Story at a glance:

- PEX pipe is a cross-linked thermoset plastic pipe designed as an alternative to traditional copper, PVC, and PE pipe.

- PEX pipe is extremely flexible, durable, and is considered more sustainable than copper, PVC, CPVC, ABS, and polyethylene pipes.

- PEX pipe can be used for distributing hot and cold water, as municipal water service lines, in hydronic radiant heating systems, and in snow/ice melting systems.

While copper, galvanized steel, and PVC pipe have long dominated the US plumbing market, cross-linked polyethylene (PEX) has grown significantly in popularity over the last decade, with estimates suggesting that PEX piping is used in approximately 60% of all new construction projects.

In this article we’ll cover everything you need to know about PEX pipe, including the different types, benefits and disadvantages, and possible applications.

What is PEX Pipe?

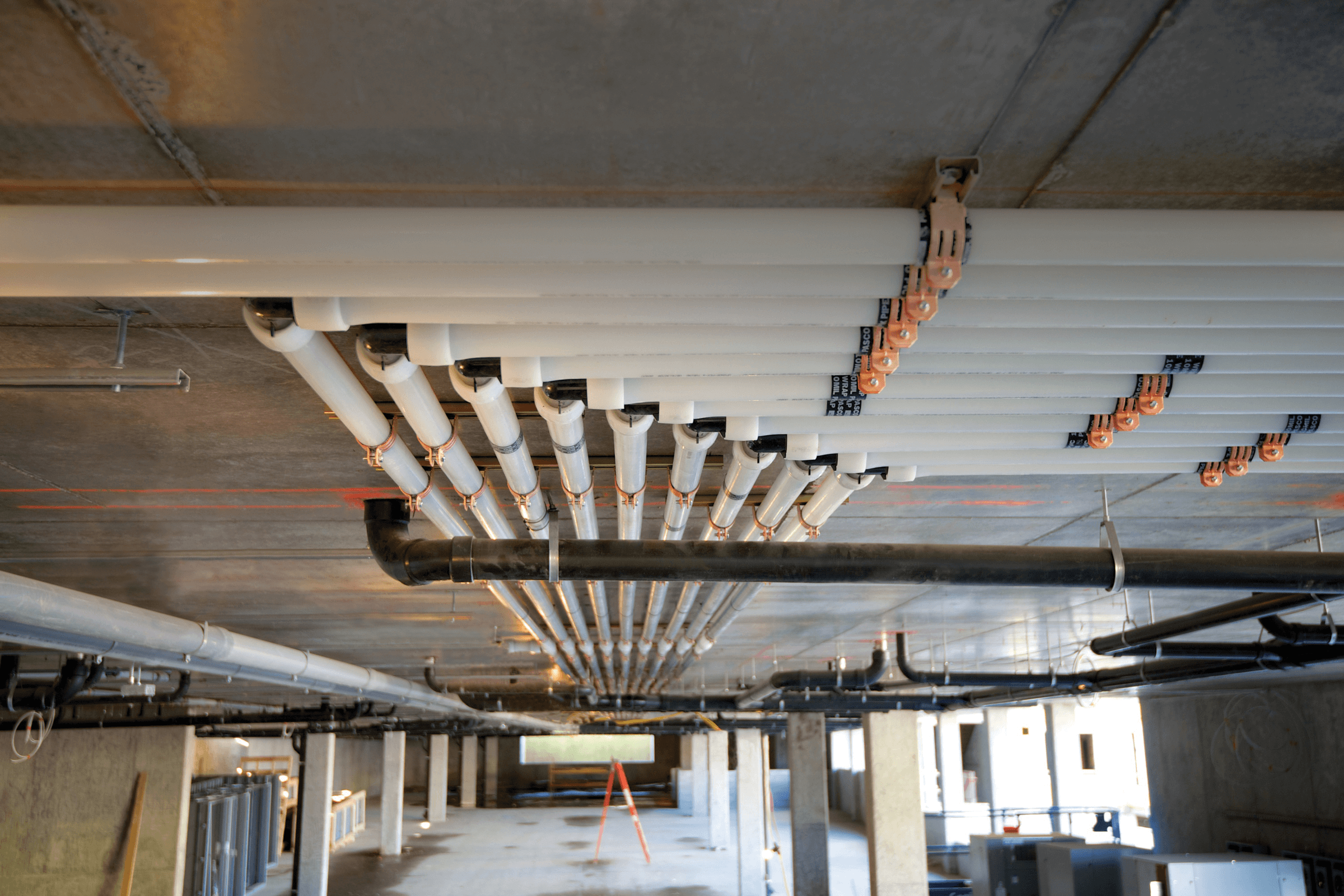

Over the past two decades, PEX has grown to become the most installed plumbing piping product for residential new construction, beating both copper and CPVC combined. Photo courtesy of Uponor

Originally developed in 1968 by German inventor Thomas Engel, cross-linked polyethylene (PEX) pipe is a type of flexible thermoset plastic piping that has started to replace traditional copper, PVC, and CPVC as the dominant piping material for supplying water in residential and commercial construction projects. Almost all PEX used in pipes and tubing is made from high-density polyethylene (HDPE)—a specific type of thermoplastic polymer produced from the monomer ethylene—that is then cross-linked using one of four methods, of which we’ll delve into later.

To be considered true PEX, ASTM Standard F876 requires a degree of cross-linking that is between 65 and 89%. Anything higher greatly increases the likelihood of stress cracking, whereas a lower degree of cross-linking can result in overall poorer physical properties in the tubing.

