Story at a glance:

- The circular economy model aims to eliminate waste and resource over-extraction by keeping materials in circulation for as long as possible via recycling, reusing, refurbishing, leasing, and repairing products.

- Architects, engineers, designers, and product manufacturers can promote the circular economy by reusing materials wherever possible, ethically and sustainably sourcing raw materials, incorporating green energy, and more.

Current data estimates that the built environment is responsible for approximately 40% of the world’s carbon emissions, while the construction and demolition (C&D) industry as a whole produces over 33% of the world’s waste and accounts for nearly half of all resource extraction.

“Excessive waste is the unfortunate byproduct of a consumer culture that grew during a time when the world did not understand the perils of overconsumption,” Richard Skorpenske, head of sustainability and public affairs at Covestro, previously wrote for gb&dPRO. “Through a combination of market forces, design trends, and consumer demand, an ‘extract, use, discard’ cycle became the dominant mode of manufacturing and consumption.”

Historically our economic method of production and consumption has been incredibly linear, following the “take, make, waste” philosophy—resources are extracted and products are manufactured before being sold, used or consumed, and finally disposed of once they are perceived to have outlived their usefulness. This model uplifts convenience and profit at the expense of conservation and sustainability.

This does not have to be the case, as there are other economic models which seek to eliminate waste production altogether and facilitate a regenerative approach to resource use: enter the circular economy.

What is the Circular Economy?

Amsterdam is on track to becoming one of the world’s first cities to adopt the circular economy model. Photo by Alan Jensen

While the concept itself is a bit more complex than can be conveyed in a single article, the fundamental idea behind the circular economy is that of creating a system of production and consumption which emphasizes reusing, refurbishing, repairing, leasing, and recycling existing materials and products for as long as is feasible.

Ultimately the circular economy’s goal is to reduce pollution and waste production as much as possible by extending the life cycle of each and every product or material in circulation. In this way the environment as a whole is less impacted by human activity and is actively encouraged to regenerate what has been lost to over-extraction.

Achieving a circular economy varies depending on the sector, industry, or other socio-economic entity in question; the individual consumer, for instance, plays a different role in reducing waste production than, say, a grocery store or energy provider, though there is some overlap.

12 Ways to Promote a Circular Economy

Here are a few ways in which architects, engineers, and designers can promote the circular economy in their work and projects.

1. Support Circular Economy Education Programs

Skanska USA launched a new, free Supply Chain Sustainability School as a founding partner in January 2025. Photo courtesy of Skanska

As a relatively new concept, the circular economy is not something many industry professionals are familiar with or well-educated on. This lack of knowledge and experience can make individuals and the entities they represent reluctant to adopt new strategies, hindering the advancement of wide-scale circularity initiatives.

Developing, supporting, and engaging with programs that help current and upcoming professionals better understand circular design is crucial to promoting the circular economy as a whole. Covestro—a world-leading manufacturer of sustainable, high-quality polymer materials—recently collaborated with the University of Pittsburgh’s Mascaro Center for Sustainable Innovation and Swanson School of Engineering to develop the Covestro Circular Economy Program, the first graduate program in the United States focused on circular design solutions for global waste. The program is geared towards PhD students and is designed to enable the next generation of leaders by providing opportunities for research and hands-on problem solving regarding waste reclamation and reuse.

Multinational construction and development firm Skanska has also had a hand in educating AEC professionals about sustainable concepts like the circular economy. Skanska and partners launched the Supply Chain Sustainability School to provide free learning opportunities, facilitate knowledge sharing, and promote a collaborative approach to key sustainability issues; the school has trained over 137,000 individuals, hosts more than 500 annual training events, and provides access to more than 200 e-learning modules and an extensive resource library.

In January 2025 the school became available in the US and began seeking partnerships from companies interested in helping shape the school’s development for the US supply chain. “This new resource will provide individuals and businesses with essential resources and educational materials to support their understanding of sustainability strategies that can help scale their business while meeting regulations,” Myrrh Caplan, senior vice president of sustainability for Skanska USA Building, told gb&d. “We are committed to advancing sustainability alongside other school partners, establishing new industry standards and strengthening the skills of our workforce.”

2. Prioritize Renewable Energy

Initiated and developed by the residents themselves, Schoonschip Amsterdam includes 46 self-sustaining floating homes powered by solar energy. Photo by Isabel Nabuurs

Prioritizing the adoption of renewable energy sources over the burning of non-renewable fossil fuels is fundamental to promoting a circular economy. Hundreds of millions of tons of fossil fuel combustion waste—the slag, ash, and other particulates created by the burning of oil, coal, and natural gas—is produced each year, most of which contains toxic heavy metals or other harmful compounds.

