Story at a glance:

- A variable refrigerant flow (VRF) system is a type of HVAC technology that uses refrigerant and variable speed controls to efficiently heat and cool a building.

- Heat recovery VRF systems allow for simultaneous heating and cooling within different zones of the same building.

- VRF systems are among the most energy-efficient HVAC technologies currently on the market.

As global temperatures continue to rise and more people are affected by urban heat islands, there’s a great need for high-quality, energy-efficient air conditioning. And while North America has long favored split system formats, another type of heating and cooling system has started to gain traction—the variable refrigerant flow, or VRF, system.

In this article we’ll provide a basic overview of variable refrigerant flow HVAC systems, including the different types and how they work, as well as their benefits and disadvantages.

What is a VRF System?

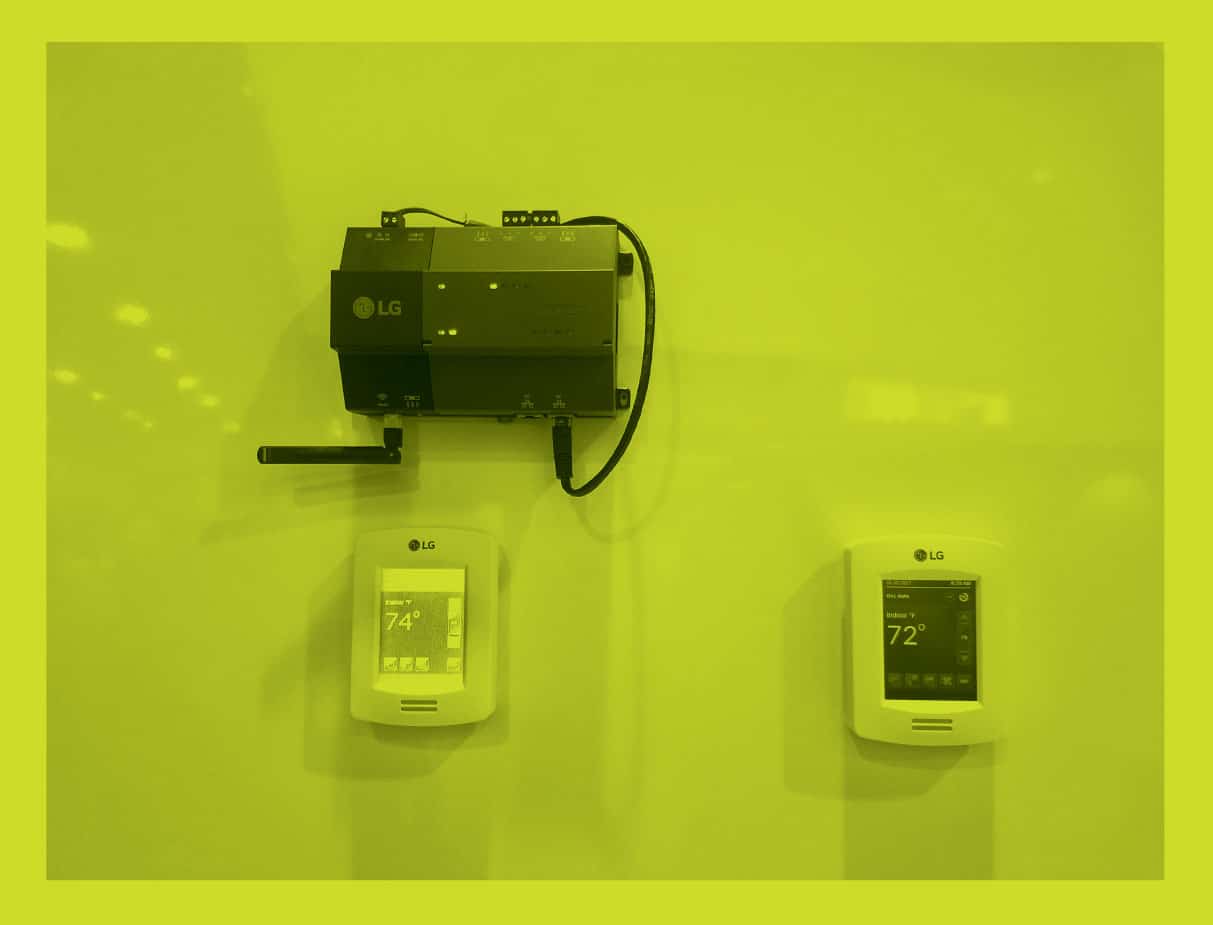

Variable refrigerant flow, or VRF, systems are a type of zoned HVAC technology that uses variable motor speeds to constantly adjust and deliver the most efficient level of heating or cooling. Photo courtesy of R.D. Olson Development

Variable refrigerant flow (VRF), also known as variable refrigerant volume, is a type of zoned HVAC technology that uses refrigerant as the primary heating and cooling medium. Developed in 1982 by Daikin Industries—a Japanese multinational conglomerate company—VRF technology is extremely popular in Asia and Europe, though it is still something of a novelty in North America.

VRF systems consist of one or more external condenser units and a series of individual indoor units, of which use an inverter to achieve a higher, more efficient level of interior temperature control.

How do VRF Systems Work?

The single most important component of a VRF system—and the part that gives it its name—is the air conditioner inverter, a device that adds what’s called a DC inverter to the compressor. This inverter enables the compressor to support variable motor speeds, which in turn enables variable refrigerant flow, allowing the system to ramp up or down based on the temperature needs within a specific zone. In comparison, non-inverter systems can only operate at full capacity and are limited to on/off operation.

“The big difference between traditional AC systems in the US and a VRF is simply that the VRF is far more technologically advanced,” Chuck Hughes, director of commercial sales for LG Air Conditioning Technologies, told gb&d in a previous article. “It’s like the difference between a computer in the 1980s and a computer in 2016.”