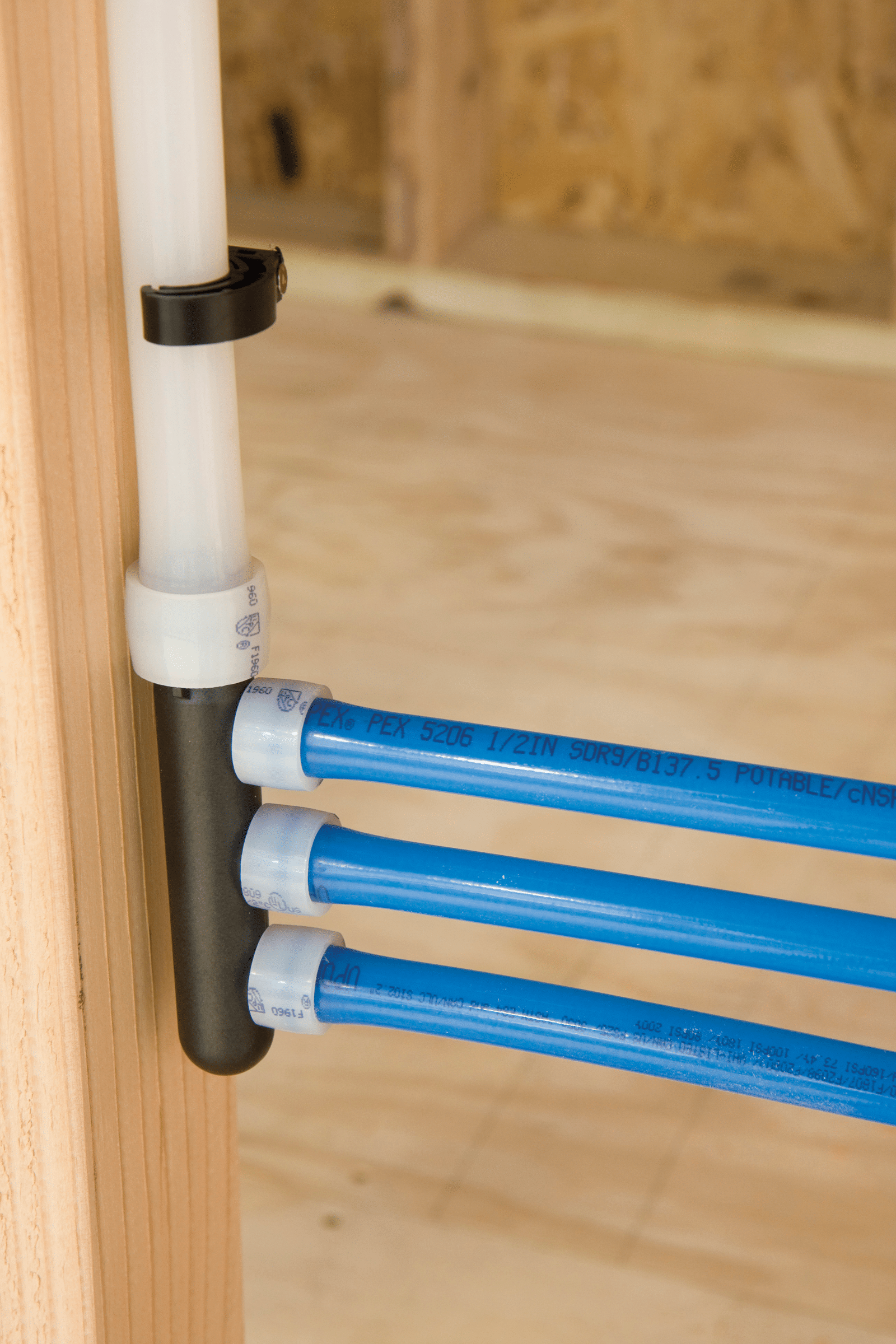

In the US PEX pipe is available in lengths ranging from 10 to 1,000 feet long and can be purchased between three-eighths- to 2-inch in diameter. PEX pipe is color-coded as a means of telling installers which lines are meant to carry hot water and which are meant to carry cold water:

- Red PEX pipes carry hot water

- Blue PEX pipes carry cold water

- White/gray PEX pipes are capable of carrying either hot or cold water

- Orange PEX pipes indicate an oxygen barrier and is only used for hydronic heating

PEX pipe is also available in purple—indicating it is meant to distribute reclaimed water from a water treatment facility—and green, which indicates a wastewater-related application.

Types of PEX Pipe

Different types of PEX pipe are produced via different manufacturing processes, with each possessing slight variations in flexibility, price, and their susceptibility to cracking in freezing temperatures. Photo courtesy of Uponor

There are three distinct types of PEX pipe—labeled as either A, B, or C—with slightly different characteristics as a result of variations in the manufacturing process:

- PEX-A. Manufactured using the high temperature peroxide method and possesses the highest flexibility of all three types, allowing it to expand immensely when exposed to freezing water and reducing the risk of cracking in extreme temperatures; barring its superior flexibility, however, PEX-A has no other major benefits over PEX-B.

