Rigorous product evaluation by an independent third party is key to building safety. Product evaluation reports are a powerful tool that design professionals and building officials can use to improve efficiency of their practice. Here’s what you need to know about what independent evaluation reports means for specifiers, builders, code officials, and the industry at large.

What is a building product evaluation report, and why is it helpful?

The evaluation process exists for a reason: to support the safe installation and use of building products. There is a minimum criteria set forth in the building codes: For those products that meet or exceed these requirements, an evaluation report showing proof of compliance may be issued.

The product evaluation process starts with an independent, rigorous review of industry standards, product test data, and specifications. Qualifying inspections of product manufacturing quality control are also conducted, and an evaluation report is then issued to the building product manufacturer. The evaluation report authorizes the manufacturer to apply the service provider’s mark of conformity to their product as proof of code compliance.

Throughout the life of an evaluation report, quality control inspections are continuously conducted to ensure that no unauthorized changes have occurred in the manufacturing process and that the product has not varied from what was originally evaluated.

International Code Council Evaluation Service (ICC-ES) evaluation reports also help manufacturers bring their innovative technologies to market with independent proof that their products meet the latest building code requirements and standards. Acceptance Criteria (AC) is developed when a code or standard is not recognized for an innovative product. This helps level the playing field for code compliance.

Selection and approval of alternative building products is difficult as is; however, evaluation reports can help streamline critical decision-making.

Does the evaluation involve a site visit to the plants where products are manufactured?

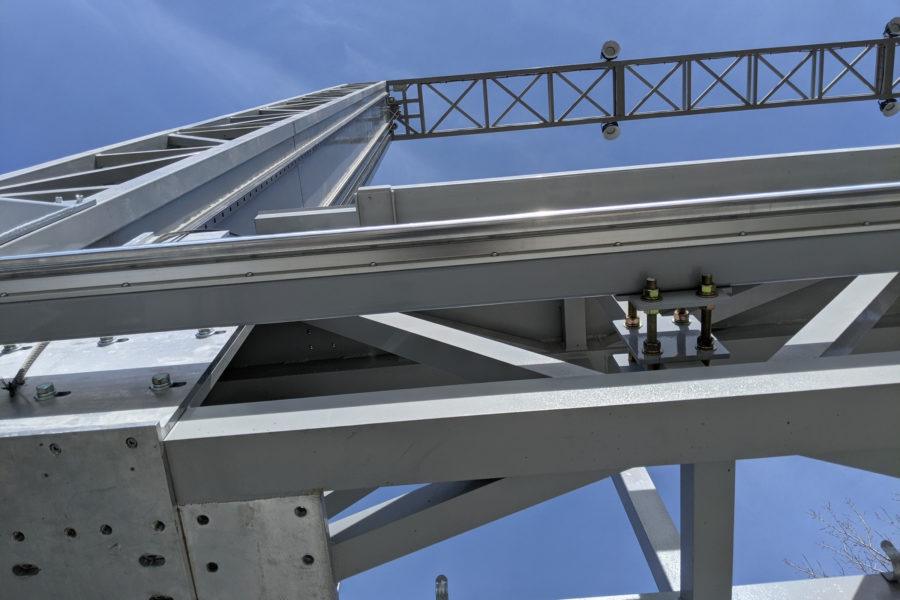

Manufacturing site inspections are part of a successful continuous compliance program. Photo courtesy of ICC-ES, Getty Images

Yes. After the evaluation report is submitted and published, there is a one- or two-year evaluation report renewal. Part of a successful renewal includes a visit to the manufacturing plants to survey the products. This is necessary to make sure that the product continues to comply with the requirements of the standards.

There are two parts to product evaluation. One is testing and the review of the test report, and the other is the evaluation of the manufacturing plant. Those two parts are parallel while the project moves forward, and then they come together towards the end when the inspection is conducted and also when the product evaluation is completed. The inspector consults with the engineer who has reviewed the product and the test reports and submitted the information, and through that consultation and the peer review, an evaluation report is generated.

What’s the biggest advantage that a product with an evaluation report provides?