Instead of using ducts VRF systems rely on pipes to cycle refrigerant between an air- or water-cooled condenser unit (typically placed outside) and a series of individual indoor units. Depending on the temperature control requirements, the outdoor unit will supply each indoor unit with either subcooled liquid refrigerant or superheated gas refrigerant. The indoor units will either condense and liquefy the refrigerant gas to supply heat or vaporize the liquid refrigerant to absorb heat from the zone in question.

Types of VRF Systems

VRF systems are available in three basic configurations: two-pipe heat pump, two-pipe heat recovery, and three-pipe heat recovery. Photo courtesy of LG VRF

There are three fundamental types of VRF systems: two-pipe heat pump, two-pipe heat recovery, and three-pipe heat recovery.

Two-Pipe Heat Pump

VRF systems that utilize a two-pipe format are capable of supplying heating and cooling via the same hardware but cannot supply both heating and cooling to different zones at the same time, making use of a heat pump rather than heat recovery technology. The outdoor condensing unit in a two-pipe VRF system is connected to each indoor unit via two pipes:

- A high pressure gas refrigerant line (used for heating)

- A high pressure liquid refrigerant line (used for cooling)

When in heating mode all of the indoor units act as condensers, with the electronic expansion valve (EEV) serving to control and meter the flow of heat. This ensures an appropriate level of sub cooling as the refrigerant leaves each zone and returns via the communal return pipe to the external condensing unit. The EEV in the external unit then helps to maintain an appropriate level of superheat at the compressor intake.

Once switched over to cooling mode, each indoor unit functions as an evaporator, with the EEV serving to meter the degree of cooling and ensure the appropriate level of superheat as the refrigerant returns to the external unit.

Two-pipe VRF systems generally require more piping than three-pipe systems and as a result are often more expensive, but they also include less connections and therefore have fewer opportunities for leaks to develop. What’s more, two-pipe VRF units are altogether more flexible should system requirements change over time.

Two-Pipe Heat Recovery

Some manufacturers—like Mitsubishi and LG—do offer two-pipe heat recovery VRF systems that allow the units to supply heating and cooling simultaneously. These systems use a branch circuit controller with a liquid and gas refrigerant separator, enabling certain zones to receive heating while others receive air conditioning.