- PEX-B. Produced using a moisture-cure technique that makes it less flexible than PEX-A, though it is still capable of expanding to avoid cracking in freezing temperatures; has a high chlorine resistance and is cheaper than PEX-A, making it ideal for residential applications.

- PEX-C. Is manufactured through an irradiation procedure and is the stiffest of the three types, making it more challenging to work with and increasing the likelihood of cracking when exposed to freezing water; PEX-C is, however, the cheapest version of PEX pipe and is ideal for situations that do not require bending around sharp corners.

Technically there is a fourth type of PEX, labeled PEX-D or sometimes PEX-other, that is produced using the so-called Lubonyl process, in which polyethylene is cross-linked via preadded azo compounds after extrusion in a hot salt bath. Currently, however, there are no commercially available PEX-D products that have been approved for potable water use in North America.

Benefits of PEX Pipe

Because of its flexibility, PEX can bend around corners with each change of direction instead of having to add a connection. This reduces materials inside a building, while also improving water flow and reducing pressure loss for better system efficiencies and performance. Photo courtesy of Uponor

There are many benefits associated with PEX pipe, some of which include:

Durable

The cross-linking process makes PEX piping extremely durable and greatly improves its chemical-resistance compared to traditional PE pipes. PEX is also impervious to rust and corrosion, a clear improvement over copper and galvanized steel pipes.

