Story at a glance:

- With proper planning, using flexible building materials can help you earn LEED points and prolong a structure’s operational lifespan.

- Fabric structures offer a flexible alternative to more permanent divisions.

- Acoustic panels are another flexible option, allowing designers to design for different acoustic needs.

What is design for flexibility? The USGBC defines design for flexibility, which can earn you a LEED point, as designing to “conserve resources associated with the construction and management of buildings by designing for flexibility and ease of future adaptation and for the service life of components and assemblies.”

Flexible building materials are one part of designing for flexibility, and they run the gamut from movable walls and glass partitions to fabric structures and acoustic panels.

14 Examples of Flexible Building Materials & Products

Here are 14 flexible building materials and products straight from industry experts—plus how to best use them.

1. Wide-Span Framing Systems

Photo by James Brittain Photography

An open floor plan is one of the hallmarks of flexible design, one that is often made possible through the use of large-span, clear-span, and space frame systems. Large-span framing systems, for example, use long span beams to greatly reduce the amount of intermediate columns needed for structural support, whereas clear-span framing systems are entirely self-supporting steel structures and do not require any columns at all.

Space frames, on the other hand, are rigid, lightweight, truss-like structures that utilizes interlocking struts arranged in geometric patterns to provide a high degree of structural support without the need for numerous load-bearing walls and columns in the building’s center. Space frames are typically made from steel, but can also be made from a combination of building steel and concrete.

A large-span framing system was just one of many flexible design elements included in Calgary’s 9th Avenue Parkade, a modern parking garage designed by Kasian Architecture and 5468796 Architecture to remain useful even as societal attitudes move away from oil-based vehicles.

“Having an adaptable frame is the foundation for developing an adaptable building,” Joanne Sparks, associate and project architect at Kasian Architecture, Interior Design, and Planning, wrote in a previous gb&d article. “Utilizing a post-and-beam system with large spans, provides a grid that maximizes a floor plate for future development. This system, absent of intermediate columns and coupled with the expanded floor-to-floor height, allows for a variety of future uses without having to compromise on the interior layout.”

Pro: Creates large, open layouts free from obstructions like columns that might limit future uses

Con: Higher costs and technical requirements

Best Use: Mixed-use building projects, sports facilities, and warehouses

2. Staggered Floor Plates

Combined with an offset cantilevered core made of glass, the structural system allows for large, open floor plates and flexible, light-filled workspaces at 800 Fulton Market, designed by SOM. Photo by Dave Burk

Massive floor plates have become the norm over the past several decades—and though they may be desirable to certain clients, like Google and other major tech companies, they make it harder for buildings to evolve and take on new functions over time. And while it may be tempting to say that smaller, narrower floor plates are best when it comes to ensuring long-term flexibility, incorporating staggered or stepped floor plates of different dimensions can be even more beneficial.

Indeed, floor plates were a core part of the conversation in SOM’s design of 800 Fulton Market, a mixed-use office building located in the heart of a historic Chicago neighborhood. In pursuit of flexibility, the team elected to go against the market’s obsession with massive floor plates, choosing instead to design a series of setbacks and landscaped terraces that meshed better with the scale of the surrounding community.

“That’s part of why we started stepping the building,” Kevin Rodenkirch, associate principal at SOM, previously told gb&d. “That 60-foot clear zone is consistent all the way up so you always have the space. It allows a lot of room to change with it, and then as you march up the building the floor plates are different so you have a super flexible building, but you can still have a 35,000-square-foot floor plate near the bottom.”

Pro: Helps bring daylight into all floors

Con: May not always be the most efficient use of space

Best Use: Mixed-use buildings in dense urban areas

3. Raised Access Floors

The Boulevard at Orlando International Airport Terminal C is characterized by its continuous skylight of varying blue frits that expresses the design themes of sky, water, and flora. This project also included a large application of raised access flooring to help with any future needs for the airport to adapt. Photo by Michael Robinson

In the digital age the ability to quickly and easily adapt or update a building’s technological capabilities is priceless—and raised access floors can help a building do just that. Raised access floors consist of an elevated floor built above a building’s original concrete slab and provide additional hidden space for piping, cables, wires, and even airflow.

