Story at a glance:

- gb&d goes behind the scenes to tour Hydro Aluminum Cassopolis, one of the largest recyclers of aluminum in the US.

- The Michigan facilities have capabilities unlike others in the industry, from automation to testing, with a state-of-the-art laboratory onsite.

- Recycled aluminum from Hydro ends up in everything from high-end electric vehicles to luxury furniture. Hydro CIRCAL is made of a minimum of 75% post-consumer scrap.

In a city of less than 2,000 permanent residents, a global company is turning old car parts and chopped-up electrical wire into components for some of the world’s top electric and luxury vehicle manufacturers, high-end furniture-makers, architects, and more.

US, Norway, and Hydro flags wave in the breeze outside the main Hydro Aluminum Building in Cassopolis, Michigan. Hydro started in Norway 120 years ago and today has 33,000 employees all over the world—with more than 6,000 of them now working at nearly 30 locations across the US.

Hydro has more than 30 locations across North America. Map courtesy of Hydro Aluminum Cassopolis

Hydro Aluminum Cassopolis—reported to be the newest, most modern recycling-based extrusion ingot casthouse in the world—opened in 2023 and is a $150 million recycling investment. The plant is able to produce 265 million pounds of recycled aluminum billets annually and brings commercial-scale production of its Hydro CIRCAL to the US with a dedicated delacquering line. Circular materials like the low-carbon, recycled Hydro CIRCAL alloy are seeing growing demand from leading architects, product designers, and manufacturers.

This is the circular economy.

“This is the circular economy,” says Duncan Pitchford, president of Hydro Aluminum Metals USA and head of Commercial Americas. “We’re taking end-of-life stuff, turning it into new stuff, and doing it without having to run a big, monster aluminum smelter. Recycling aluminum takes 5% of the energy as producing primary aluminum.”

The HYDRO Chair, designed by Tom Dixon using Hydro aluminum, is lightweight, durable, and fully recyclable. Photo courtesy of Tom Dixon Studio

Photo courtesy of Tom Dixon Studio

In early fall 2025 Pitchford walked a team from gb&d through the new facilities for a behind-the-scenes tour—from collecting metal scrap to turning it into liquid metal in a large furnace to casting it into large logs of high-quality aluminum ready to be sold.

Onsite Innovation

At Hydro Aluminum Cassopolis, post-consumer scrap is transformed into one of the lowest-carbon aluminum products on the market, now available for commercial use across architecture, furniture, lighting, and more. Photo by Pete McDaniel

A mountain of metal can be found inside the Hydro Cassopolis plant on any given day. “It’s all largely window and door parts in my hand here,” says Duncan Pitchford, president of Hydro Aluminum Metals USA. “That’s a threshold from the door. You can see it’s got paint on it, and that paint is a challenge for us in the production process because it is a contamination.” Paint creates “dross,” or an aluminum oxide contamination that forms on top of the melt in the furnace. Hydro removes the paint in a delacquering kiln without completely burning it, then using that organic content as a fuel source to help melt the metal. Photo by Pete McDaniel

Plentiful scrap exists in the area around Cassopolis, both from industrial activity and from scrapyards. Hydro brings that material in and inspects it to know what they have in any given load. Scraps are segregated by type using HySort technology—the result of more than a decade of development. Scraps are sorted by alloy before Hydro’s unique software system provides details for what to use based on what materials are available and what the metal is needed for. Photo by Pete McDaniel

Hydro can do things in Cassopolis that others in the industry simply cannot do—or certainly not at the same level, Pitchford says. Delacquering and low-pressure casting distinguish the plant from any other extrusion ingot recycling plant in the US, he says.

Pitchford grabs a handful of metal pieces from a shimmering mountain of the day’s dropoffs. “It’s all largely window and door parts in my hand here,” he says. “That’s a threshold from the door. You can see it’s got paint on it, and that paint is a challenge for us in the production process because it is a contamination.”

Paint creates “dross,” or an aluminum oxide contamination that forms on top of the melt in the furnace. “The more paint and stuff you have, the more dross you get. Dross for us means the process is not efficient and we’re losing aluminum.” The delacquering kiln removes the paint from the metal without completely burning it. Then that organic content is used as a fuel source to help melt the metal.

Some of the technology in Cassopolis, like the delacquering system, differs even from Hydro’s other plants. “We take shredded scrap—parts from cars and old windows, demolition projects and things like that—and feed it through this big rotating drum,” he says. “That burns the organics off, and then we can melt that material in a controlled way. There’s not another facility like this in North America that has this technology. It lets us use a lot more end-of-life post-consumer scrap.”

Hydro CIRCAL is made of a minimum of 75% post-consumer scrap and has been used for automotive components, lighting, and architectural building construction projects, including for windows at an airport terminal building in New York. “It performs just like the other products we make; it’s just we made this with at least 75% post-consumer scrap,” Pitchford says. “It’s just as strong, same mechanical properties, same performance properties.”

