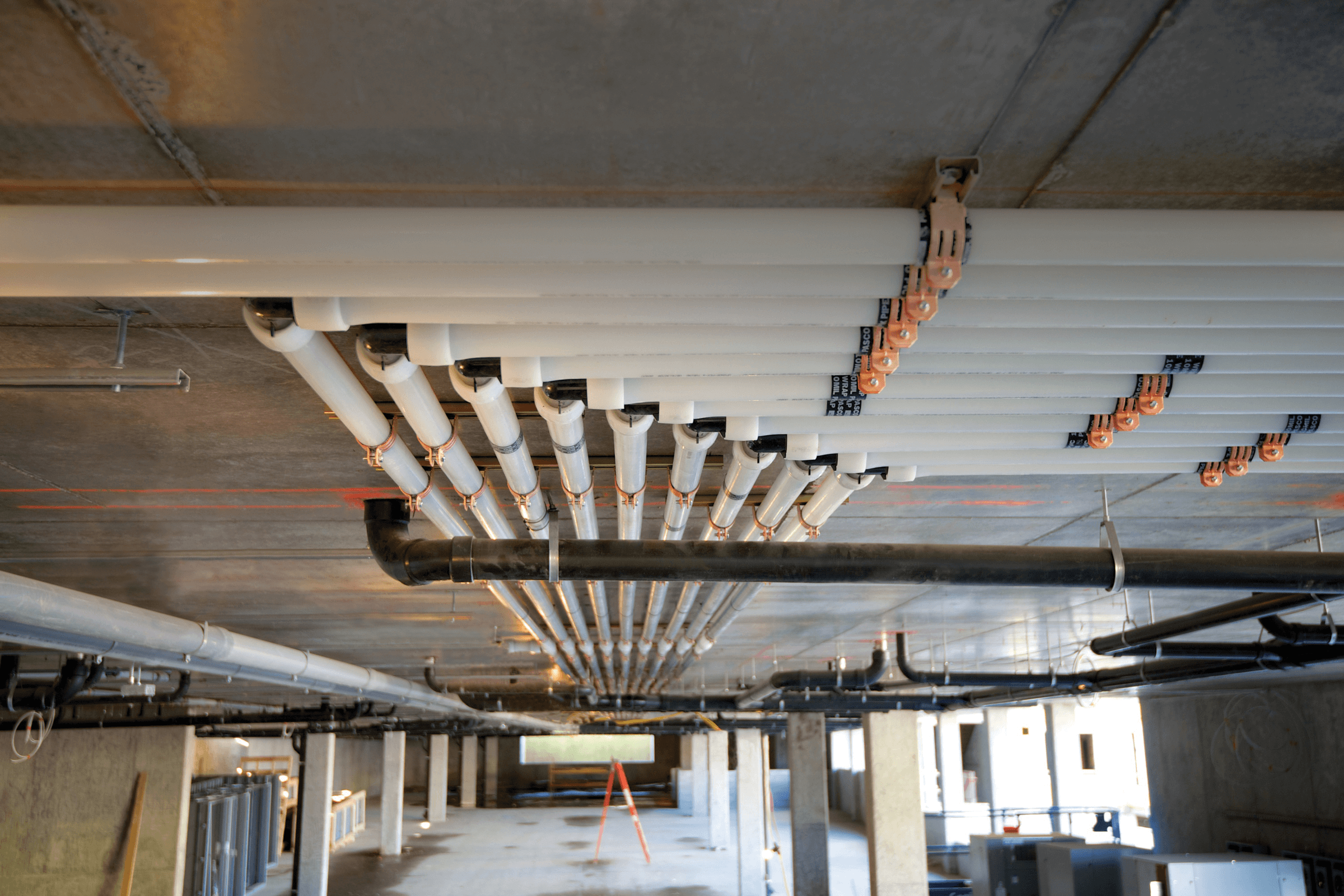

The Pier 15 Exploratorium project in San Francisco uses PEX embedded in a concrete slab to circulate water from the San Francisco Bay as a heat sink and source for chilled water. Photo courtesy of Uponor

How is PEX More Sustainable Than Other Piping Materials?

As PEX use in construction projects increased over the years, many started asking whether PEX pipes are sustainable. So in 2008 the Plastic Pipe and Fittings Association conducted a life cycle inventory research project, analyzing the production and use of installed residential piping systems. In a June 2008 report published by Franklin Associates, the study showed that PEX pipes were the most sustainable solution compared to ABS, CPVC, PVC, polyethylene, and copper. To build on that research, in 2011, the Plastic Piping Education Foundation commissioned research that assessed the environmental profiles of several plastic and metal pipes used in three types of piping applications in residential buildings.