Without raised access flooring, expanding a building’s data network or integrating a new kiosk would require core drilling through the floor slab and running the new cable horizontally through the ceiling below the floor above—a process that is expensive, disruptive, and time-consuming. With raised floors all you have to do is pick up a panel, pull cable out, plug it in, and put the panel back in place.

“You can move them around. It’s way less cost of change, and, because nobody knows exactly what the future is going to call for, you’re future-proofing that design,” Mark Johnson, commercial sales director at Tate Access Floors, told gb&d in a previous article. “In terms of the installation, raised floor makes all of the other components easier to install. It accelerates the construction, shortens the construction schedule, and allows people to move in quicker.”

The new Fentress-designed Terminal C at Orlando International Airport takes full advantage of the inherent flexibility of raised access floors. “We made the entire area where you go through TSA all on raised floor,” Curtis Fentress, founder and principal-in-charge of design at Fentress Architects, previously told gb&d. “We had proposed that on many airport projects previously because we saw that changes were in the pipeline for the industry—and many more to come, of course, with advances in technology. They agreed to it in Orlando, and so it was much, much easier to do the first installation.”

Pro: Provides easy access for maintenance and simplifies future updates to a building’s technological capabilities

Con: Added installation complexity and the potential for vibration issues

Best Use: Airports, data centers, telecommunication facilities, commercial office buildings, and computer rooms

4. Glass Partitions

Demountable partitions made of aluminum and glass are a sustainable alternative to traditional drywall. Demountable systems can also be reconfigured and reinstalled, reducing the amount of materials used and lowering your overall carbon footprint. Photo courtesy of Transwall

Glass office fronts are a beautiful and sustainable option for projects, as they’re both recyclable and reusable. “Demountable by nature, many office fronts can be installed, taken down, reconfigured, and installed again—allowing companies to breathe new life to their office layout while saving money and reducing waste,” said Marc Valois, executive vice president and principal of Transwall, in a previous submission to gb&d.

Valois writes that glass and aluminum—the materials required for glass office fronts—are some of the best and easiest materials to recycle. “Glass is 100% recyclable and can be recycled endlessly without loss of quality or purity. Aluminum is one of the most efficient and widely recycled materials. Recycling aluminum saves 95% of the energy cost of processing new aluminum,” he said.

Aside from traditional glass fronts, partnering with other demountable systems for demising walls can increase the flexibility of the built space while providing a sustainable alternative to drywall at the same time, Valois said.

Pro: Demountable by nature; more natural light

Con: Reduced privacy; more distractions

Best Use: Evolving office spaces

5. Operable Wall Systems

Skyfold allowed this SAP Digital Leadership Center to have many types of meeting rooms running independently and simultaneously. Photo courtesy of Skyfold

Similarly, operable walls are another of the flexible building materials whose benefits may be obvious but should not be understated. “Movable walls are fundamental to creating a dynamic, flexible workspace,” Bryan Welch, managing director at Modernfold, a top producer of operable walls, previously told gb&d.

Modernfold’s Acousti-Clear Glass Walls product line, for example, is one of their most popular and comes in motorized, automated, and demountable options. The system’s glass walls allow rooms to make effective use of daylight for illumination and can be equipped with blinds, roller shades, or even Modernfold’s MorphGlas technology—which turns the clear panels opaque at the push of a button—for increased privacy.

And while it’s recommended that operable walls be considered early on in the design process to ensure they are properly supported by structural steel elements, Modernfold also offers options that are much more retrofit-friendly. Their truss system, for instance, completely eliminates the need for overhead support and can be installed almost anywhere.