These waste byproducts are in addition to the greenhouse gasses (GHGs) produced by fossil fuels as they are burned—the very same GHGs fueling advanced anthropogenic climate change. Incorporating renewable energy sources like wind, solar, geothermal or hydropower helps remove these waste and pollution streams, while also helping to lower a structure’s operating costs. Excess energy can even be shared with others via an energy cooperative or using block chain technology, as practiced by the Schoonschip Amsterdam integrated community in the Netherlands.

It’s important that the transition to renewable energy sources does not inadvertently come at the cost of producing new forms of waste. Lithium, nickel, cobalt, and other high-value materials, for example, are often crucial to the production of renewable energy technology—but the mining of these materials often generates harmful waste that pollutes local soil and waterways.

Fortunately there is already a large amount of these materials in circulation via discarded phones, laptops, and batteries, of which may be collected and repurposed for use in green energy technologies.

3. Use Renewable & Sustainable Materials

Photo courtesy of StructureCraft

Similarly the widespread use of renewable, sustainable building materials—like timber, stone, bamboo, cork, and the like—helps eliminate construction waste in that they may easily be recycled, reused, or left to decompose once they have reached the end of their operational lifespan.

For help in finding sustainable products and considering the environmental impact of building materials, architects and engineers can look to Cradle to Cradle, a platform that certifies products based on their ability to contribute to the circular economy. This makes it easier to design buildings whose materials may be collected and repurposed at the point of demolition, similar to how one draws money from a bank to spend it elsewhere.

“In the future, we will create buildings that are essentially material banks whereby the materials a building contains are selected based upon principles of circular design, material health, and design for disassembly and recovery,” Stacy Glass, vice president at the Cradle to Cradle Products Innovation Institute, previously wrote for gb&d. “In turn, this approach will help owners realize greater economic value, occupants will have improved health, and the environment will bear less of the burden of growth and consumption.”

4. Harvest Natural Materials Sustainably

The Green School in Bali is built almost entirely out of ethically-sourced bamboo, a highly-regenerative plant that may be harvested multiple time throughout its life. Photo by Tommaso Riva

Whether you’re sourcing raw materials directly or purchasing them through a manufacturer, care should be taken to ensure those raw materials were harvested in a sustainable, regenerative manner—or that they are replenished at a faster rate than they are extracted.

Construction-grade timber and wood products, for example, should only ever be sourced from manufacturers or material providers that utilize timber from FSC or Sustainable Forestry Initiative (SFI) certified forests. These forests are managed to strict social, economic, and environmental standards to ensure that biodiversity is preserved and that local peoples’ benefit from the activity.

5. Prioritize Material Reuse

Used tires travel along the conveyor belt at the beginning of their transformation into sustainable, high-performance flooring materials for Ecore. Photo courtesy of Ecore

That said, the reuse of existing materials—even non-sustainable materials like concrete and plastic—should be made priority whenever possible, as reusing these assets ultimately eliminates more waste and reduces the overall demand for new materials. Rubber, for example, has an extremely high potential for reuse, with many rubber goods manufacturers—like Ecore—incorporating recycled rubber in their products. A leading manufacturer of recycled rubber flooring, Ecore diverts approximately 430 million pounds of commercial tires from landfills each year and boasts over 1,500 product variations made from reclaimed rubber.

Once Ecore products reach the end of their operational lifespan, the company’s TRUcircularity take-back program allows Ecore to reclaim and repurpose those materials over and over again. “What Ecore is trying to do, being 100% circular on rubber, is not something any other company has done before. It’s exciting to be at the forefront of rubber circularity and paving the way for more companies to think about what circularity looks like,” Shweta Srikanth, chief circularity office at Ecore, previously told gb&d.

Out of all existing materials, plastic is the most widely available and one of the most uniquely suited to reuse in product manufacturing. Aquafil—one of the leading manufacturers of synthetic fibers for the textile industry—for example, has recognized the role of plastics in the circular economy, as evidenced by their ECONYL fiber.

