Story at a glance:

- People can be exposed to an unhealthy amount of noise pollution, but acoustic insulation can combat this.

- The demand for acoustic insulation and products has increased over the past decade.

- There are several types of acoustic insulation ranging from stone wool and fiberglass insulation to soundproof drywall and cork underlayments.

Noise pollution can have a significant impact on people’s health. Those living and working in cities are especially vulnerable. The World Health Organization (WHO) estimates that about 40% of the European Union’s population is exposed to road traffic noise with an equivalent sound pressure level exceeding a healthy amount. At night more than 30% are exposed to noise levels that are disturbing to sleep.

Controlling outside noise isn’t always possible, but acoustic insulation can offer valuable solutions. Acoustic insulation can be especially useful when installed in separating floors and walls between spaces in a block of apartments or an office building. Sound insulation boards or granulate can also be applied to reduce the noise coming into an environment, according to the experts at ROCKWOOL, a manufacturer of stone wool insulation.

There are a wide variety of products out there, ranging from ceiling baffles to panels and partitions. This guide to the types of acoustic insulation solutions includes the many sustainable options and how you might use them.

What is Acoustic Insulation?

Acoustic insulation refers to those products designed to block sound transmission within a structure. Photo courtesy of Greenfiber

Controlling the acoustics of the built environment is done by either absorbing or blocking sound, with acoustic insulation designed to perform the latter. Also referred to as sound insulation, acoustic insulation is a term used to describe those materials, products, and systems designed to prevent the transference of sound waves between walls, floors, ceilings, and other building components.

Generally speaking, the most effective means of reducing sound transmission is by increasing the mass of the partition in question, something that is typically achieved through the addition of dense, non-porous materials. This makes it much more difficult for the sound waves to pass through the structure.

Acoustic Treatments vs Acoustic Insulation

Before we move on, let’s take a moment to clear up some confusion and talk about the difference between acoustic treatments and acoustic insulation, as the two are often used interchangeably despite referring to two completely different things.

Acoustic treatments describe those products whose core purpose is to change the dynamics of how sound moves within a space. Most acoustic treatments are designed to either absorb or redirect sound waves—qualities that help improve sound within the space itself, but which do not in and of themselves block sound transmission between rooms. Acoustic treatments may help dampen sound, but they will not prevent that sound from traveling through a building’s walls, floors, or ceilings.

Acoustic insulation, on the other hand, is specifically designed to reduce sound transmission and prevent sound from bleeding into or out of a space. Most design plans include a combination of both acoustic treatments and acoustic insulation to reduce the transmission of unwanted direct sounds and control desired sounds.

Understanding Sound Transmission

Photo courtesy of National Gypsum Company

Now that we’ve a better understanding of what acoustic insulation is—and what it isn’t—let’s briefly explore the three major types of sound transmission that acoustic insulation is designed to prevent: airborne noise, impact noise, and flanking noise.

Airborne Noise

Airborne noise describes those sounds whose vibrations are transmitted through the air. This includes those sounds produced by talking, sounds from radio and television, vehicle-related sounds, and more. It is typically easier to block out airborne noise in comparison to impact noise, but the former is often more prevalent, occurring anywhere there is a leak, gap, crack, or some other opening in a wall, floor, or ceiling.

Impact Noise

Impact or structure-borne noise, on the other hand, refers to sound created by impacts on a specific building component, typically the floor. Impact noises are stronger than airborne noises and are capable of traveling further through dense materials, making them the more difficult of the two to isolate. Common examples of impact noises include footsteps, doors closing, furniture moving, et cetera.

Flanking Noise

Finally, flanking noise describes any noise that reaches a room by way of an indirect path—that is, other than through a wall or floor/ceiling assembly. Flanking noise occurs when a sound becomes structure-borne and finds a path around an isolated surface, such as through windows, fixtures, outlets, plumbing chases, structural joints, floor joists, wall and ceiling junctures, and so on.