“The Modernfold truss system easily fits into most plenum spaces, so that can be one important piece that will make it easier on a retrofit where structural steel may not have been in place before. We’ve definitely seen advantages to being able to offer that turnkey solution in a renovation project,” Welch says.

There are also mechanical wall systems that operate from the top down. Skyfold is a leading manufacturer of such systems, offering a range of vertical folding retractable walls that disappear into the ceiling at the push of a button. “It can be deployed quickly, easily, and safely with very minimum effort,” Alastair Cush, managing director at Skyfold, previously told gb&d. “Its most obvious use case is that a meeting room can be divided into small meeting rooms within minutes without any labor. It allows for more dynamic management of space and probably a more efficient and profitable use of space.”

Pro: Movable; improved acoustics

Con: Sizable investment

Best Use: Commercial offices, co-working spaces, and conference halls

6. Portable Room Dividers & Partitions

Screenflex portable dividers are quick and easy to set up in any desired configuration. Courtesy of Screenflex

Talk about fast flexibility. Solutions like the portable room dividers offered by Screenflex allow you to quickly transform spaces as needed—with durability and peace of mind.

Screenflex Vice President Rich Maas previously told gb&d that Screenflex portable room dividers allow you to reconfigure any space in minutes. “In the workplace, our solutions help teams quickly and efficiently make training rooms, set up private interview spaces, or even prepare for blood drives. We’ve seen all of these scenarios and more,” he said. “This flexibility in design is more important now than ever, as many workplaces seek solutions for social distancing, too.”

Screenflex solutions are easy to operate and store with a compact storage feature. They are built to last, too, thanks to self-leveling casters, locking corner casters, and full-length hinges connecting each panel to the adjacent panels. A durable steel end frame adds to their sturdiness.

For spaces that require acoustic control in addition to privacy, Arktura—a leading provider of innovative, sustainable acoustic solutions—offers a variety of suitable products. All of their SoftScreen partitions, for example, can be mounted on sliding tracks to divide spaces when necessary and provide varying levels of acoustic control depending on whether the client chooses a solid, half, or full pattern design.

Pro: Quickly movable

Con: Limited aesthetic options

Best Use: Spaces that need to quickly change over

7. Fabric Structures

Photo courtesy of Shelter-Rite Architectural Fabrics

Fabric structures reduce construction and installation time, according to Frank Bradenburg of Shelter-Rite Architectural Fabrics.

In a previous gb&d article, Bradenburg explains how fabric structures offer permanent, seasonal, or relocatable options, though he says most architectural fabric structure designs are meant to be permanent. “They can have an internal metal frame, use an internal mast and cables, or use only air to support the architectural fabric skin. The architectural fabric itself can last 20 to 30 years and be replaced with a new skin after that time, just like shingles or single-ply roof membrane. The metal frames, masts, and cables will last 50-plus years. Permanent fabric structures are frequently insulated with fiberglass or other lightweight insulation and must meet all local fire and safety codes, just like conventional buildings.”

However, he says one great benefit of architectural fabric structures is their ability to be designed as seasonal or semi-permanent structures. “Air-supported fabric structures can easily install over artificial sports turf fields to provide a recreational facility during the winter. The structures can come down in the spring and stored for the following season.”

Pro: Affordable; easy and fast to install

Con: Air-supported structures must maintain a positive internal air pressure inside, requiring air locks to enter and exit the structure.