Hydro also invented its own proprietary casting technology that lets them do things others can’t, Pitchford says, particularly for the automotive industry, including with what he calls the “more challenging alloys.”

“Hydro is the largest or second largest recycler of aluminum in the US. We have a total of 11 recycling plants—the three that are in our business unit and eight in our extrusion business unit. Next year we’ll produce about 2.3 billion pounds of this stuff. But of course we’re always looking at opportunities to grow, and we think the market will continue to expand,” Pitchford says. “Use of aluminum in the automotive industry continues to increase, and the automakers are increasingly interested in that being recycled aluminum. The big automakers all have climate targets themselves. They’ve made promises to their customers, and we’re here to deliver on those promises.”

Those automakers also build globally, he says, pointing to Mercedes—one of Hydro’s customers. “If you’re Mercedes or BMW or Volvo or Toyota or Honda, you’re building the same vehicle in Europe that you’re building in the US that you’re building in Japan. It’s the same architecture, the same components. If they can they like to buy from the same suppliers. As a global company that’s one of our advantages and one of our challenges, to serve that kind of demand, but when Mercedes makes a decision that they’re going to build this type of vehicle and they’re going to do it using recycled materials, they’re going to do that in Europe, and they’re going do that in Alabama.” He says Hydro is talking to automakers today about cars they will start building in 2029 or 2030. “That’s the planning cycle, and that planning cycle is election agnostic.”

Safe, Streamlined, Sustainable

Photo by Pete McDaniel

Hydro is cleaning up the industry—and the earth—with boundary-pushing aluminum manufacturing and recycling technology, advanced scrap sorting, and low-carbon remelting. Many of its processes are automated. Photo by Pete McDaniel

Inside Hydro Aluminum, facilities are clean. Processes are transparent. Task cards are turned from red to green as daily jobs are completed, while any issues are marked as deviations and clearly shown on screens so anyone can click to open the case, see the status, or help to resolve it.

“We put a lot of focus on these things,” Pitchford says. “You can see the plant is fairly clean, and cleanliness is an indicator of safety. A clean plant is a safe plant. It means people are taking their time; they’re not rushing. Cleanliness is also a leading indicator of quality. If you have a clean plant that means things are under control, you’re being careful, and you’re more likely to have produced a quality product. And we’re always looking for ways to improve and make things better.” When we talk in September 2025, the plant had zero reportable injuries since opening in 2023.

Working in the mold shop is one of the most important roles at Hydro. “If the molds aren’t perfect, you end up with a mess very quickly.” Photo by Pete McDaniel

The company also takes pride in its EPDs and, when delivering CIRCAL, includes a test certificate that shows how much post-consumer scrap was included. Pitchford shares a recent certificate proving the batch used 82% post-consumer scrap.

Hydro is also developing a zero-emission smelting technology called HalZero. “In the smelting process as it exists today, CO2 is emitted based on how it uses a carbon anode. The anode consumed in the smelting process is a chemical reaction, so you emit CO2,” Pitchford says. “The carbon from the anode binds with the oxygen that’s in the alumina and you have the CO2 emission. That’s the way aluminum has been made since the modern aluminum industry emerged. To deal with that you have to change the smelting technology.”

Hydro’s proprietary technology HalZero is based on converting alumina to aluminum chloride prior to electrolysis. Chlorine and carbon are kept in closed loops, resulting in a fully decarbonized process for primary aluminum. Hydro is piloting HalZero to industrial scale before 2030, looking for public funding and partnerships for industrialization.

The company is also working to significantly reduce its total emissions of sulfur dioxide, nitrogen oxide, and dust as part of its 2030 target to reduce material non-GHG emissions by 50%.

Improving Processes

Walking through a lot full of aluminum logs, Pitchford identifies various stacks by their stamped numbers. “This will be made into automotive trim components for a certain well-known German auto manufacturer,” he says of one grouping bound in green straps. Photo by Pete McDaniel

Many of Hydro’s processes in Cassopolis are automated, which helps to further reduce risks on the floor. Three autonomous homogenization ovens and two cooling chambers heat and cool the metal in a highly controlled environment. Before that, though, the charge car dumps scrap in the furnace. In the old days an operator would handle that process manually, Pitchford says. Some still do, but not at Hydro. “Here they load it on this autonomous piece of equipment, and then that slides over to the furnace and puts the scrap in. That way you remove the safety risk to the operator.”

Another autonomous process is ultrasonic testing, completed once the metal logs are cast. This ensures logs have no cracks or large exclusions. “This is fully automated. There are 24 different ultrasonic heads on it,” Pitchford says. Just like an ultrasound at the doctor’s office, it requires liquid. For this ultrasound that liquid is water, which transmits sound waves. “In most plants, including most of ours, you do this manually with a handheld device. You check certain areas on the logs to see if there are any cracks. It works, but like any manual process, it’s susceptible to error.”