The heat extracted from zones requiring cooling is recovered and reused to help warm zones requiring heating, reducing the overall energy required to operate the system. Excess heat recovered in this manner can also be used to generate hot water; LG’s Hydro Kit is designed to do just that when paired with their Multi V VRF system:

“We also have a high-tech Hydro Kit that’s taking a receiving refrigerant, and instead of heating or cooling the air, it heats or cools the water,” Doug Bougher, director of applied sales at LG Electronics USA’s Air Conditioning Technologies division, told gb&d in a previous interview. “Now you have a VRF system that could be used like a chiller by going into more hydronic systems within the home. You could use it to cool or heat flooring, you could use it to heat a driveway, and you could even use it for domestic hot water.”

Three-Pipe Heat Recovery

A three-pipe VRF system is capable of providing heating and cooling simultaneously by way of heat recovery technology. The condenser unit in a three-pipe VRF systems is connected to an indoor heat recovery unit via three pipes:

- A high pressure gas refrigerant line (used for heating)

- A high pressure liquid refrigerant line (used for cooling)

- A low pressure gas suction line (used for returning waste heat to the condenser)

When used for heating, a zone control device opens the indoor unit to the high pressure gas line and outlet to the high pressure liquid line, wherein it acts as a condenser. If it is to be used for cooling, the zone controller opens the unit to the high pressure liquid line and provides an outlet into the low pressure gas line, acting as an evaporator. In both instances, the EEV serves to produce the required level of sub-cooling or superheating.

As with two-pipe heat recovery configurations, three-pipe heat recovery systems allow for buildings to make the most efficient use of waste heat, helping to reduce operational costs and energy loads. The main downside to three-pipe VRF systems compared to two-pipe systems is that they are less forgiving of future changes to the system design, as any alterations made after installation will impact the system in its entirety.

Types of VRF Condensing Units

A VRF system can use either an air-cooled or water-cooled condensing unit. Courtesy of PEI

VRF systems can also be loosely categorized by the type of condensing unit they use, of which there are two options: air-cooled or water-cooled.

Air-Cooled

An air-cooled or air-source VRF condensing unit is a large, refrigerator-sized device that must be installed outdoors in a space that is easily accessible for maintenance purposes. These units draw heat from outdoor ambient air.

Water-Cooled

Water-cooled or water-source VRF condensing units, on the other hand, draw heat from water and are much smaller, as water has a higher heat transfer capacity than air. This allows the condensers to be placed indoors without being intrusive. “It heats or cools air right where it’s needed,” Patrick Barry, US senior manager of air conditioning product development at LG, told gb&d. “It’s directly analogous to a tankless water heater.”

Water-cooled condensing units can even be linked to a geothermal well system for improved energy efficiency.

Benefits of VRF Systems

The benefits of VRF systems include improved energy efficiency, quiet operation, a high level of temperature control, and more. Photo courtesy of LG Electronics USA

While they are most known for their high level of energy efficiency, VRF systems offer a host of additional benefits as well, including:

Energy Efficiency

The most significant benefit that comes with the installation of a VRF system is the improved energy efficiency it offers over many other types of HVAC technology. Compared to ASHRAE standard 90.1 rooftop units, VRF systems operate 40 to 50% more efficiently—a feat achieved in large part thanks to their ability to run only at the speed necessary to meet demand.

Heat pump and heat recovery heating are also much more energy-efficient than electric heating. LG’s Multi VTM 5 VRF units, for example, utilize heat pump technology to achieve their high level of efficiency. “Electric heat has a COP (coefficient of performance) rating of 1.0 while our heating systems achieve a higher COP, which means a more energy-efficient rating of 3 to 4 depending on the size because we are using inverter compressions and heat pump heating,” Ed Ferrier, senior manager of engineering for LG Air Conditioning Technologies USA, told gb&d in a previous interview.