Best Use: Year-round sports and recreation facilities

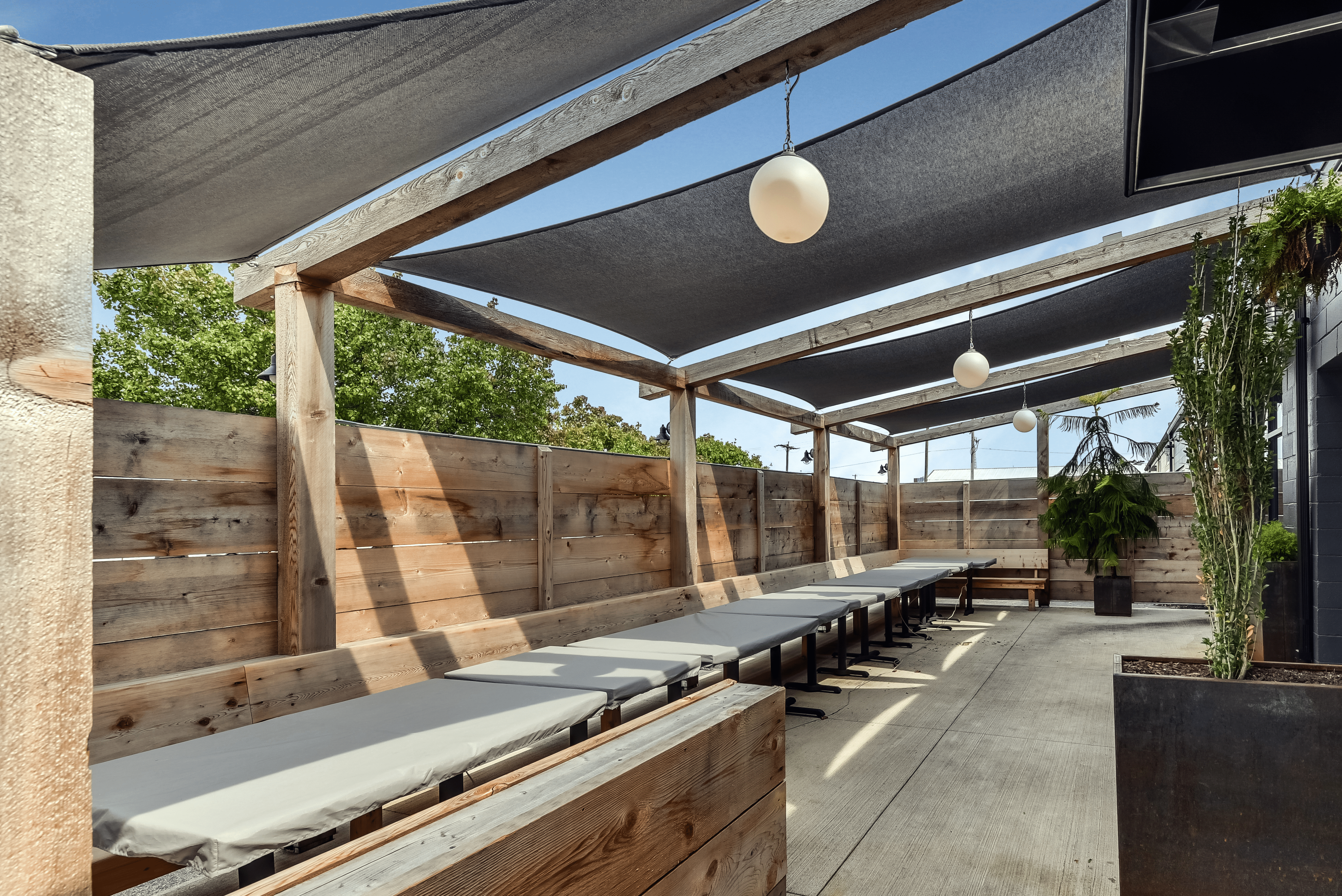

8. Shade Sails

Sunbrella helped to transform this Columbus, Ohio, eatery. Photo courtesy of Sunbrella

Perhaps similarly but varied in scale, Sunbrella manufactures high-end performance fabrics like those used in shade sails—delivering durable, changeable designs in compelling styles.

Sometimes considering a shade structure isn’t top of mind for some design professionals, but when it comes to flexible building materials it should be, according to Vince Hankins, Sunbrella’s industrial business manager, in a previous article for gb&d. “It can enhance the facade. It can enhance the overall campus and site layout. It’s flexible. It can change and evolve. It can be styled over the lifespan of the building.”

Pro: High-performance; aesthetic options

Con: Customizing for best use can be costly.