Acoustic Insulation Ratings

A product’s sound transmission class rating is the most important to consider when choosing acoustic insulation. Photo by Todd Wilson Images

There are several ratings that provide valuable information as to the specific qualities of acoustic insulation systems and assemblies: the sound transmission class, impact insulation class, ceiling attenuation class, and noise reduction coefficient.

Sound Transmission Class

As the most important rating when it comes to choosing acoustic insulation, the sound transmission class (STC) refers to a material’s ability to effectively block airborne noise from traveling between building partitions. STC is calculated by finding a room’s transmission loss (TL) values tested at sixteen standard frequencies between the range of 125 Hz and 4,000 Hz and plotting them on a graph. TL values are measured in decibels (dB) and figured by measuring the decibel sound transmission loss in the receiving room compared to the sound pressure level in the source room.

There are six STC values that are used to gauge how well a material or building assembly blocks sound:

- 25 (Soft speech can be heard)

- 30 (Normal speech can be heard)

- 35 (Loud speech can be heard)

- 40 (Loud speech can still be heard, but is unintelligible)

- 50 (Loud sounds can be faintly heard)

- 60+ (Considered the minimum for true soundproofing)

A space is typically considered quiet if it has an STC 40 rating, though the International Building Code (IBC) recommends a rating of STC 50 for walls, floors, and ceilings as a minimum requirement, with STC 55 to STC 60+ being the ideal. For reference, a standard 2×4 wood stud wall with ½ inch of drywall on each side and no insulation has a baseline STC rating of roughly 34.

Impact Insulation Class

Derived from ASTM method E989, impact insulation class (IIC) is an integer-number rating system designed to communicate how well floor and ceiling systems in multilevel buildings attenuate impact sounds. An IIC rating is calculated based on sound attenuation values tested at sixteen standard frequencies ranging between 100 and 3,150 Hz. Ratings themselves range between 50 and 85+, with higher numbers indicating an increased ability to block out impact noise.

An IIC rating of at least 65 represents the point at which heel clicks begin to become inaudible and is generally considered the minimum for true soundproofing.

Ceiling Attenuation Class

Ceiling attenuation class (CAC) is a measure for rating ceiling systems’ effectiveness at blocking airborne sound transmission between adjacent rooms that share a common air plenum where the wall does not extend to the deck itself. The system was specifically designed to rate the sound attenuation of suspended ceiling systems and is functionally the same as the STC rating system.

CAC ratings range from CAC 25 to CAC 50, with a higher rating representing an increased ability to prevent noise transmission; as a general rule, ceilings with a CAC rating of at least 35 are considered to be highly effective.

Noise Reduction Coefficient

The noise reduction coefficient (NCR) is a single-number value ranging from 0.0 to 1.0 that describes how well a material or product reflects or absorbs sounds. A low NCR indicates that a material reflects rather than absorbs sound energy, whereas a high NCR is to be expected of products like acoustic panels that are specifically designed to absorb sound.

In the practical sense, an NRC rating speaks more to a building component’s ability to absorb sound than block sound, but it can still be useful when considering different acoustic insulation products.

Types of Acoustic Insulation

There are many types of acoustic insulation strategies that may be employed throughout a building to reduce the transfer of airborne, impact, and flanking sounds between partitions and other building assemblies.

Stone Wool Insulation

Photo courtesy of Rockwool, Getty Images

Also known as mineral wool, stone wool insulation is one of the most widely-used forms of acoustic insulation on the market. Stone wool is created by spinning molten rock and minerals with steel slag to create a wool product. Pressed into rolls and sheets, stone wool creates an incredibly effective insulation with sound-absorbing and fire-resistant properties.

ROCKWOOL is a leading provider of stone wool insulation solutions, including those specifically designed to provide additional soundproofing. ROCKWOOL’s sound insulation can be applied using acoustic insulation rolls, slabs, boards, granulates, or batts. After building a stud wall frame, stone wool insulation can easily be slotted between the studs to reduce sound transmission between adjacent rooms.