Another driver of VRF systems’ impressive energy efficiency is the fact that they do not rely on ducts to transport and deliver warm or cool air throughout a building. Air loss through ducts can account for up to 30% of HVAC energy consumption, according to the DOE’s Energy Saver reports.

And while it’s true that all types of VRF systems are efficient, heat recovery systems are considered the most energy-efficient of them all, as they allow waste heat to be recycled for continued use.

BMS Integration

In 2017 LG debuted its MultiSITE system with the smallest footprint, largest capacity single frame VRF model on the market. Photo courtesy of LG

While it used to be much trickier, contemporary VRF technology supports straightforward integration into an existing building management system (BMS). LG, for example, developed the LG MultiSITE suite of smart controls for their revolutionary Multi V 5, the smallest footprint, largest capacity single frame VRF model on the market.

“For the first time ever designers can implement VRF technology directly into an existing BMS through an intuitive platform,” Kevin McNamara, senior vice president and general manager of air conditioning technologies for LG Electronics USA, previously told gb&d. “This is a huge shift in the way VRF technology has been incorporated into building management systems.”

High Level of Temperature Control

Another benefit of VRF systems is the high level of temperature control they offer to building occupants. This is because VRFs operate using a zone-based network of individual indoor units, each of which is equipped with its own thermostat and set of controls.

VRF systems that utilize heat recovery technology offer an even more impressive level of climate control, as they allow heating and cooling to be supplied to different areas at the same time. This feature can be extremely beneficial in, say, a large restaurant during the winter months, as it enables the lobby and dining areas to be kept warm for patrons while also keeping the kitchen—already warmed by ovens, stoves, and the like—cool for the cooks and waitstaff, or in an office building with a main server room that needs to be kept cool year-round.

Quiet Operation

A VRF system supplies the Lido House seaside resort with quiet, comfortable heating and cooling, allowing guests to focus on having a peaceful vacation. Photo courtesy of R.D. Olson Development

One advantage of VRF systems that often flies under the radar is how quiet they operate. This is primarily due to the nature and placement of the condenser units they use—air-cooled VRF systems, for example, are quieter because the noisy condenser unit is typically placed outside, whereas the smaller water-cooled condenser units are naturally quieter due to the technology they use.

It was partially due to this extremely quiet operation that R.D. Olson Development chose to install a VRF system in the Lido House, a cozy seaside resort in Newport Beach that is part of Marriott’s Autograph Collection.

“Because of its reliability and flexibility as well as the fact that it’s extremely quiet, LG’s VRF provides a level of comfort that our guests expect,” Dennis Reyling, vice president of construction and development for R.D. Olson Development, previously told gb&d. “Because it’s basically operating at a level the guests aren’t even aware of, they are left undistracted to enjoy the Lido House experience, which celebrates everything that’s special about the Newport Beach coastal lifestyle. That’s where we want their focus, and LG’s VRF allows us to keep it there.”

Challenges of VRF Systems

Despite these many benefits, VRF systems are not without their challenges either, of which include:

Higher Upfront Costs

Because they require specialized components and are altogether more complex than traditional HVAC systems, VRF systems come with a high upfront cost. Of course, like with any energy-efficient device, the high upfront costs of VRFs are typically justified by their lifetime reduction in energy consumption.

Specialized Maintenance

While not a particularly egregious disadvantage, the fact that VRF systems require specialized maintenance shouldn’t be overlooked, either. Many HVAC technicians do not possess the necessary knowledge, training, or experience required to properly maintain VRF systems, meaning it may be more difficult to find a reliable maintenance professional.

It can also be difficult to access certain components of a VRF system—namely the refrigerant piping network—should they break. Altogether, this means that VRF system maintenance is often more expensive than traditional HVAC maintenance, resulting in higher costs for building operators.

Potential for Leaks

Because they use refrigerant as their heat exchange medium, it is possible for VRF systems to develop leaks over time should a specific part degrade or break, resulting in reduced efficiency, increased energy consumption, and potentially even safety or environmental concerns.