A growing number of evaluation reports for repurposed shipping containers reflect engagement in a dynamic building material segment. Photo courtesy of ICC-ES, Getty Images

The greatest benefit of an evaluation report from a trusted source is proof of compliance of the product to the set code and normative documents. Specifiers and architects, and code officials and inspectors, can sleep well at night knowing that the products evaluated by ICC-ES have been evaluated rigorously by an experienced engineer or by an organization that has a proven track record to evaluate products to show it has met the applicable codes and standards. What we do, in my view, save lives. Code officials and inspectors approve products for installation after they see one of our evaluation service reports. That tells me that they have confidence in us, they have confidence in our rigorous process, and they have confidence in the experience of our engineers.

For manufacturers, the accomplishment of product assessment adds a level of quality and customer assurance in one’s capabilities and products. For authorities having jurisdiction, evaluations completed by independent technical assessment bodies are the best tool available to clear products for installation/use with ease of mind.

What’s the relationship between the Evaluation Service and the International Code Council?

The ICC-ES is by itself incorporated. It has its own board of managers, and it runs separately from the Code Council. But it is a part of the parent company, which is the International Code Council. Now the definition of independence and third party comes from the ISO/IEC 1700. We have four different accreditations in North America, and all four of them are to the requirements of ISO 17065, which is the international standard for conformity assessment bodies.

We have an impartiality committee composed of manufacturers, government members, and staff. That impartiality committee goes through all the changes to our procedures, some of the evaluation reports that have been published and so on. Then there are internal audits conducted on an annual basis, and on the top of that, we are accredited by four accreditation agencies and they do external audits. All of these activities have a segment within them that goes through the impartiality of what we do and that is just to make sure that we are an independent, third-party organization.

What are some exciting building products that have been evaluated by ICC-ES?

New and innovative approaches to construction include 3D concrete printing, which can be evaluated using ICC-ES AC509. Photo courtesy of Black Buffalo

So many different types of products and assemblies come our way. The ones that have caught my attention fall into the category of off-site construction. These are products that are built up to a point in a factory and then are assembled on-site, and it makes things a little faster and potentially less expensive. There’s a 3D printing robot we’ve seen that actually prints a wall in a matter of one day using concrete, and they can put reinforcements in the middle of it. So that’s very interesting.

The modular building industry has grown dramatically in the US and abroad. Many contractors are now using some form of off-site construction methods, including pods, booths, and private spaces within buildings. ICC-ES AC519 for Enclosed Booths for Installation Inside New and Existing Buildings addresses local variants of the building code. Similarly ICC-ES AC462 for Structural Building Materials from Intermodal Shipping Containers was developed to support this innovative building material segment. Shipping containers are currently being repurposed and converted into a variety of residential, commercial, and industrial facilities including office buildings, storage units, pop-up restaurants, and even temporary hospital or medical facilities.

Are there geographic areas or product categories where testing is more important than others?

I believe every category of product we review that’s part of the construction of a building is important. But having said that, there are certain products that need to go through seismic evaluation, for instance, so that obviously requires some rigorous evaluation. There’s fire safety evaluation to certain ASTM standards like E-84 or E-119. Those are important. Wind load is important. The Florida Building Code has something called high-velocity hurricane zone, and there’s a specific test for that, and that’s specific to that particular region of the country. So those are very important areas of evaluation. Roofing, doors and windows should be evaluated in accordance with the high-velocity zone requirements.

Conformity assessment is critical to safety for residents around the world. Consumers have long been demanding safer building products globally. They require characteristics such as quality, safety, economy, reliability, compatibility, efficiency, and effectiveness to be examined through conformity assessment

Why should all building products be evaluated for code compliance?

Product evaluation for construction matters because at the end of the day, human lives are at stake. I say this and I mean it. It may sound as though I’m making it up, but what we do here at ICC-ES saves lives, and I’m passionate about it. Every time I look at an evaluation report, and I see how rigorous the evaluation has been, I realize that this evaluation can save somebody’s life because the structure is not going to collapse. So that’s very important to me. That’s really what motivates me every day.