Made from nylon waste sourced from recycled carpets and fishing nets, ECONYL helps breathe new life into a material often discarded with wanton abandon. “We are trying to create a new world for plastics and fibers that can be regenerated to open the doors to solutions,” Giulio Bonazzi, chairman and CEO of Aquafil, told gb&d in a previous interview. “Making raw materials from renewable sources, recycling them at the highest possible level without the necessity of taking new resources from the planet—this is our vision.”

6. Avoid Toxic Chemicals

Valspar’s Signature paint is one of this brand’s low/no VOC offerings. Photo courtesy of Valspar

While a circular economy primarily seeks to eliminate waste, there is also a focus on reducing pollution and the use of harmful chemicals and compounds in materials and products; we want these resources to be kept in circulation for as long as possible without compromising human and environmental health in the process.

When it comes to the built environment these toxic compounds are most present as volatile organic compounds (VOCs), or gasses that are gradually emitted throughout a product’s life cycle. Long-term exposure to VOCs can exacerbate existing respiratory diseases, lead to the development of respiratory diseases, and even cause certain cancers. Paint thinners, sealants, coatings, adhesives, and solvents are the most notorious VOC producers.

When choosing materials or products for a project, verify whether they bear an LBC Red List Free label. Compiled by the International Living Future Initiative, the Red List is a comprehensive guide to the “worst in class” chemicals, materials, and elements that are known to cause serious harm to human and ecosystem health. Red List Free products fully disclose 100% of their ingredients at or above 100 ppm in the final product and do not contain any chemicals on the Red List.

Most Red List Free products and materials are, by definition, also low- or zero-VOC as well.

7. Implement Regenerative Design Principles

Construction for the MAC Lodge minimized the impact on the neighboring trees. Photo by Chad Holder

From an ecological perspective “regenerative” refers to the ability of an ecosystem—or the land itself and all of its living and non-living inhabitants—to recover and replenish from ecological harm.

Regenerative design in architecture describes a specific methodology or philosophy that views the built environment as an extension of the natural environment and seeks to construct buildings with a positive impact on their respective ecological communities. Rather than simply reduce their consumption of energy or resources, regenerative buildings actively give back more than they take by mimicking the circular biological systems found in nature.

In practice regenerative architecture makes use of a variety of design principles, including: landscape integration, whole systems thinking, resource replenishment, collaboration, and more.

8. Provide Access Over Ownership

The residents of Schoonship Amsterdam use Hely, a sharing mobility platform with a product-as-a-service model that allows members to share cars and bikes between one another. Photo by Isabel Nabuurs

A successful circular economy asks us to interrogate the idea of ownership and consider shared access as a viable alternative. This notion is born out of the realization that, more often than not, customers only require temporary access to a product, after which point the product may be passed on to a new user or returned to the service provider for redistribution.

This strategy has become extremely popular in recent years, with many companies building their entire business model on subscriptions, rentals, leases, or direct sharing instead of selling a product to their customers forever.

The residents of Schoonschip Amsterdam, for example, have reduced their individual reliance on personal vehicles by partnering with Hely, a sharing mobility platform that allows members to share cars, electric bicycles, and cargo bikes between one another.

9. Involve the Community & Design for Multi-Use

Wheeler Kearns Architects designed The Night Ministry in Chicago, renovating three floors of a former manufacturing facility in the Bucktown neighborhood. Photo by Kendall McCaugherty, Hall + Merrick Photographers

Another way to promote equitable adoption of the circular economy is by involving the community early on in the design process for all planned development projects. In conversing with long-term residents, architects and their clients can better understand the needs of the community and the different ways they might use a space over time.

For this reason new building projects should be designed to be flexible (e.g. an open floor-plan that may be easily rearranged) and multipurpose or multifunctional, so that a structure may change and adapt to the community’s needs without necessitating additional resource extraction or the demolition and the construction of an entirely new building.

This concept applies to existing buildings as well—before deciding to build from the ground up, verify whether there isn’t an existing building that has since outlived its original purpose that could be adapted to the community’s or client’s present needs. Similar to reusing materials, reusing an entire structure (or its envelope and framework, at the very least) will always be better than constructing a new one, as it prevents a significant amount of waste from entering landfills and reduces demand for new material.