Then in 2016, the Journal of Cleaner Production published a report based on the life cycle assessment comparing the economic and environmental performances of PEX and copper pipes over the life cycle of a student housing project in Lancaster, Pennsylvania. The results of the analysis indicated using PEX instead of copper piping systems would considerably reduce the total cost of the building up to 63% over its life cycle while reducing the carbon dioxide emissions by approximately 42% and lessening the negative effect of environmental impacts to land, water, and air.

Add to that the research conducted by the European Plastic Pipe and Fittings Association, which took into account factors such as exhaustion of natural resources, emissions from manufacturing processes, over-fertilization of water and soil, global warming, ozone-layer depletion, and photochemical oxidation.

All these reports came to the same conclusion: When compared to other piping materials, PEX pipes are the most sustainable choice. It has lower environmental impacts during manufacturing compared to copper because it reduces manufacturing, transportation, and disposal burdens. Plus the energy consumed and overall impacts from manufacturing PEX pipe using common, low-temperature extrusion processes is a clean, low-impact operation.

Compare that with copper. The process by which it is mined, refined, transformed into products such as pipe, and then used is very energy intensive. Manufacturing copper uses a great deal of nonrenewable energy during its lifetime, and copper piping systems have a shorter lifespan compared to PEX because of the corrosion, pinhole leaks, and scale buildup that can happen over time.

Over the past two decades, PEX has grown to become the most installed plumbing piping product for residential new construction, beating both copper and CPVC combined. Photo courtesy of Uponor

How Do PEX Pipes Help the Environment?

I’m sure some of you are wondering how a plastic product like PEX that uses a raw material derived from nonrenewable resources, such as natural gas or crude oil, be a good choice for the environment.

Well, consider this. When taking into account all the alternative uses for crude oil and natural gas, such “feed stocks” are far better off employed for the manufacture of long-lasting durable goods like pipe, rather than single-use, disposable plastic products—such as water bottles, utensils, straws, and packaging—or burned up in single-use applications, such as gasoline or diesel fuel for vehicle engines.

What about the recyclability of PEX? Although each PEX manufacturer has different methods for minimizing their scrap waste, I can say for my company, Uponor, that we recycle 99% of our scrap and repurpose it as filler for other products or transform it via a clean incineration process to extract stored energy that provides heat.