When properly installed and maintained, PEX has an operational lifespan of at least 50 years, greatly reducing the need for costly resource-intensive repairs and replacement work.

Flexible

PEX pipes are also incredibly flexible, a trait that allows them to bend around corners without the aid of connector pieces. “This reduces materials inside a building while also improving water flow and reducing pressure loss for better system efficiency and performance,” Devin Abellon, business development manager for engineering services at Uponor North America—a leading provider of PEX piping products—previously wrote for gb&dPRO.

Long, continuous sections of piping also greatly reduce the risk of leaks—of which typically occur at connection sites—a quality that further serves to improve system efficiency and conserve water.

Sustainable

Despite PEX being plastic, a 2008 life cycle inventory research project conducted by the Plastic Pipe and Fittings Association found that PEX pipes ultimately have a lower lifetime impact than ABS, PVC, CPVC, polyethylene, and copper pipes.

This claim would be further corroborated in 2016 when the Journal of Cleaner Production published a report based on the life cycle assessment comparing the environmental and economic performances of PEX and copper pipes over the life cycle of a student housing project in Lancaster, Pennsylvania. “The results of the analysis indicated using PEX instead of copper piping systems would considerably reduce the total cost of the building up to 63% over its life cycle while reducing the carbon dioxide emissions by approximately 42% and lessening the negative effect of environmental impacts to land, water, and air,” writes Abellon.

Disadvantages of PEX Pipe

PEX pipe has many benefits, but it isn’t without its drawbacks, either. It requires different tools than copper or PVC, cannot withstand long-term UV exposure, and can’t be melted down and recycled into new pipes. Photo courtesy of Uponor

Like any product, however, PEX pipe is not without its disadvantages:

Requires Specialized Tools

While not a major disadvantage, PEX pipe does require specific tools in order for it to be installed correctly. These include:

- PEX cutter. A tool designed specifically to cut through PEX pipe, ensuring clean and smooth edges.

- PEX fittings. Also known as pipe connectors, PEX fittings allow two or more pipes (either of the same or different materials) to be joined or installed where necessary; PEX fittings have barbs that are designed to grip the inside of the pipe and create a tight seal.

- PEX crimp rings. Copper or stainless steel crimp rings designed to join PEX pipes and fittings by applying extreme pressure and creating a watertight seal.

- PEX crimper. A specialized tool used to deform the crimp ring and create a tight seal that prevents leakage.

Attempting to install PEX pipe without the correct tools can result in poorly joined/sealed connections, greatly increasing the risk of leaks. Viega—an international manufacturer of plumbing and HVAC solutions—offers a range of PEX fittings, manifolds, and pipes under the PureFlow family of products. PureFlow is the only PEX system in the industry that offers press transition fittings, allowing for easy transition from PEX to copper tubing in conventional branch and tee installations.

UV Damage

PEX cannot be used outdoors for applications in which the piping remains exposed to the sun’s ultraviolet rays, as it causes the PEX to break down. Now, that’s not to say that PEX pipe is entirely incapable of withstanding some exposure to direct UV light—indeed, most manufacturers promise between one and six months of guaranteed UV resistance. Prolonged exposure to UV light, however, can cause PEX to harden and crack, rendering it useless as a piping material.

This also means it is extremely important that any unused or leftover PEX pipe be stored inside, in an area that does not see regular exposure to sunlight or even artificial fluorescent light, for it to remain viable.

The only way for PEX pipe to be used outdoors is if it is buried underground, in which case it must be approved to AWWA C904 standards. Certain local, city, or state codes may also require that PEX pipe be wrapped in sleeves or some other form of protection if it is to be installed underground.