When installed in interior wall assemblies consisting of 2×4 wooden wall studs spaced 16 inches apart using a double stud wall configuration and a ⅝ inch type X gypsum finish, 3 ½ inches of ROCKWOOL Comfortbatt can help wall assemblies achieve an STC 60 rating. ROCKWOOL AFB, on the other hand, is designed for interior steel stud wall assemblies and can deliver up to a STC 57 rating depending on the wall’s components.

Aside from helping to reduce sound transmission, stone wool insulation is also a highly sustainable option compared to other insulation materials. “It’s right there in the name. Our products are made from stone—the most abundant natural resource on earth and fully recyclable. You might hear us talk about harnessing the natural power of stone; that’s because our stone wool insulation carries many of the same properties as the raw material. They are lasting, durable, and resilient,” Sophia Rini, director of public affairs and communications of ROCKWOOL, told gb&d in a previous contribution.

ROCKWOOL products are also tested by five third-party certifying bodies including: UL, Intertek, QAI, ICC-ES, and FM. Many stone wool insulation products from the company are also GREENGUARD Gold–Certified, a designation that places stringent limits on emissions of more than 360 volatile organic compounds.

Fiberglass Insulation

As perhaps the most widely used type of thermal insulation, fiberglass also has commendable noise reduction properties as well. Created by either spinning or blowing molten glass and then spraying it with adhesives, fiberglass insulation functions similarly to stone wool by acting as a barrier and effectively prevents some sounds from passing through a partition.

Generally speaking, fiberglass insulation can elevate the STC rating of a standard wood-framed drywalled wall assembly from 34 to 39. Fiberglass insulation is available in roll or batt form and can be installed in vents, around pipes, and inside partitions.

Wood-Fiber Cellulose Insulation

Greenfiber’s wall insulation starts as a plant material, is made into paper, and reused as insulation. Photo courtesy of Greenfiber

Wood-fiber cellulose is another common type of acoustic insulation that is derived from recycled paper. Cellulose insulations can be blown-in or spray-applied to multiple types of walls, floors, and ceilings.

When used in a standard wall assembly consisting of single woods studs, resilient channels, and a single layer of ½ inch gypsum drywall on each side, a 3 ½ inch layer of R-13 cellulose insulation raises the assembly’s STC rating to approximately 51, outclassing both fiberglass batts and open-cell spray foam insulation.

“That’s the beauty of the product. External sounds like your neighbor having a party or working on the lawn will be mitigated when a house has all the exterior walls done,” Luke Shortridge, market development manager for Greenfiber’s Southwest region, previously told gb&d. “And then the interior walls are for the inhabitants to be able to do what they want in their separate areas of the room.”

In addition to reducing sound transmission, wood-fiber cellulose is also a highly sustainable type of acoustic insulation. Greenfiber uses a low-energy manufacturing process for its insulation products and reuses upcycled paper during production—a practice that has diverted approximately 160,000 tons of paper from landfills.

Gypsum & Soundproof Drywall

Most of National Gypsum’s PURPLE products are available nationwide, either in stock at major stores or easy to order and arrive within days. Photo courtesy of National Gypsum

Reducing noise transmission is also possible with gypsum and gypsum-based products like soundproof drywall. National Gypsum—a leading provider of gypsum board and drywall products—for example, carries a range of acoustic insulation products designed to reduce unwanted noise transmission. Their SoundBreak line was intentionally designed to stop noise from bleeding through to other rooms without the need for any prior demolition.

These include the SoundBreak XP Wall Board, which is installed between walls and can help protect your walls against moisture, mold, and mildew. Another noteworthy sound board is the SoundBreak XP Retrofit Board, which allows users to apply it over existing walls.