Sustainable Piping Solutions with PEX

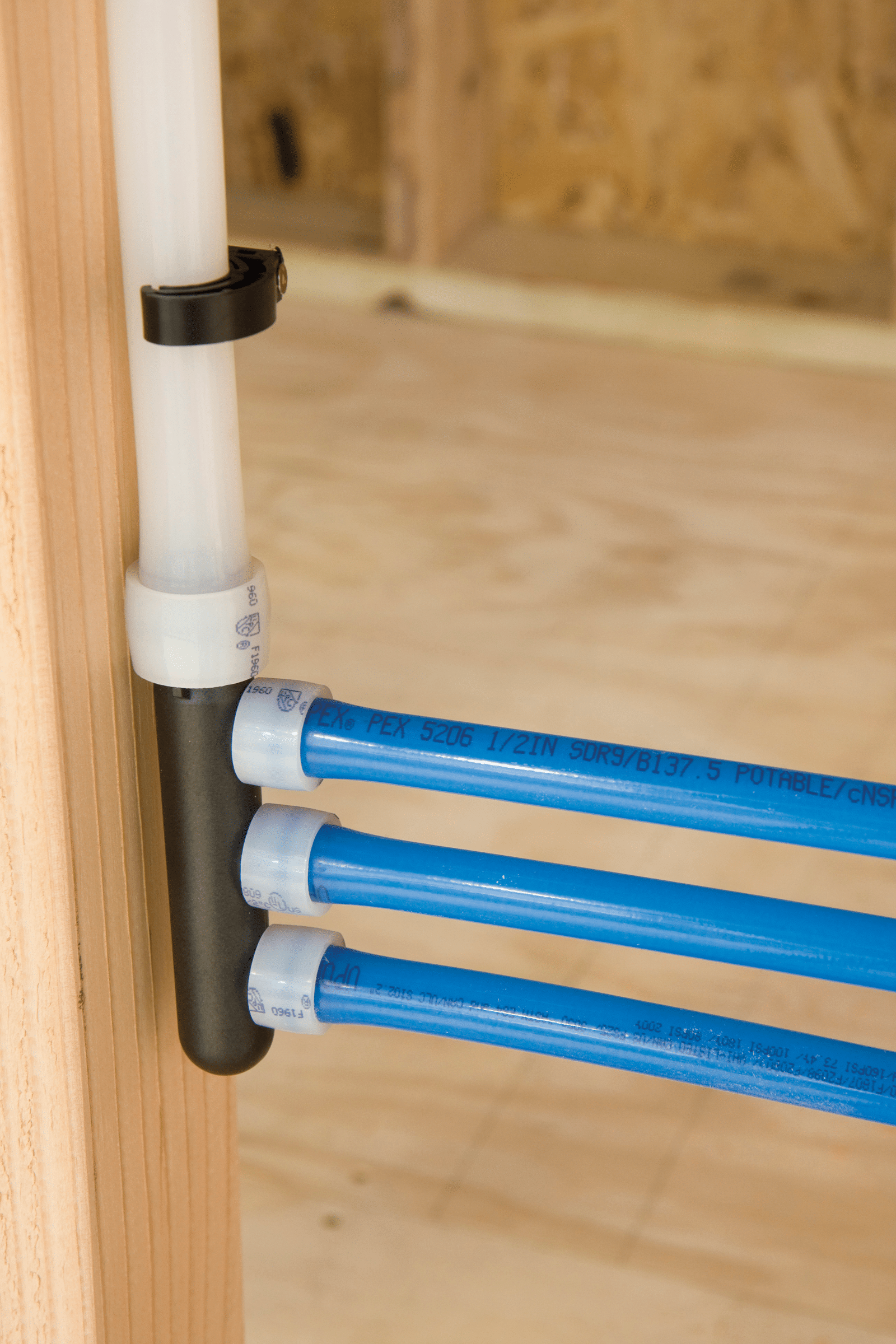

Not only is the manufacturing of PEX pipes more sustainable for our environment, but the systems that make up a building are also more sustainable with PEX. Take for example a domestic water or hydronic distribution system using PEX. Because of its flexibility, PEX can bend around corners with each change of direction instead of having to add a connection. This reduces materials inside a building while also improving water flow and reducing pressure loss for better system efficiencies and performance. Additionally, the smooth interior surface of PEX also means less friction loss in a system as well.

The thicker wall of PEX pipe and its lower thermal conductivity mean it can help keep hot water hotter longer and be more resistant to condensation on cold water lines. In addition, the slightly smaller internal diameter of PEX compared to copper means there is less water is in the system to waste when waiting for hot water.

Because of its flexibility, PEX can bend around corners with each change of direction instead of having to add a connection. This reduces materials inside a building, while also improving water flow and reducing pressure loss for better system efficiencies and performance. Photo courtesy of Uponor