Minimal Recyclability

Because of its cross-linked molecular structure, PEX pipe cannot be recycled and melted down to create new pipes once it has reached the end of its operational lifespan like copper or PE pipe. PEX pipe can, however, be repurposed for use in other other applications—Uponor, for example, reuses 99% of its scrap PEX as filler for other products or transforms it via clean incineration to extract stored energy that provides heat.

Applications for PEX Pipe

Viega’s PureFlow ManaBloc central manifold for PEX pipes carrying hot and cold water can be seen on the right side of this mechanical room. Photo courtesy of Sweenor Builders

The durability and flexibility of PEX pipe allows it to be used in a variety of potable and non-potable applications, including hot and cold water distribution, municipal water services lines, hydronic radiant heating and cooling, and snow/ice melting systems.

Hot & Cold Water Distribution

Predictably, one of the most common uses for PEX pipe is distributing hot and cold water throughout a building’s plumbing system. Viega’s PureFlow ManaBloc manifold provides centralized control over a building’s entire plumbing network and gives each fixture its own PEX tubing line and accompanying shutoff valve.

Municipal Water Service Lines

Another use for PEX pipe is municipal water service lines. REHAU’s MUNICIPEX family of products, for example, is engineered specifically for municipal applications and includes four core pipes:

- Water service. The MUNICIPEX water service pipe is designed for water service lines applications that run from the main to commercial or residential structures; MUNICIPEX water service is offered in diameters three-fourths of an inch to two inches with coil lengths up to 1,000 feet.

- Pre-insulated water service. MUNICIPEX pre-insulated water service pipe is specifically engineered for water distribution in cold climates that require additional protection against freezing; available in a 2 inch diameter with coil lengths up to 300 feet.

- Reclaim. Color-coded purple and bearing a UV shield, the MUNICIPEX reclaim pipe is intended to transport reclaimed water from the water treatment facility to the point of use; MUNICIPEX reclaim is offered in diameters 1 to 2 inches with coil lengths up to 1,000 feet.

- Force main. Designed for wastewater applications, MUNICIPEX force main pipe is used in residential grinder pump applications to transport wastewater to the main wastewater line; MUNICIPEX force main is color-coded green and is offered in diameters one-and-a-quarter-inch to two inches with coil lengths up to 500 feet.

REHAU is an international provider of polymer-based solutions for construction, automotive, and industry applications.