Best Use: Restaurants and patios

9. Adjustable Furniture

Learning environments benefit from flexible furniture setups and biophilic design strategies, as seen in this rendering by MooreCo. Rendering courtesy of MooreCo

Similar to movable walls and partitions, mobile and adjustable furniture is capable of providing a high level of flexibility by accommodating a variety of configurations and uses at a moment’s notice. Educational spaces, for example, can greatly benefit from the inclusion of adjustable furniture options, though it is these spaces in which such furniture is often absent—something that MooreCo is working to change.

A leading manufacturer of flexible, innovative furnishings, MooreCo’s designs are driven by a philosophy they call Thrive, which explores how indoor environments impact human health and happiness. Their Porcelain Steel Hierarchy Shapes Desk, for example, is adjustable and features a built-in porcelain steel dry-erase top that students can use for note-taking, drawing, brainstorming, and more.

Architectural firms like DLR Group recognize that this degree of flexibility is crucial for successful classroom design. “Having that choice—soft seating, high-top desks, tables. All of that mixed in a classroom environment gives the autonomy to learn where you learn best or engage the best,” Ian Kilpatrick, principal K-12 education design leader for DLR Group, previously told gb&d. “At the end of the day, we’ll see 12 to 15 different pieces of furniture in a lot of our classroom environments, and that helps a lot.”

Pro: Contributes to earning a LEED point

Con: Design consistency

Best Use: Commercial offices, educational facilities, and health care buildings that must accommodate a wide range of user preferences

10. Movable Casework

Gensler’s Seattle office features both moveable casework and mobile furniture. Photo by Heywood Chan Photography

Beyond furniture, the USGBC also suggests considering movable or modular options for at least 50% of all casework and custom millwork in projects. They advise that you base the calculation on the combined value of casework and millwork, as determined by the cost estimator or contractor.

When Gensler redesigned their Seattle office, mobile casework was a key component in ensuring the building’s long-term functionality. Plywood paneling installed along the back wall gives the office the impression of a workshop, but the pre-drilled peg holes are what really make it flexible, allowing shelving to be added or moved to accommodate changing needs with ease.

“You’re not seeing really expensive wall materials and such. And the movable shelving can live and change over time in terms of what’s on the walls, what’s on the shelf, what’s important to staff, what’s relevant,” Ryan Haines, a managing director at Gensler Seattle, told gb&d in a previous interview. “It’s a much more flexible, non-precious aesthetic overall. Everything is on wheels in the whole space—including in the kitchen.”

Kimball International—a leading omnichannel commercial furnishings company—offers modular casework solutions in the form of Alterna, a line whose products are designed to accommodate flexibility in health care spaces. “We can design such that the casework will adapt and change for any future need,” Kim Montague, executive director of applied research and partnerships at Kimball International, previously told gb&d. “You can design it with space for a monitor to be put on the wall to accommodate a virtual care encounter.”

Pro: Ease of installation and reconfiguration

Con: Can be expensive depending on the level of customization

Best Use: Universities, laboratories, and health-care facilities

11. Precast Concrete Wall Panels

Fabcon’s precast concrete wall panels save projects time and money while being ultra durable and efficient. Photo courtesy of Fabcon

Precast allows flexibility for expanding and modifying existing buildings. With Fabcon’s precast concrete panels, you can do everything from add a pedestrian door to remove 75% of a wall. Precast concrete walls can be designed to be reused for future building expansions.

“Fabcon can establish a larger completed footprint in a shorter amount of time,” George Miks, director of engineering at Fabcon, told gb&d in a previous article. “If you think of a masonry wall, what they send out to the site are a bunch of blocks that have to be assembled and constructed out in the field.” When Fabcon sends panels to the job site, the pieces are ready to install.

As a result, some companies are able to open their doors for business months in advance, Miks says, which is much faster than construction methods like block or stud frame. If things go smoothly out in the field, Fabcon can install 20 to 30 eight-foot panels in a day.