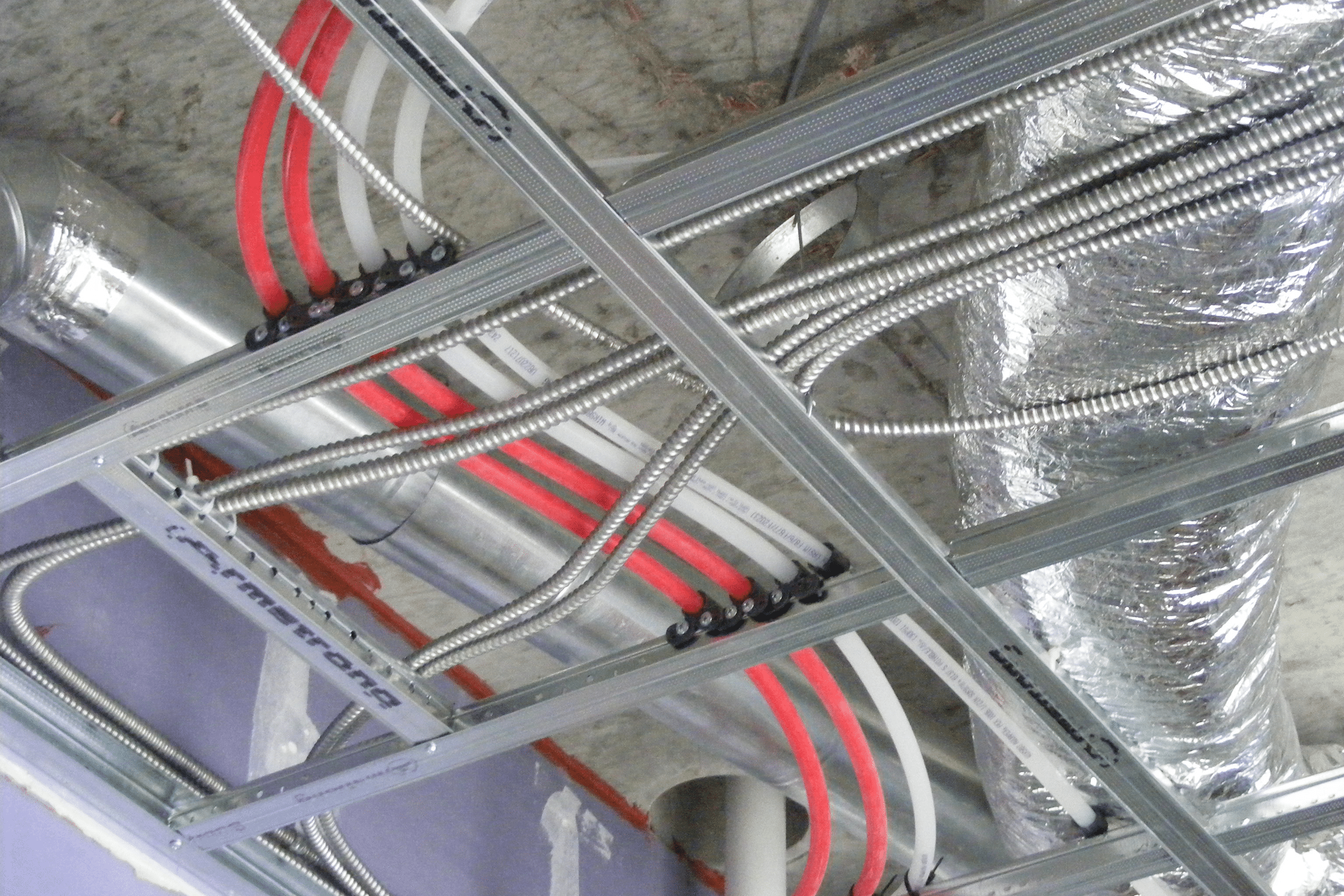

PEX Pipes and Radiant Heating and Cooling: A Sustainable Dream Team

Hydronic radiant heating and cooling systems that use PEX in a slab, under floors, or in the walls or ceilings to transport warm or cool water are also highly sustainable systems. Radiant heating and cooling systems, used in conjunction with dedicated outdoor air systems, can increase indoor environmental quality while reducing overall energy usage. Plus radiant systems work very well with the range of temperatures available through renewable energy sources, such as geothermal and solar, making them even more sustainable.

Over the past couple of decades, the number of radiant heating and cooling systems designed, installed, and commissioned in North America has increased dramatically because of the well-known sustainability factors of the application. Radiant heating and cooling systems provide superior thermal comfort for occupants while offering vastly improved energy efficiency. Radiant heating and cooling systems can also provide greater architectural freedom and more effective control of ventilation.

Radiant heating and cooling systems can reduce overall building energy usage in a number of different ways. Because the heat-transfer capacity of water is much higher than that of air—3,500 times greater—a radiant system that uses a circulator to move water (in lieu of a fan to move air) can achieve the same heat transfer using significantly less energy.

Secondly, because of the way the human body exchanges heat with its surrounding environment, a radiant heating and cooling system can achieve comparable levels of comfort at lower temperatures for heating and higher temperatures for cooling.

With radiant cooling, using higher water temperatures to cool a space may allow for optimum operation of a system’s chilled water plant. Using other sources for chilled water, such as geothermal systems, will make the system even more sustainable. Studies have shown total energy savings for typical office buildings on the order of 17% to 53%.

A notable example of the use of radiant cooling to reduce overall energy usage dramatically is the Pier 15 Exploratorium in San Francisco. The 330,000-square-foot project renovated an existing, unused pier building to serve as the new home for the Exploratorium, an interactive children’s science museum. The project used radiant cooling throughout a majority of the exhibit spaces and the multipurpose event space.

Because radiant cooling systems only require moderate temperatures, the design engineers were able to utilize the San Francisco Bay as a heat sink and source for chilled water. The system uses the bay water, piped through heat exchangers, to provide cooling water for a significant part of the year.

Not only does this innovative use of bay water reduce the overall energy consumption, but it also significantly reduces the building’s water demand by eliminating the need for cooling towers. By using the bay water to serve the radiant cooling system, along with a number of other energy conservation measures, it reduced the building’s electrical energy usage for cooling by a staggering 94%.

Radiant heating and cooling systems are also very low maintenance, adding to the sustainability of the application. The embedded PEX pipe within the concrete slab requires no maintenance, and the heated or chilled water source and distribution requires no greater maintenance than typical fluid-based systems. And, by reducing the size of the airside system, it can also reduce the need for disposable filters and belts.

The Future of Building Engineering

There is no doubt that the commercial building industry is in need of technologies that provide performance, sustainability, cost-effectiveness, and energy efficiencies. So as building owners and the commercial building industry as a whole look for the best ways to meet these challenges, it is our responsibility to ensure that the products and systems we are designing and implementing into buildings are meeting all areas of high-performance building design.

Researching products and systems is paramount to responsible engineering and installation, and we must, as an industry, be committed to finding the best possible solutions for environmental building design to ensure a lifetime of better buildings going forward into our future.