Story at a glance

- Air loss through duct leakage in buildings is one of the biggest contributors to energy waste in US buildings today.

- Research from ASHRAE indicates that 75% of ducts leak 10 to 25%.

- Aeroseal audits buildings and solves leaks fast, improving IAQ and temperature control.

Indoor air quality is more important than ever. What started in 1993—when engineer and HVAC expert Mark Modera invented a breakthrough aerosol-based sealing technology in a garage—is now widely recognized as a critical step in building design.

Hospitals, offices, K-12, universities, you name it—project teams all over the world are turning to Aeroseal for help, as up to 75% of buildings have leaky ductwork, according to ASHRAE.

April Frakes, director of commercial business development at Aeroseal, works with customers to make existing commercial buildings better and eliminate that costly leakage. She’s been with the company for eight years and seen it grow from 38 to 200-plus employees. She says it’s different from any role she’s been in before because it centers on helping people understand what’s happening. “A lot of times people know they have a problem, and they go to find a solution. With Aeroseal technology, it’s a lot of education. People know the building is problematic, but they don’t know exactly what’s causing it,” she says.

Because ductwork is hidden behind walls or above ceilings, people often don’t think about it once it’s installed—out of sight, out of mind. “A lot of what our company does is educate people about the importance of having tight ductwork and why it’s important that your exhaust system works as designed,” Frakes said.

We recently talked with Frakes more to find out how Aeroseal can help buildings improve their indoor air quality, temperature, comfort, and more.

When does Aeroseal get involved with a building?

A lot of times we’re called in because there’s a problem—especially for indoor air quality issues.

We worked on an office building that had a morgue on the first floor in the basement. The smells were making it all the way through the building. They put in a new exhaust fan and did all the things they thought they could to solve that problem. People were moving out of that building all the time; they weren’t able to keep tenants. Finally somebody said, “What about Aeroseal?” We were able to come in and seal up that exhaust duct.

If your exhaust ductwork is leaking, all of those smells you are trying to exhaust out are actually leaking through to other floors. We were able to seal that exhaust ductwork and solve their problem.

We also worked with a children’s hospital in Florida. They were having trouble with contaminants, with viruses making it throughout the hospital, and they weren’t sure how this was happening. This was even before Covid. There was a leaky exhaust; the things that were supposed to be taking contaminated air out of the hospital were not working properly. By sealing up that ductwork we were able to solve a lot of those problems.

Those are extreme cases, but even if you’re in an office building with multiple floors and somebody’s cooking on one floor, that can be a problem.

How does Aeroseal help with other issues—like temperature control?

We work with a lot of schools, and we see a lot of space heaters. Or in hotter months you see teachers trying to speak over a fan. We see kids wearing coats in classrooms in winter. It’s all because the air is not making it to where it’s supposed to go. That’s all due to duct leakage.

How common is duct leakage?