“SoundBreak XP offers superior sound damping to keep noise out, so it’s perfect between hotel rooms, office spaces, doctors’ offices, and more. This line includes a Retrofit product with all of the same benefits as SoundBreak XP, but that reduces waste, too,” John Bianchi, National Gypsum system products manager, wrote in a previous gb&d article.

National Gypsum also offers its SoundBreak XP Ceiling Board that reduces noise between floors. “All of our SoundBreak products perform really well with high-pitched noises like voices and TVs, but the ceiling board is even thicker—it’s about three-quarters of an inch—and it’s for floor-ceiling assemblies,” writes Bianchi. “Let’s say you have a hardwood floor on top of a living area in a multi-family application. If someone is wearing high heels overhead, this panel does a phenomenal job of dispersing that sound and making it less audible down below.”

The STC rating of gypsum-based wall assemblies can be improved upon further through the use of various decoupling strategies. “Decoupling can be achieved by constructing wall assemblies that have staggered studs, two rows of studs, or resilient channels to break up the sound’s path of travel into adjacent spaces.” Matt Gallagher, product manager of gypsum systems at National Gypsum, told gb&d in a previous interview.

Floating Floors & Acoustic Underlayments

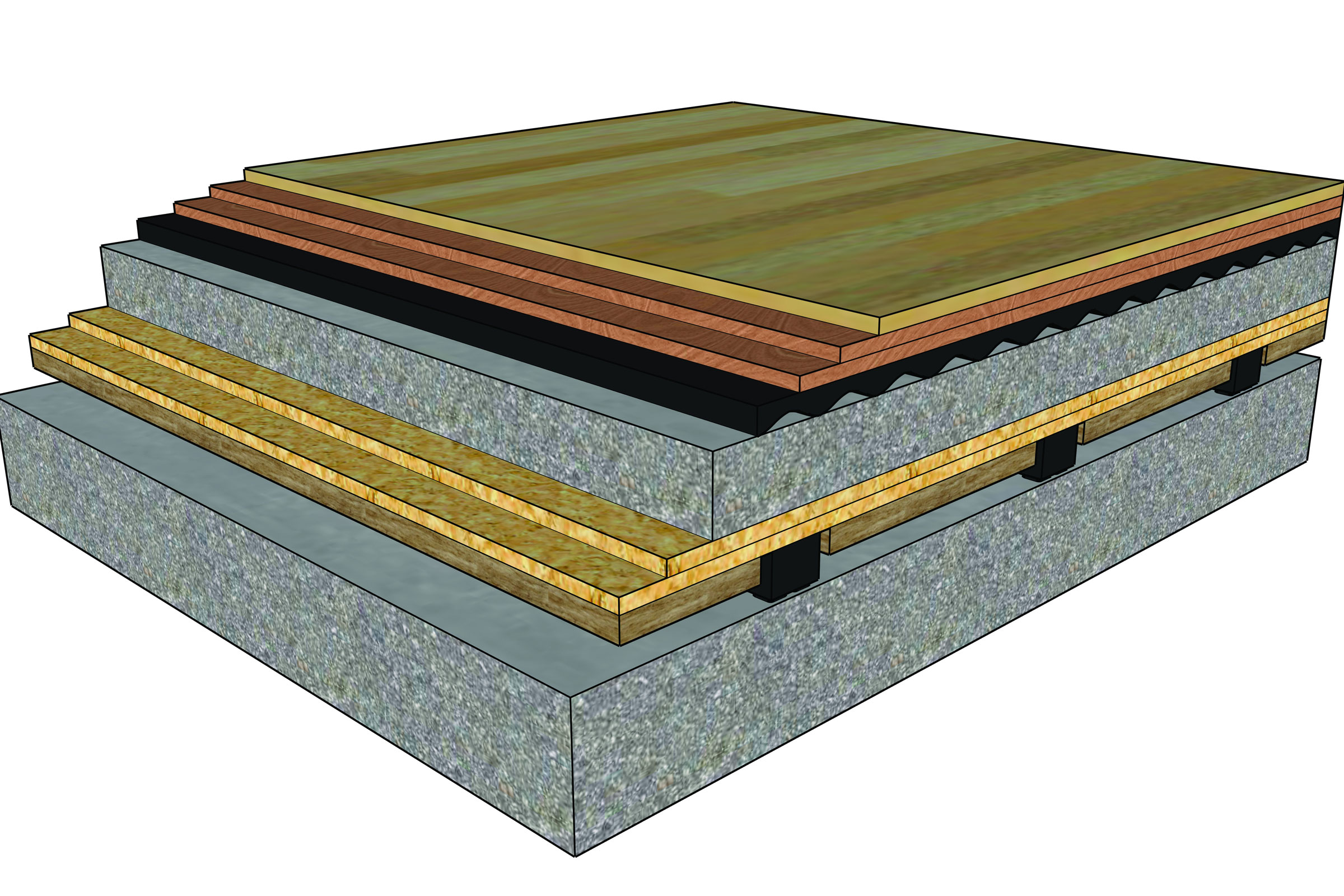

Floating floors and acoustic underlayments are another type of sound insulation. Floating floors are a type of floor assembly in which the finished floor is not secured to the subfloor by glue, staples, or nails—rather, the planks themselves are laid over a thin underlayment and secured to one another via adhesive or a locking system, essentially allowing them to “float” above the subfloor. Because floating floor systems are isolated from the subfloor, they drastically reduce the transfer of impact noise between floors.

Acoustic underlayments, on the other hand, are thin sound-blocking layers installed between a subfloor and finished floor. They often use materials such as rubber, concrete, or cork and reduce impact noise in spaces where there is heavy foot traffic or equipment being used.

Rubber

The REGUPOL sonusfit range (above floating concrete layer) has been acoustically tested and can be adapted accordingly to the different loads that occur in gyms. REGUPOL SoundPanel (below floating concrete level) helps block impact noises from traveling between floors. Image courtesy of REGUPOL

