Terrazzo & Marble Supply Companies brings history to life with thoughtful artistry and durability embedded in every flooring installation.

Terrazzo & Marble Supply Companies transformed the Duke Ellington School of the Arts in DC with poured-in-place epoxy terrazzo. [Photo: Courtesy of Terrazzo & Marble Supply Companies]

Terrazzo flooring—with its mosaic style and small pieces of marble or granite set in beautifully polished concrete or epoxy resin—is known for its design flexibility and remarkable durability, so it’s no wonder the method has been around for centuries.

“There are terrazzo floors that were installed in the early 1900s that are still nice looking jobs,” says James Bateman, terrazzo division manager of Terrazzo & Marble Supply Companies.

With a little bit of maintenance, these sustainable floors can last 40 years or more without losing their brilliance. Brad Meyer, national sales manager at Terrazzo & Marble, calls them “forever floors” because they last the lifetime of a building.

A Colorful History

References to terrazzo date all the way back to ancient times, but the origins of today’s terrazzo are modeled after 20th century Italian work.

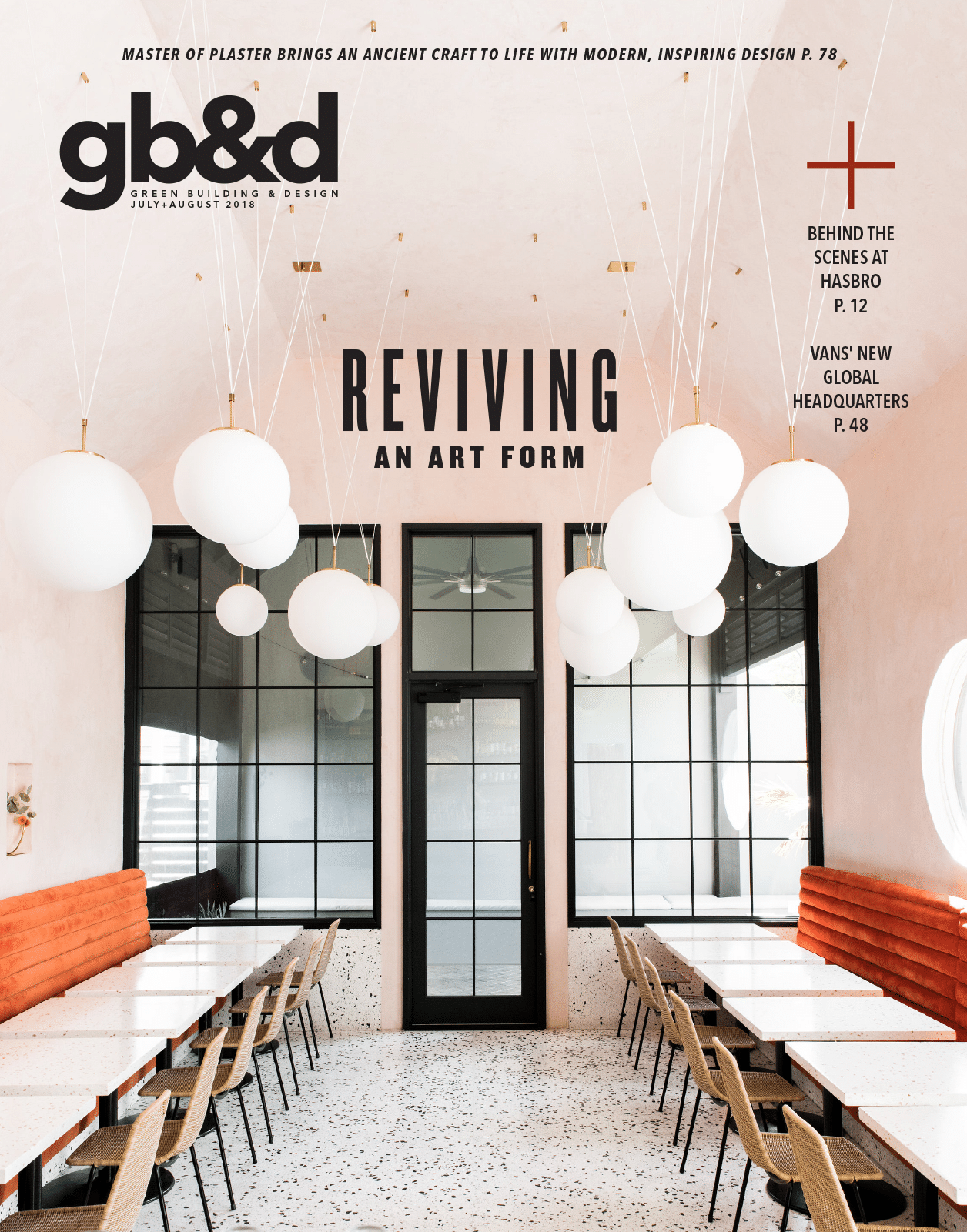

FROM OUR JULY+AUGUST 2018 ISSUE

[Photo: Courtesy of Terrazzo & Marble Supply Companies]

Italian masonry workers used to quarry marble and granite using dynamite. After the explosions, many marble pieces would crumble and fall to the side of the quarry, where workers gathered them and mixed the chips with cement. They poured the mixture on their terrazza (or terrace, in Italian) and ground the material with carborundum blocks to expose the marble inside. “At the time, marble was reserved for the Italian aristocracy—certainly not the laborers at the marble quarries,” Meyer says. But terrazzo gave the working class access to a higher design aesthetic.

As people migrated from Europe to the States, traditional terrazzo workers brought the trade with them, though the industry has certainly evolved over the years. Original terrazzo was set in cement, but now 90% of terrazzo floors are made with an epoxy resin, Bateman says.

A Long Life

While Terrazzo flooring may carry a higher upfront cost, its durability and life expectancy often make it the most affordable option in the long run, Bateman says. When you add up the life cycle costs for carpet, porcelain, or other flooring materials, terrazzo typically ends up saving you money. “It’s definitely the Cadillac of flooring options,” he says. “A lot of people see that initial price tag and they think, ‘Oh, wow. That’s five times the value of carpet.’ But you’re probably going to replace that carpet six times in the life of one terrazzo installation.”