Safety is key inside Hydro’s facilities. Processes are transparent. Task cards are turned from red to green as daily jobs are completed, while any issues are marked as deviations and clearly shown on screens so anyone can click to open the case, see the status, or help to resolve it.

Photo by Pete McDaniel

Many of Hydro’s processes in Cassopolis are automated, which helps to further reduce risks on the floor. Three autonomous homogenization ovens and two cooling chambers heat and cool the metal in a highly controlled environment. Photo by Pete McDaniel

The Cassopolis plant is not “most plants.” “This is 20 years of learning put into one new plant. We operate recycling facilities in Europe and the US and Brazil. Of course equipment suppliers are always trying to improve as well. When we’re making these safety-critical automotive components, having the best available technology is what we want to do,” Pitchford says.

An intense level of care and control is illustrated from the very beginning of Hydro Aluminum’s process in Cassopolis. Their proprietary laser induced breakdowns spectroscopy (LIBS) technology allows the company to sort scrap by alloy at scale so they know the exact alloy composition.

This is 20 years of learning put into one new plant.

“People think aluminum is aluminum. It’s not. Think about the aluminum can your Coke is in; the sides of it are kind of soft, and the top is hard. That’s because they’re different alloys. The side of the can is a 3000 series alloy, and the top is a 5000 series alloy. What we’re making here is a 6000 series alloy.”

Different trace elements are added to achieve different properties, too. “If you are looking to have the soft sides of the aluminum can, you would use less of certain trace elements, but for the harder lid of the can, you need some more magnesium. You would do something similar for car parts as well, depending on what you are making.”

Plentiful scrap exists in the area around Cassopolis, both from industrial activity and from scrapyards. Hydro brings that material in and inspects it to know what they have in any given load. Scraps are segregated by type using HySort technology—the result of more than a decade of development.

Scraps are sorted by alloy before Hydro’s unique software system provides details for what to use based on what materials are available and what the metal is needed for—say a car’s bumper beam or a crash can, designed to crush in an accident. “It says, ‘This is the stuff we don’t want, and this is the stuff we want,” Pitchford says. “The beam is very rigid, very strong. The crash cans are softer and designed to absorb energy. We have a lot of R&D that goes into this process to make and test these different alloys.”

The advanced technology is what allows Hydro to use so much end-of-life scrap. “We have this software tool we’ve been running in the company now for over 20 years, and it learns. It’s uniform across our plants so the data sets are interchangeable, and we can use that information to really drive improvement.”

In the Lab

Beatrix Remigio, laboratory engineer, works with Hydro’s state-of-the-art scanning electron microscope. “This kind of capability distinguishes us from most in the industry,” says Duncan Pitchford, president of Hydro Aluminum Metals USA. Photo by Pete McDaniel

