Story at a glance:

- REHAU RAU-FIPRO combines PVC and fiberglass to create a higher performing window material.

- RAU-FIPRO can be fusion-welded, forming zero-leakage corners that promise at least 40 years of high performance.

- RAU-FIPRO window profiles are multi-chambered and buildable in larger sizes than standard PVC windows.

In our ever-changing world, where the outside climate has the potential to severely impact indoor comfort, having zero leakage on the windows and doors that make up an increasingly large percentage of the building envelope is crucial to homeowners and commercial building owners alike. To address this demand, REHAU RAU-FIPRO® combines PVC and fiberglass for a best-of-both-worlds, high-performing window material that is currently used in the company’s GENEO® system as well as custom designs from tilt-turns and casements to hungs and sliders.

PVC ranks as the top window and door material worldwide thanks to its energy efficiency, its weatherability, and its ability to be welded and manipulated into arches or curved shapes. But, it is limited in its ability to support sizable windows and doors without the aid of metal reinforcements, which add costs and detract from thermal performance. In this sense, fiberglass has an edge with considerable strength on its own, but it lacks the airtight seal of PVC’s welded corners.

RAU-FIPRO combines these considerable benefits in a co-extrusion process that grants the resulting product the strength of fiberglass with the endurance, weldability, and manipulability of the PVC. Any waste from the co-extrusion process can go directly back to the beginning of the process to be used in future RAU-FIPRO products, while the resulting material has twice the strength of an ordinary PVC material and the thermal performance to earn passive house and zero-energy certifications. Plus, the fusion-welded, zero-leakage corners promise more than 40 years of high performance.

We recently talked to Randy Hoover, engineering manager for the window solutions division at REHAU, about what makes RAU-FIPRO so useful.

What is the RAU-FIPRO material?

Featuring secure, fusion-welded sash and frame corners, these dramatic window and door units invite the light and beauty of the outdoors in while protecting occupants from drafts, leaks, and noise. Photo courtesy of REHAU

When this material was born, PVC was already the global leader in window and door materials. There was a real push to come up with the material of the future. We set out to develop a much stronger material that could be extruded and processed as easily as our high-quality PVC. The added strengthener ended up being tiny strands of glass less than 2 mm long. After much testing, we had the data to confidently introduce RAU-FIPRO as the window material of the future in 2008.

RAU-FIPRO profiles consist of two proprietary materials—a calcium-zinc fortified PVC outer layer and a glass-fiber reinforced PVC inner core. This material configuration has benefits beyond allowing the fabricator to maintain his standard way of producing windows. It reduces dependence on having to place steel reinforcement inside profiles to build the larger window and door units that are in nearly every spec now. Compared with regular PVC, RAU-FIPRO profiles can make units that are as much as 30% larger without metal reinforcing.

How does RAU-FIPRO make use of the strengths and weaknesses of fiberglass and PVC?