Terrazzo’s durable floors can be seen all over—from Time Inc.’s headquarters to Phoenix Sky Harbor International Airport. [Photo: Courtesy of Terrazzo & Marble Supply Companies]

Terrazzo’s resilient flooring solutions are used in high-traffic areas like schools, stadiums, and airports. Fortunately, they’re also very easy to clean—warm water and a bucket is all you need. And because the terrazzo is poured in place, the flooring is one seamless surface, alleviating hygiene issues. “With Terrazzo, unlike many hard surface materials such as porcelain or ceramic tiles, it doesn’t have grout joints, which is where bacteria and dirt collect,” Meyer says.

Meyer estimates a crew of five men can install 10,000 square feet of Terrazzo in 30 days or less in several easy steps. For floors of multiple colors, each adjoining color is poured one at a time and must cure (or dry) prior to installing the adjacent color, meaning timing can depend on the design’s complexity.

A Sustainable Design

Terrazzo & Marble, which is 100% employee-owned, manufactures its own epoxy that acts as a binder holding the chips together—and it’s the secret to the countless design options available to architects and designers. With the evolution of their epoxy resin technology, the company is able to incorporate materials like aluminum, zinc, and brass as well as exotic aggregates like mother-of-pearl, which consists of crushed seashells. “There’s a lot of color and design flexibility because Terrazzo is poured in place. It’s limited only by the imagination,” Meyer says.

[Photo: Courtesy of Terrazzo & Marble Supply Companies]

Aggregate options also include recycled products like glass, porcelain, marble, and even beer bottles. “We take a lot of things that would be put into the waste stream that we can reclaim and reuse in a terrazzo floor,” Bateman says. Most of their epoxy products also emit zero VOCs, so you don’t have to worry about indoor air quality.

Just as the 20th century Italian workers recycled materials from quarries, some floorings are still made from material scraps. Terrazzo & Marble has a large quarry operation in Texas and often utilizes quarried marble chips for regional projects. This helps minimize the carbon footprint on shipping by using a natural, local product that’s beautiful, too.

Beyond adding whatever you want to the floor, terrazzo is also customizable in terms of color. “You can select any paint manufacturer’s color from their fan deck and we’ll match the epoxy to it. We have people who will send us a piece of fabric and say, ‘Hey, can you match this?’” Bateman says. “We can match virtually any color under the sun.”