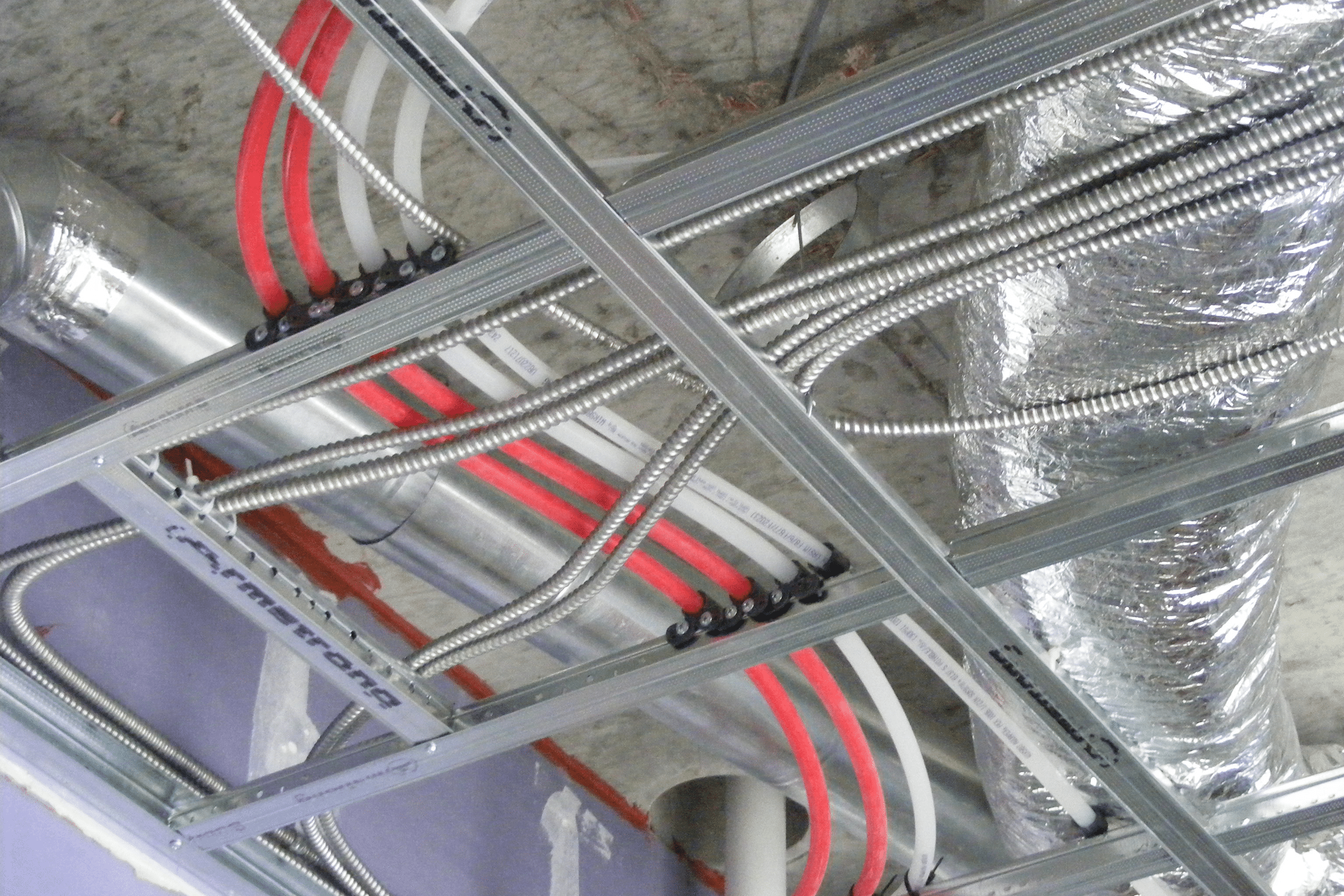

Radiant Heating & Cooling

The Pier 15 Exploratorium project in San Francisco uses PEX embedded in a concrete slab to circulate water from the San Francisco Bay as a heat sink and source for chilled water. Photo courtesy of Uponor

PEX pipe is also well-suited for use in radiant heating and cooling systems. When PEX pipes were first introduced to North America in the 1980s, they were mainly marketed for use in underfloor hydronic radiant heating systems. The contemporary green building movement has led to a resurgence in the demand for hydronic radiant heating—and by extension, PEX pipe—as such systems offer supreme energy efficiency over traditional forced air systems.

“Water has the capacity to transport energy 3,500 times greater than air,” Kim Bliss, content development manager at Uponor, previously wrote for gb&d. “That means a hydronic radiant heating system that uses water to heat a space rather than air will be much more energy-efficient.”

PEX’s incredible flexibility allows it to be laid out in a continuous series of loops and backtracks for radiant heating applications, greatly reducing the risk of connection-site leaks—an important quality seeing as radiant heating systems are intended to be low maintenance. “The embedded PEX pipe within the concrete slab requires no maintenance, and the heated or chilled water source and distribution requires no greater maintenance than typical fluid-based systems,” Abellon wrote. “And, by reducing the size of the airside system, it can also reduce the need for disposable filters and belts.”

Snow & Ice Melting Systems

While technically a form of radiant heating, hydronic snow/ice melt systems are designed to use heated water to melt snow and ice from sidewalks, driveways, and other surfaces. PEX—and particularly PEX-A—pipe is the ideal piping solution for such systems, as its high level of flexibility reduces the risk of cracking in freezing temperatures.