Thanks to rubber’s natural ability to absorb heavy impacts and their subsequent vibrations without sustaining damage, it is extremely well-suited for use in flooring systems as a means of reducing sound transmission, both as an underlayment and in floating floor assemblies. REGUPOL is a leading provider of rubber flooring solutions and offers a wide variety of products designed with acoustics in mind.

REGUPOL SoundPanel, for example, is a panelized floating floor system designed specifically to improve the acoustics of a space by preventing the transfer of sound between rooms. The system consists of a durable OSB panel with noise-insulating fiberglass attached to its underside, all of which rests on engineered rubber pucks. The pucks help support the flooring and ensure minimal contact with the subfloor while maximizing vibration absorption.

When installed between a 5-and-a-half-inch structural concrete slab and 4 inch floating concrete slab, SoundPanel has an STC rating ranging from 69 to 71 and an IIC rating ranging between 68 and 72, depending on the type used. REGUPOL currently offers SoundPanel in three types: x4-1 (1″), x4-1.5 (1.5″), and x4-2 (2″).

Sound Mat & Gypsum Concrete

Photo courtesy of USG

Today’s minimum requirements for sound transmission between dwelling units and other public areas in a building can be found in Section 1207 of the International Building Code. In a typical floor/ceiling assembly, the code minimum for sound transmission class (STC) is easy to achieve with materials like gypsum concrete. Gypsum concrete is created by mixing sand and gypsum composed of hydrated calcium sulfate. It occurs mainly in sedimentary deposits and is both mined and synthetically produced from cleaning the combustion gases of coal-burning power plants.

“The best way to dampen airborne sound, or STC, is mass, and the best mass is a high-density, crack-resistant cementitious material without control joints,” Alex MacDonald, manager of strategic accounts for USG, previously told gb&d. “With hard surface floor coverings like vinyl plank, ceramic tile, or engineered hardwood on the other hand, the IIC (Impact Isolation Class, which measures a floor assembly’s ability to absorb impact sound) will always fall below the code required 50 IIC when there is no sound mat. Placing a sound mat under the gypsum concrete decouples the gypsum concrete mass from the framing, ultimately making the difference between meeting or not meeting the IIC requirement of Section 1207.”