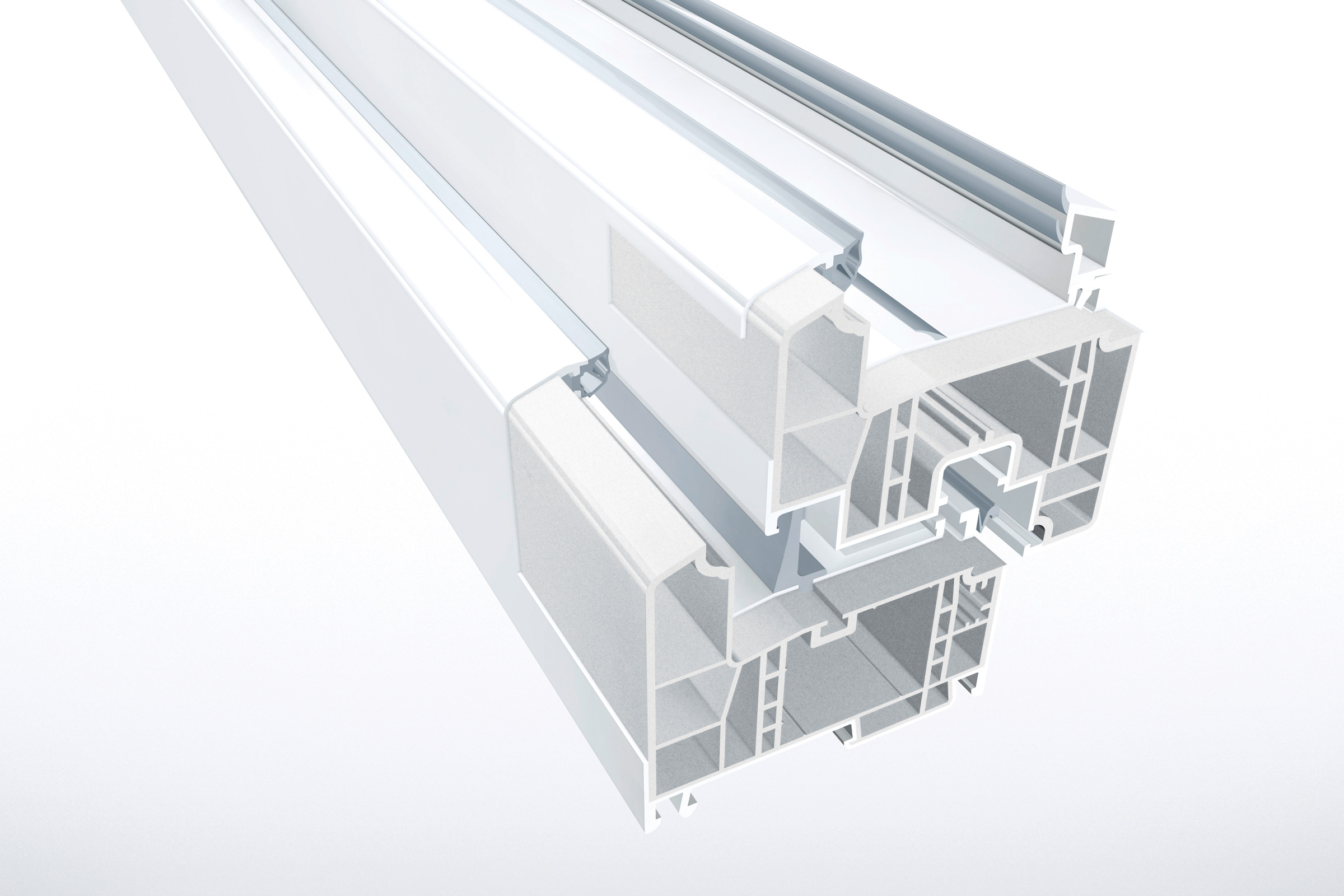

To maximize the integrated reinforcing benefits of their glass-fiber core, RAU-FIPRO profiles have internal ladder-like parallel walls with rungs that increase the strength of the overall unit and act as screw bosses for extra-strong fastening of hardware. Photo courtesy of REHAU

We combined the best properties of both materials into one, resulting in a hybrid material that has the natural insulating and weathering capabilities of PVC with the built-in strength of fiberglass for building larger units.

Like other thermally efficient profiles, RAU-FIPRO profiles have multiple interior chambers that stabilize the profiles and add reinforcement to hardware attachments that get a lot of wear and tear over the years. The material itself has a lot going for it; but the magic happens in how we engineer the profiles. The resulting window or door is much more high performance.

How does REHAU RAU-FIPRO and its compatible system, GENEO, offer high thermal performance?

The glass fibers within the core of a RAU-FIPRO profile act as an internal reinforcement. We call this “integrated reinforcement.” The addition of glass to the formulation provides the reinforcement that normally requires steel inserts, which detract from thermal performance.

In addition, the GENEO profiles have multiple internal walls. Any time you add hollow chambers into an extruded profile, you’re adding thermal benefits. Once these chambers are sealed up and the window is welded together, it’s dead airspace. So it’s a really high-performing thermal barrier—more than 10% better than PVC windows.

What was the overall goal with RAU-FIPRO?

The main goal was to anticipate future requirements and keep our customers happy by not rewriting the script or completely changing the game.

One of our key phrases when we engineer stuff is “sometimes it’s OK to disrupt.” In this case, we didn’t disrupt our loyal customers; we are disrupting the thinking behind what we’ve come to expect of a window. The existing window materials all have their strengths and limitations.

For the future, sustainability is a must have. Each year we’re seeing more demand for passive house and net zero. Some people are motivated by environmental concerns, others by the bottom line, such as developers owning and operating new affordable housing. Regardless, most new buildings also demand larger and stronger windows and doors. RAU-FIPRO allows us to build larger units with ultra high-performance.

Does RAU-FIPRO differ visually from normal PVC systems?

RAU-FIPRO profiles consist of two proprietary materials—a calcium-zinc fortified PVC outer layer and a glass-fiber reinforced PVC inner core—that together provide superior thermal performance, weatherability, and strength to scale to larger unit sizes. Photo courtesy of REHAU

Customers can’t tell the difference. When you compare it to a window made with RAU-PVC, it looks the same. It’s still white or clay in color on all visible surfaces. It can still be produced in other colors. And, it can still be painted or laminated with decorative foils to look like wood and aluminum. There’s just a small tactile difference; we’ve left off the PVC cap in areas that aren’t exposed to sunlight and don’t need the extra UV protection.

Where is RAU-FIPRO best suited?

Like REHAU’s standard PVC profiles, RAU-FIPRO profiles are co-extruded in white or clay. They can be produced in other colors and can be painted or laminated with decorative foils to look like wood and aluminum. Photo courtesy of REHAU

It can be used in both residential and commercial. It is especially well suited to cooler climates and any buildings that have very demanding energy efficiency requirements, for example, buildings aiming for passive house and zero energy.