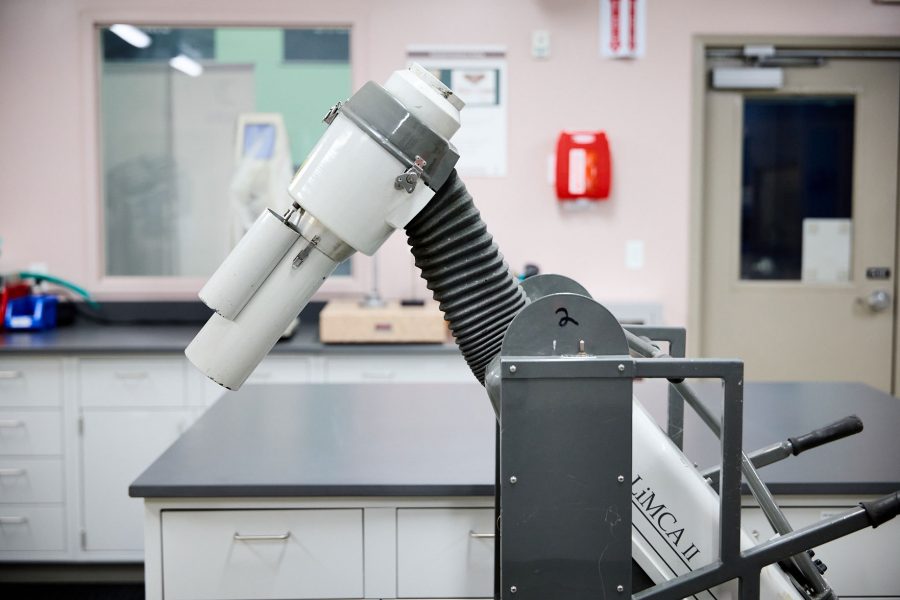

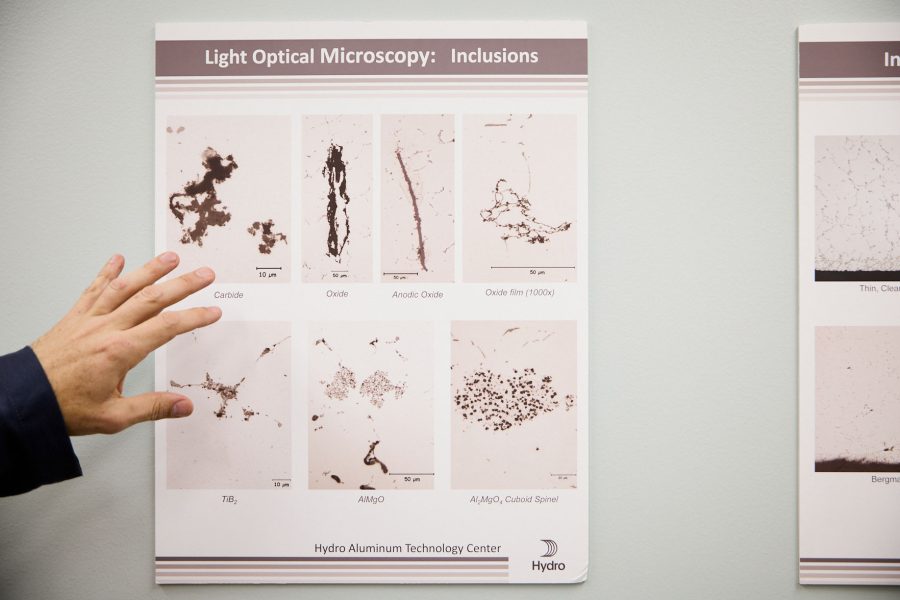

Next door to where the scrap is sorted, melted, and cast, the Hydro Aluminum Technology Center (HATC) is focused on highly technical alloy development and testing as part of Hydro’s leading global R&D network. It’s one of three Hydro technical labs globally—two more are in Norway. Even outside companies rely on the work that is happening inside the HATC.

“What’s unique about this lab is, although it’s our lab, we can test our own material and certify it to the market as if we were a third-party. We have third-party accreditation. If General Motors or Ford wants a testing report, we can give it to them, and they will accept it as if it came from an external consultant,” Pitchford says.

The Hydro Aluminum Technology Center is one of three Hydro technical labs globally—two more are in Norway. Even outside companies rely on the work that is happening inside the HATC. Photo by Pete McDaniel

Photo by Pete McDaniel

The star of the show inside the HATC is the scanning electron microscope, which can achieve a resolution of just over one nanometer. “Ten times more and you can actually see the atom,” says Eystein Vada, research scientist and one of Hydro’s R&D engineers who helps Hydro customers work through issues or develop new products.

The microscope is incredibly sensitive—and expensive—equipment that provides technical competence few can match. “This kind of capability distinguishes us from most in the industry,” Pitchford says. “We use these resources to work directly with our customers. Other companies producing aluminum extrusion ingot, they don’t have this. Or if they have it, it’s less sophisticated and they only use it internally, not for customer support.”

We can test our own material and certify it to the market as if we were a third-party.

A multi-camera system is another new machine inside the lab. It provides an image of a sample being tested as the test occurs. “It’s almost like the backup camera on your car, the way you can see all around the car. Here you can see all around the sample, and it shows you exactly how it breaks,” Pitchford says.

The Hydro Aluminum Technology Center is focused on highly technical alloy development and testing as part of Hydro’s leading global R&D network. Photo by Pete McDaniel

Photo by Pete McDaniel

In another area of the lab, corrosion testing chambers could run for months to make sure a piece of metal will perform as required. “Think about that bumper beam in your car. You don’t want that to corrode prematurely. With these corrosion testing chambers we can essentially accelerate corrosion.”

The lab relocated from Zeeland, Michigan, to be nearer the new factory in June 2024. “It was the perfect business case to be close to production, to showcase our capabilities to customers together with the plant,” says Esma Senel, the global head of laboratories for Hydro. Senel was working at the Cassopolis plant rather than her typical location at the R&D center, lab, and test site in Karmøy, Norway, when we visited in September. “I’m here just for a few days, but this laboratory is quite deep in my heart,” she says, taking pride in her work. “I was here for eight months helping to get it set up.”

Hydro started in Norway 120 years ago and today has 33,000 employees all over the world—with more than 6,000 of them now working at nearly 30 locations across the US. Photo by Pete McDaniel

By the Numbers

1,000

Hydro’s state-of-the-art equipment can sort 1,000 pieces of scrap metal a second.

2,700

2,700 metric tons of shredded scrap a month go into product.

650

650 tons of chopped-up electrical wire a month go into product.

265

The plant is able to produce 265 million pounds of recycled aluminum billets annually.