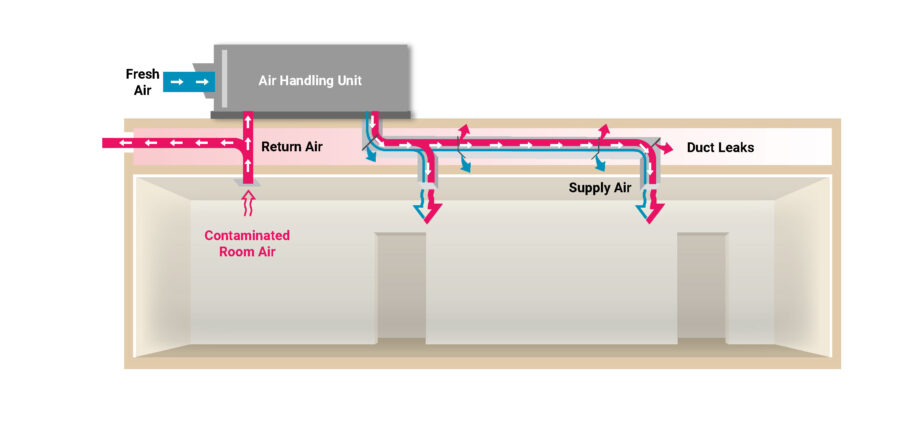

HVAC system with unsealed ductwork. Illustration courtesy of Aeroseal

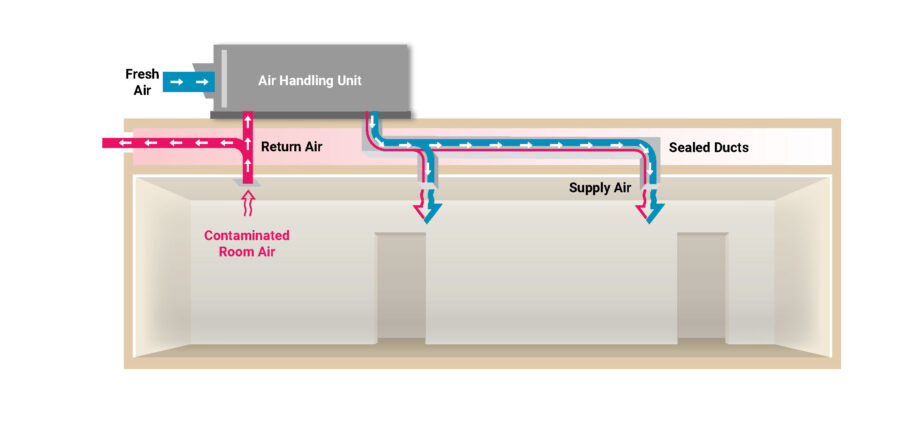

HVAC system with sealed ductwork. Illustration courtesy of Aeroseal

ASHRAE tells us that up to 75% of ducts leak 10 to 25%. We find that to be true in the tens of thousands of commercial buildings we have dealt with throughout Aeroseal’s history. Those are common numbers.

You can imagine, especially with Covid and people trying to make sure they’re bringing the right amount of fresh air into a space, if you’re leaking out 20% and you’re only bringing in 20% of fresh air, a significant amount is not making it into that space to dilute all those contaminants. There’s a huge problem people don’t even realize is happening because it’s hidden above the ceiling or behind the wall.

How does the sealing process work?

When Aeroseal comes in, whether we’re doing an exhaust system or supply ductwork, I compare it to painting a room. You have to prepare your room for that paint. You spend time putting that blue tape over all of the trim and doors—anywhere you don’t want to get paint on. It’s the same with Aeroseal. The majority of our process is preparing the system so we don’t get sealant where we don’t want it to go. We pressurize that duct system so the sealant comes in and fills up all those holes and gaps.

Most of our labor is really blocking off those exhaust grills or, in a supply system, some of the VAV boxes in the air handling. We’re making sure we create that duct run that we can inject the air seal into. That is a non-invasive process.

We like to work after-hours and on weekends so we’re not intrusive, since we do have to shut down the air handling unit for a small period of time. Our goal is that by the time everybody turns on the air handling unit for the next day of work nobody knows we were there, and the problems are all fixed.

When should Aeroseal be part of the design conversation?

We’re working really hard for Aeroseal to be part of the specifications of new buildings and in renovation. That is a great time to spec Aeroseal and make sure we’re part of that process from the very beginning so we can ensure ducts are tight.

Then if you’re working with your customers and you find any of these problems, whether it’s indoor air quality or you feel like they’re using too much energy or there are mold issues and you’re not sure where it’s coming from, Aeroseal is able to come in and do a no-risk audit to the facility and really inspect that ductwork to come up with a plan for how to fix it.

How does this work for a retrofit?

It’s difficult to go back and fix a building that’s been around for 100 years and really improve it. That is really rare. But Aerosol can do that, and in a way that doesn’t disrupt the occupants.

How does Aeroseal work with new construction?

We do this in new construction all around the world. We have a lot of work in the Middle East, where it’s so important to make sure all of those new high-rises are able to cool the occupants.

We also do a lot of new construction in the United States. For that application, it’s a lot easier because there’s not as much prep involved.

We do a lot of work with universities, for example, in classrooms and dorms. We make sure we’re diluting any contaminants [through proper ventilation] that may be there like viruses and ensure everybody in that space is getting the correct amount of fresh air but also that it’s temperature controlled, so they’re comfortable in their space as well. In a university lab environment, where you’re working with materials that are very toxic and need to be exhausted properly, that is another great application of Aeroseal.

What misconceptions exist about air sealing technology?

I get a lot of questions about whether the sealant is safe. People don’t want to put something in their nursing facility that’s going to create more problems, for example. Aeroseal has no VOCs off-gassing after it’s cured. It’s a vinyl acetate polymer, so it’s very safe. It’s the same thing used in baby pacifiers and hairspray. It’s not going to burn anyone or have any toxicity.

Another question is about longevity of the sealing. People want to know if this has to be done every year or every five years. Aeroseal has been shown to last for more than 30 years. We don’t have to come back and do it again. As long as there are no changes to the ductwork in the HVAC system, it’s a one and done kind of measure.

What does the future look like for air sealing?

People are focusing on indoor air quality in their facilities more than ever before. It’s really important. We see a lot of problems in buildings that I think before would have been brushed under the rug or put off for years. Now there really is a focus on making sure indoor air quality is safe for occupants. People are much more educated on how healthy a building should be and what impact it has on them. An educated public is really helping make sure buildings are healthy and safe for everyone involved.