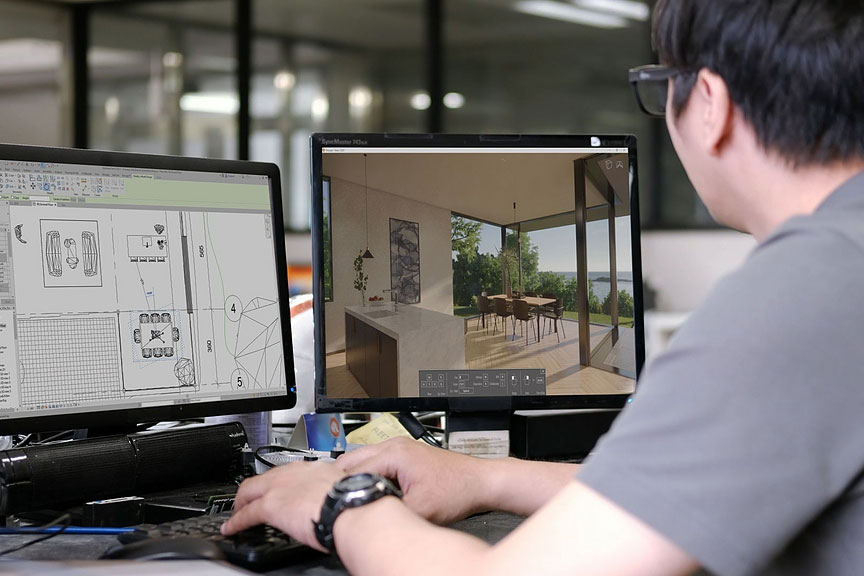

10. Take Full Advantage of Building Construction Technology & Software

3D BIM software can help architects prevent construction-site waste before it happens. Photo courtesy of Enscape

It’s one thing to talk about reducing waste on the job site, but it’s another thing entirely to actually achieve it. Fortunately, advancements in building construction technologies and software—specifically those relating to 3D printing, building information modeling (BIM), real time visualization, building performance simulations, and construction site monitoring—have made it easier for architects to minimize on-site waste production at the outset.

“These technologies deliver a new level of precision to the building process and can significantly reduce waste and rework,” Dustin Stephens, vice president of Sage’s construction and real estate practice, previously wrote for gb&dPRO.

This same line of thinking also applies to preconstruction and prefabrication technology, which offer increased levels of control and quality-assurance that ultimately reduce waste produced by the manufacturer as well as waste produced on the construction site.

11. Conduct a Life Cycle Assessment

DIRTT was the first interior construction provider to complete an LCA for one of their products. Photo courtesy of DIRTT

Another way architects, designers, and even product manufacturers can promote the circular economy is by conducting a Life Cycle Assessment (LCA). This particular tool utilizes scientific principles and methods to evaluate a product or built structure’s environmental impact over the course of its entire life-cycle.

LCAs can help identify potential weaknesses when it comes to a product or building’s waste and carbon production—but they can also help assess potential solutions or other options that may resolve those weak spots. Changing the input parameters of a project’s LCA can also provide insight into how certain factors may influence the performance and impact of the building or product over time.

DIRTT, for example, is a company that provides fully customizable interior environments for a variety of facilities. Part of what makes them special is that they were the first interior construction provider to complete LCAs for their products as a testament to their efforts at attaining circularity. “As a custom manufacturer we recognize that we will always have some waste. However, we work diligently to reduce waste production and responsibly manage what we do generate,” DIRTT previously told gb&dPRO.

When combined with circularity indicators—such as the Circular Transition Indicators developed by the World Business Council for Sustainable Development or the Ellen MacArthur Foundation’s Material Circularity Indicator (MCI)—an LCA can even more effectively measure the circularity of resources and material flows.

Keep in mind that LCAs are most useful and most reliable later in the design process, after there is a better understanding of how certain resources and materials will be implemented within the project.

12. Practice Efficient Communication & Encourage Shared Responsibility

Effective communication on (and off) the construction site can help prevent wasteful errors. Photo courtesy of Sage

Even when practicing the other nine strategies outlined above, construction-site waste can still come about through human error and miscommunication. This can be avoided in part by creating and utilizing effective communication networks that allow all involved parties—architects, developers, contractors, clients, etc.—to stay up-to-date on delays, project setbacks, design changes, and the like.

Cloud-based construction management systems, for example, can drastically improve communication by providing an easily-accessible, collaborative hub where all involved parties can access and relay information in real-time.

Another way to foster effective communication and collaboration is by using the Integrated Project Insurance (IPI) system, a contract between all key parties with conditions that incentivize shared responsibility by eliminating conflicting insurance concerns.

Under an IPI contract, architects can work more closely with material and product suppliers, engineers, and construction professionals to design out waste from the outset or make minor design adjustments as needed to reduce energy, material, time, and money wastage.