Pro: Saves construction time

Con: High initial investment

Best Use: Any modular construction project or building that needs to go up quickly

12. Acoustic Panels

Photo courtesy of FSorb

Acoustic panels like the solutions offered by FSorb give designers the chance to further customize a space while implementing situational acoustic design.

“With the trend for open ceilings and a lack of physical barriers or walls, acoustical treatments need to satisfy the needs of the people residing within the space,” wrote Doug Bixel in a previous submission to gb&d. “In an office setting, it is common for teams to work on a particular project for a period of time. These teams are often situated with another team next to them. Their ability to be heard within their own team and not be distracted by the adjoining team is critical. As I examined this trend, I found that ceiling materials can be placed directly overhead of these noisy areas in patterns that diffuse and block the sound coming from the neighboring team.”

Bixel said this situational acoustic design approach—where panels are placed in targeted noisy areas—can create a nice break in sound from one space to the next, absorbing the sound where the noise source is.

And the solutions themselves are flexible. “By positioning acoustical screens between working spaces and common spaces, a physical barrier can also come into play. Acoustical screens with negative space patterns cut into them provide great absorption from both sides while still allowing light to flow through,” he said. “They can be suspended on a track system so that they can separate spaces where users can change the feel by simply rearranging panels.”

Pro: Allows for situational acoustic design

Con: Often need expert installation

Best Use: Office environments with varied employee needs, like group meetings, focused work, interviews, etc.

13. Aluminum

Aluminum is a versatile and sturdy building material that helps structures meet their energy efficiency goals. With significant design flexibility and applications everywhere from building frames and all terrain staircases to windows and doors, aluminum is a cost-effective option to have in mind for future projects. “We use architectural metal, things like aluminum panels, on virtually every project,” Rodenkirch says.

You can see one example of aluminum in action at Hewitt, which uses aluminum for their all-terrain staircases because it’s lighter than steel and wood but just as durable and even easier to work with, said Chris Shay, Hewitt’s sales manager, in a previous gb&d article.

While all-terrain stairs are commonly used in rural settings, there’s a growing demand for urban applications, too. “If you have a living quarters above a garage, or a second story on an apartment building or commercial complex, the all-terrain stairs are a more flexible and cost-effective solution than steel or wood stairs,” Shay said.

Pro: Aluminum is 100% recyclable and easily customizable.

Con: Not traditionally energy-efficient—requires modern technologies to work at its best

Best Use: Anywhere wood could be used but that requires more long-term durability and fire safety without significant maintenance

14. LED Lighting

Lumenomics designed, installed, programmed, and commissioned the lighting system at ATLAS Workbase—a coworking space in Seattle that enables occupants to work and connect efficiently while maintaining a connection to the outdoors. Photo courtesy of lumenomics

The structure of LED lights allows them to be used both functionally and artistically, making them another one of those flexible building materials that can offer design flexibility in spaces of all kinds. This is amplified by the fact that LEDs are available in a range of colors, color temperatures, and brightness levels, with many providing the option for dimmer compatibility—making them ideal for spaces that must accommodate a range of user preferences.

When it comes to LEDs and lighting controls, Marti Hoffer—founder and CEO of lumenomics—previously wrote for gb&d that: “A truly occupant-centric smart lighting system should mimic the natural lighting pattern through tunable and dimmable LED fixtures to reinforce occupants’ circadian rhythm, with meaningful control systems to ensure ease of understanding and use for occupants.”

And in addition to being highly flexible, LED lights are also extremely sustainable, operating up to 90% more efficiently than conventional incandescent or fluorescent bulbs. LEDs also have a much longer lifespan than incandescent bulbs—up to 30x longer, in fact—cutting maintenance expenses and reducing a project’s overall waste production.

Pro: Long-lasting with many aesthetic options

Con: Not always dimmer compatible

Best Use: Industrial and commercial projects

Laura Rote contributed to this article.