A sound mat and gypsum system can be applied under any type of flooring. “Right out of the box, USG’s Levelrock underlayment is going to meet code and allow you to use any floor covering you like,” Chicago-based architect Adam Thoma of HKM Architects + Planners previously told gb&d. While there are flooring products on the market with sound backing, they can be costly. “Gypsum underlayments installed over sound attenuation mats are very cost effective. That is the reason we use them,” Thoma says. “It is our go-to system and makes our lives easier.”

Mass timber projects can also benefit from concrete materials. A Maxxon Acousti-Mat sound mat topped with a Gyp-Crete®underlayment can help by offering a high-performance sound control system that doesn’t affect aesthetics. Gyp-Crete products are available in several formulas to meet the cost and floor strength requirements of any job.

“While often used in wood frame construction, our high strength underlayments are also excellent for smoothing concrete slabs or precast planks in new and renovation projects. Our Gyp-Crete products are typically poured at one inch deep over our Acousti-Mat line of sound control products,” Erik Holmgreen, vice president of research and development at Maxxon, told gb&d in a previous article.

This system provides excellent sound control as well as fire resistance. Maxxon’s Gyp-Crete and Acousti-Mat system is listed in 140 UL fire rated designs and backed by hundreds of published sound tests.

Cork

Cork underlayment is an excellent acoustic insulation. Photo courtesy of Corticeira Amorim

Cork is another underlayment material that acts as both thermal and acoustic insulation. Cork-based underlayments provide a thin profile and are ideal for hard surface, vinyl, and resilient flooring. These underlayments typically consist of agglomerated cork granules or agglomerated cork mixed with other recycled materials, such as tire-derived rubber, high density polyurethane, or EVA foam granules.

AcoustiCORK—a brand owned by Amorim Cork Composites—is a leading provider of cork-based acoustic insulation and vibration isolation products. The AcoustiCORK R60 Underlayment, for example, is only 6 mm thick but has an STC rating ranging from 52 to 64 and an IIC rating ranging between 50 and 69 depending on the type of subfloor, overlay, and floor covering.

Soundproof Windows & Doors

Photo courtesy of PGT Innovations

Because they are relatively thin in comparison to the rest of a wall assembly and represent breaks in a wall’s insulation layer, windows and doors are extremely common places for both airborne and flanking noise pollution to occur, allowing street-level sounds to enter a building and disturb its occupants.

Windows and window walls may be insulated by increasing their glazing count, with triple-paned windows being the most effective at blocking sound. The space between each pane acts as an insulation layer and is filled with either argon or some other inert gas that has a high insulation value. Increasing the thickness of the panes also helps prevent unwanted sounds from traveling through the glass.

And though they are thicker than windows, doors also represent weak points when it comes to airborne sound transmission. This can be remedied in part by choosing solid wood or solid-core doors over uninsulated hollow-core doors, but ultimately depends on the door’s frame, perimeter seals, and threshold. The ASSA ABLOY Group—a leading provider of locks, doors, gates, and entrance automation systems—offers a range of products that can help improve the sound blocking capabilities of door assemblies in both residential and commercial projects.

Acoustic Caulk

Just like air and moisture, however, sound can enter a building through gaps in improperly-sealed windows, doors, and other openings along a building’s exterior. This can be mitigated through the application of acoustic caulks.

Unlike conventional silicone-based caulk, acoustic caulk is a latex-based product that remains rubbery and flexible permanently instead of hardening after application. This inherent flexibility ensures that acoustic caulk will not shrink or crack over time—something silicone-based caulk is prone to doing—thereby creating a better, longer-lasting soundproofing barrier.

Jessica Powers contributed to this article.