One of our customers in the upper Midwest uses it for a high-end residential offering. Near our headquarters in Virginia, there’s a house overlooking the Potomac River that uses a custom RAU-FIPRO picture window frame. It is extremely contemporary and has a wonderful view, with very large glass areas. The demand on these units is very similar to a commercial building.

RAU-FIPRO is also going into commercial projects. One of our window fabricators has a multi-family, multi-story project underway right now in Winnipeg with GENEO tilt-turn windows and out-swinging balcony doors.

What certifications does RAU-FIPRO help projects meet? How can it impact a project’s sustainability?

REHAU System 4700, also known as GENEO, tilt-turn windows, and exterior hinged doors were used in Orchards at Orenco—a 3-story, 57-unit affordable housing complex. When opened in Oregon in 2015, the housing complex was the largest Passive House-certified multifamily building in the US. Photo Courtesy of REACH/Ankrom Moisan Architects

Using REHAU RAU-FIPRO profiles, our standard GENEO system has a U-value down to 0.13 that can benefit any residential or commercial project. GENEO has also been designated as a Certified Passive House Component. The big hitter in getting GENEO to this level is enhanced glass. Gas filling between the glass layers is usually enough to get you there, but you also have the options of thicker glass, coatings, and triple panes. PHIUS uses the NFRC simulation referred to as Blue Path for window performance data verification.

By 2022 we’ll have two window styles that achieve passive house. We’re currently adding a new RAU-FIPRO sash to our existing ASPEKT casement design. We’ve done thermal simulations and we’re able to get the numbers we need. Once we get the new sash, ASPEKT will be one of only two casement designs using PVC material in the North American market to achieve the passive house designation.

What does REHAU RAU-FIPRO offer in terms of longevity?

With their PVC outer layer and glass-fiber reinforced PVC inner core, RAU-FIPRO profiles at Seattle’s Point Nautica multifamily property not only meet the requirements for structural integrity at large sizes but also withstand the corrosiveness of the salt water from Elliot Bay. Photo courtesy of REHAU

The exposed PVC surface of RAU-FIPRO is very durable—far more durable than the coatings that must be applied to pultruded fiberglass profiles, for example. Those coatings, much like a fiberglass boat hull or a fiberglass car body, can be scratched off, revealing the glass underneath. REHAU’s PVC and RAU-FIPRO profiles are formulated to withstand the degradation of weathering. They are chemically inert, so they cannot rot, decay, mildew, or degrade from UV exposure.

The addition of glass fibers to PVC makes RAU-FIPRO profiles more structurally stable. They expand and contract 60% less than PVC alone. Anything that’s mechanically joined in the corners of the sash or the frame, whether it’s screwed or glued together, will eventually fail. A welded corner on a PVC or a RAU-FIPRO product is permanently fused, making the joint even stronger than the profile. Throughout the years, as the building envelope expands and contracts, the stability of the profile combined with the stability of the corner joints provide a long-lasting barrier against infiltration from air, water, and sound.

With expansion and contraction over many years, will the two layers of the profile pull apart or become misaligned?

No, they will not. The RAU-FIPRO layer and the standard PVC layer are inseparable. They both come out of the same extrusion dye at the same time; you just have two different materials going into the hopper. We use a form of co-extrusion that actually uses two extruders simultaneously to make the profile. It’s basically the same as a full PVC extrusion with the added benefit of the strength. The PVC surface is formulated to withstand the severest climates in North America, so it will not melt or degrade to expose the RAU-FIPRO core. Unlike the surface coating of fiberglass that can be scratched or peeled off, the UV-resistant PVC surface of RAU-FIPRO is permanent.

What other misconceptions exist around the combination of fiberglass and PVC?

“Do I have to wear a hazmat suit when I’m constructing a product made of REHAU RAU-FIPRO?” The answer is no. There’s very little in the way of any harmful material that comes off the profile. With fiberglass pultrusion, for instance, you most likely need to wear at least a mask or respirator and gloves because the profiles tend to have big strands of glass. RAU-FIPRO uses very short strands of glass fiber mixed with PVC, and once it’s cut it’s basically just PVC dust, which can be easily handled by a fabricator’s dust management system.

Another misconception is that if we don’t train our fabricators correctly they might think they never have to put steel reinforcement in a profile. Our technical information clearly states that you’re able to build up to 30% larger without reinforcement. However, there are several factors, such as fixed versus operable and surface color, that determine the need for additional reinforcement. Especially if the window is black or dark brown colored on the outside, which are currently very popular, there is a lower threshold for reinforcement.

Is there anything else that makes REHAU RAU-FIPRO special?

In this commercial building, the suitability of glass-fiber reinforced RAU-FIPRO profiles literally runs circles around all other window materials. There’s no need to accept the limits to your creativity imposed by the rigidity of pultruded fiberglass or aluminum. Photo by Kuse Aichhorn

Recyclability. Even though it has glass fiber material in it, we put 100% of our scrap back into producing profiles with RAU-FIPRO. We can’t use it in our standard PVC profiles because it has the glass fiber, but we can always use it over and over again to produce REHAU RAU-FIPRO profiles.